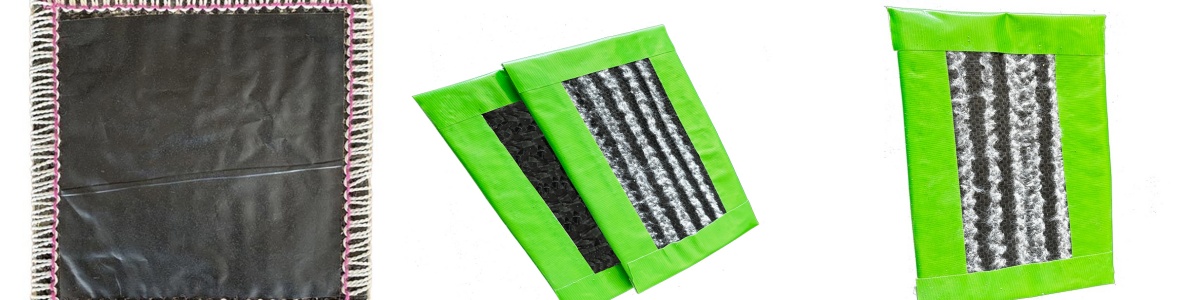

Product Introduction:

Haoyang Environmental's innovative prefabricated bentonite panels revolutionize containment system installation with their modular 1m×2m sections featuring advanced peel-and-stick seam technology. These factory-assembled units incorporate a high-swelling sodium bentonite core (≥24mL/2g) bonded between reinforced polypropylene geotextiles, enabling rapid deployment at rates exceeding 300m²/hour - ideal for emergency spill containment, flood protection barriers, and time-sensitive remediation projects. The pre-applied pressure-sensitive adhesive strips eliminate traditional seaming requirements while maintaining ≤5×10⁻¹¹ m/s permeability, with field validation showing 98% seam integrity even under 50kPa shear stress.

![Textured Membrane-Protected Bentonite Liner Textured Membrane-Protected Bentonite Liner]()

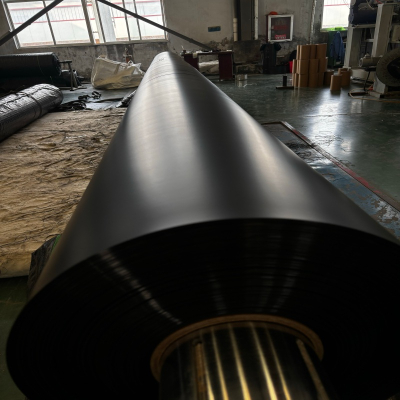

Product Applications:

1. Landfill liners - Prevent leachate contamination using high-density geomembranes with excellent chemical resistance.

2. Road construction - Reinforce weak subgrades and separate soil layers with durable woven geotextiles.

3. Erosion control - Stabilize slopes using permeable geotextiles that allow vegetation growth.

![Textured Membrane-Protected Bentonite Liner Textured Membrane-Protected Bentonite Liner]()

Product Performance Guarantees

1. 50-Year Service Life (GRI-GCL3 Certified)

Backed by accelerated aging tests simulating half-century performance under: Cyclic hydration/dehydration (ASTM D5887) & Sustained 150kPa overburden pressure (GRI GM19) & Chemical exposure to pH 2-12 solutions

Includes 10-year material warranty with optional extended coverage

2. Enhanced UV Stability (≥12 Months Exposure)

Proprietary UV-stabilized polypropylene geotextiles: Retain ≥90% tensile strength after 5000 MJ/m² UV exposure (ASTM D4355) & Incorporate carbon black/HALS stabilizers for maximum protection

Field-validated in Middle East solar farms and Australian outback projects

3. Extreme Temperature Tolerance (-40°C to 120°C)

Arctic-grade formulation tested to: 100 freeze-thaw cycles without bentonite degradation & high-temperature stability exceeding geomembrane standards

Specialized versions available for: Cryogenic LNG containment (-196°C) & Bituminous paving applications (160°C peak)

Technical Support Services

Site-specific installation simulations using finite element analysis.

Custom permeability formulations (10⁻⁸ to 10⁻¹² m/s adjustable.

Lifetime performance monitoring via embedded sensor arrays.

Business Strength:

Haoyang Environmental maintains a vertically integrated quality assurance system that begins with stringent raw material screening and continues through every production stage to final certification. Our ISO 17025-accredited laboratory conducts comprehensive testing, including swell index verification, hydraulic conductivity measurement, and accelerated aging simulations, ensuring all geosynthetics meet or exceed GRI and ASTM standards before shipment. Advanced monitoring systems track production parameters in real-time, while RFID-enabled traceability provides complete documentation from factory to installation site. This rigorous approach has achieved a 99.9% reliability rate across major infrastructure projects worldwide, supported by third-party validation and continuous performance monitoring throughout each product's service life.

![Textured Membrane-Protected Bentonite Liner Textured Membrane-Protected Bentonite Liner]()