The Importance of Drainage and Seepage Control in the Mining Industry

Groundwater administration is quintessential for making sure secure mine operations and environmental safety throughout mining operations. Improper drainage structures can lead to serious accidents such as slope instability, tunnel flooding, and tailings dam failure. Furthermore, positive seepage manipulate systems can forestall heavy metallic and acidic wastewater from contaminating the surrounding environment.

This article comprehensively introduces the various drainage and seepage control materials required by the mining industry and their innovative applications.

I. Basic Drainage Material System

1.1 Plastic Drainage Board Series

Tunnel Waterproofing Plastic Drainage Board: Designed specifically for mine tunnels, it features high compressive strength (up to 500 kPa) and excellent water conductivity (water conductivity > 0.5 cm²/s).

HDPE Drainage Board: Made of high-density polyethylene, it is resistant to acid and alkali corrosion and suitable for extreme environments with a pH range of 2-12.

Drainage Protection Board: Features a protective layer to prevent mechanical damage and boasts a service life of over 30 years.

Composite Drainage System: A third-dimensional shape that integrates drainage, filtration, and protection.

Geocomposite Drainage Board: Weighing solely 1.5-3.0 kg/m² per unit area, it boasts a tensile power of 200-400 kN/m.

3D Drainage Geocomposite: This innovative three-dimensional drainage structure improves drainage efficiency by 40% compared to traditional materials.

II. Advanced Seepage Control Material Solutions

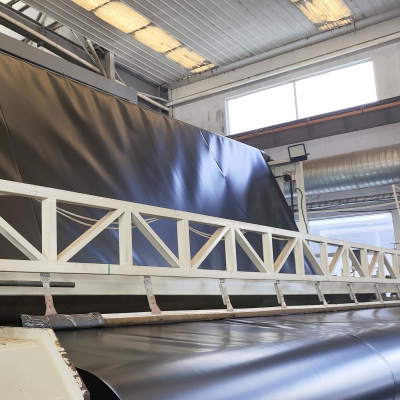

2.1 HDPE Geomembrane Series

HDPE Geomembrane Sheet: With a standard thickness of 1.0-3.0mm and an elongation at break exceeding 700%, it is the preferred anti-seepage material for tailings ponds.

Dual Color HDPE Geomembrane: The two-color design facilitates weld quality inspection and achieves weld strength up to 90% of the parent material.

Textured Composite Liner: The surface texture improves the friction coefficient by 50%, making it particularly suitable for steep slope applications.

2.2 Specialty Anti-seepage Materials

Chemical-resistant Geocomposite: Resistant to extreme chemical environments with a pH range of 1-14.

UV-resistant Composite Geomembrane: The addition of special anti-aging agents extends its outdoor service life to 25 years.

Root-resistant Membrane Liner: A special formula effectively prevents plant root penetration.

III. Innovative Applications of Composite Materials

3.1 Multi-layer Composite Structure

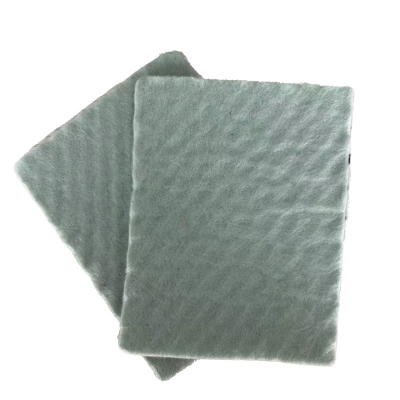

Geocomposite Two Cloth One Membrane: A typical structure of non-woven fabric/HDPE film/non-woven fabric provides both anti-seepage and drainage functions.

Double Geotextile Geomembrane: Double non-woven fabric structure protects the middle impermeable membrane from damage.

Reinforced composite membrane: Incorporates a glass fiber mesh for 300% increased puncture resistance.

3.2 Special Functional Composite Materials

Self-healing geocomposite: Contains a built-in microcapsule restoration agent to routinely restore minor cracks.

High-strength geocomposite liner: With a tensile electricity of up to eighty kN/m, appropriate for high-stress areas.

Eco-friendly composite liner: Made from recyclable materials, it meets green mine construction requirements.

IV. Three-Dimensional Drainage Network System

4.1 Three-Dimensional Drainage Structure

3D Drainage Network for Landfills: Core drainage channel height 5-10 mm, hydraulic conductivity > 0.01 m²/s

HDPE Geonet: Mesh sizes range from 5×5 mm to 10×10 mm, suitable for drainage needs of various particle sizes.

Composite Drainage Net: Composite structure with a long-term compression creep rate of <10%.

4.2 Professional Drainage Components

Drainage Nets: Auxiliary drainage materials used to form a complete three-dimensional drainage system.

Drain Netting: Lightweight drainage netting suitable for auxiliary drainage projects.

Net for Drainage: Basic drainage network with the best cost-effectiveness.

V. Special Application Solutions

5.1 Steep Slope Protection System

Geomembrane for Steep Slopes: Specially formulated to increase the coefficient of friction, suitable for slopes up to 1:1.5.

Geotextile-bonded geomembrane: Enhances interfacial stability and prevents slippage.

High-strength composite liner: Multi-layer composite structure with excellent anti-slip performance.

5.2 Extreme Environment Solutions

PP composite geomembrane: Polypropylene, temperature resistant from -30°C to 120°C.

Industrial Containment Liner: Industrial-grade anti-seepage standards, suitable for heavy metal pollution control.

Leak-proof Geomembrane Liner: A double-layer detection structure with a leak detection accuracy of 1×10⁻⁵cm/s.

VI. Material Selection Technical Guidelines

6.1 Key Performance Indicators

Hydraulic Conductivity: Drainage substances ought to be >1×10⁻³m/s

Seepage Coefficient: Seepage-proofing substances need to be <1×10⁻¹¹cm/s

Tensile Strength: 30-80kN/m, relying on assignment requirements

Thickness: 1.0-3.0mm is a frequent vary in the mining industry.

6.2 Selection Decision Matrix

Application Scenario | Preferred Material | Alternative Options | Key Indicators |

Tailing Pond Seepage Control | HDPE Geomembrane Sheet | Seepage Coefficient <1×10⁻¹²cm/s | |

Gateway Drainage | Geocomposite Drainage Board | 3D Drainage Network | Hydraulic Conductivity >0.1cm²/s |

Steep Slope Protection | Textured composite liner | Geomembrane for Steep Slopes | Friction Coefficient >0.5 |

Acidic Environment | Chemical-resistant geocomposite | PP composite geomembrane | pH 1-3 |

VII. Project Case Studies

7.1 Copper Mine Tailings Pond Project

By using HDPE Geomembrane Sheet (2.0mm thickness) in conjunction with Geocomposite Drainage Board, we were able to successfully control leakage to <0.5L/ha·d, far below the industry standard.

7.2 Deep Coal Mine Tunnel Project

A combined system of Tunnel Waterproofing Plastic Drainage Board and High-Strength Composite Liner effectively addressed drainage and anti-seepage challenges under high water pressure (0.8MPa).

7.3 Steep Slope Management

Applying Geomembrane for Steep Slopes (1:1.25 slope) and 3D Drainage Geocomposite, the slope stability coefficient was increased from 0.95 to 1.35.

VIII. Future Development Trends

Intelligent Materials: Geocomposite liners embedded with sensors can monitor leakage in real time.

Environmentally Friendly Products: The market share of eco-friendly composite liners is expected to grow by 15% annually.

High-Performance Composite Materials: Self-healing geocomposite will become the mainstream choice for mine remediation.

Standardization: Improvements to ASTM requirements for composite liners will pressure enterprise progress.

IX. Conclusions & Recommendations

Mining drainage and anti-seepage tasks require choosing the most terrific fabric aggregate primarily based on particular geological conditions, hydrological conditions, and venture requirements. Recommendations:

Prioritize the comprehensive performance advantages of the Geocomposite series of products.

Use specialty materials such as high-strength and chemical-resistant materials in key areas.

Emphasis be placed on long-term performance indicators such as UV resistance and root resistance.

Perform regular Geocomposite seam testing to ensure project quality.

Through scientific fabric choice and standardized construction, modern-day drainage and anti-seepage substances can substantially enhance mine security and environmental performance, offering a stable basis for the sustainable improvement of the mining industry.