HDPE Liner Sheet: Core Selection and Implementation Points of Engineering Anti-Seepage Technology

In the fields of environmental engineering and infrastructure construction, the reliability of seepage prevention systems directly determines the long-term safety and environmental effectiveness of projects. Through practical verification in numerous projects, HDPE Liner Sheets have become the preferred solution for various seepage prevention projects. This high-density polyethylene geomembrane, with its unique material properties and engineering adaptability, has demonstrated superior performance in projects such as landfills, artificial lakes, and mine tailings dams. This article will systematically analyze the technical advantages and key implementation points of HDPE Liner Sheets from three dimensions: material properties, application scope, and construction technology, based on engineering practice experience.

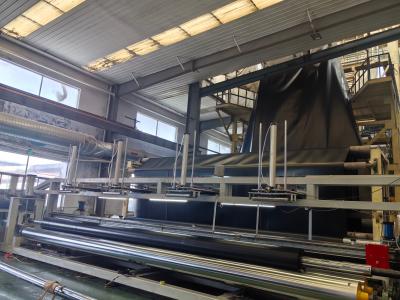

|  |  |

Material Properties: Engineering Performance Analysis of HDPE Geomembrane

From a materials science perspective, the performance advantages of HDPE Liner Sheets stem from its unique molecular structure. The linear molecular chain structure of high-density polyethylene gives it high crystallinity, thus endowing the material with excellent physicochemical properties.

In practical engineering applications, HDPE membrane sheets exhibit the following key characteristics:

1.Chemical Corrosion Resistance: Laboratory tests and field verification have demonstrated that this material exhibits significant resistance to acids, alkalis, salts, and other chemicals, maintaining stability even in extreme environments with pH values ranging from 2 to 13. Monitoring data from a chemical industrial park's seepage prevention project shows that after five years of continuous operation, the material performance degradation rate of collection tanks using HDPE membrane sheets is less than 3%.

2.Mechanical Strength and Durability: Standard HDPE liner sheets have an elongation at break exceeding 700%, enabling them to withstand moderate foundation deformation. In a project in a seasonally frost-heavy region in northern China, monitoring results showed that the material maintained structural integrity after six freeze-thaw cycles.

3.Environmental Stress Cracking Resistance: Through optimized resin formulation and processing technology, modern HDPE Geomembrane Sheet exhibits environmental stress cracking resistance exceeding 2000 hours under long-term static loads, far surpassing the requirements of foundation engineering.

Application Scope: Engineering Practices of HDPE Membrane Sheet

In current engineering practice, the application of HDPE Liner Sheet has expanded from traditional landfills to several emerging fields.

1.Hydraulic Engineering Applications: In a large reservoir seepage prevention project in a southern province, 1.5mm thick HDPE Membrane Sheet was used as the main seepage prevention layer, effectively controlling leakage to below 0.2L/m² per day. The successful implementation of this project demonstrates the reliability of this type of material in large-scale hydraulic engineering projects.

2.Mining Environmental Protection Engineering: The tailings dam seepage prevention system of a metal mine uses a double-layer HDPE Geomembrane Sheet structure with a leakage detection layer in between. System operation monitoring data shows that the seepage prevention efficiency reaches over 99.8%, effectively preventing heavy metal ion pollution of groundwater.

3.Ecological Protection Project: In the construction of wetland protection areas, the application of HDPE Liner Sheet achieved precise water level control. Project monitoring data shows that after using this material, the water level fluctuation range of the protection area decreased by 70%, creating a stable habitat for migratory birds.

Construction Technology: Key Points for Quality Control of HDPE Geomembrane Sheet

High-quality materials must be paired with standardized construction techniques to achieve their designed performance. The construction quality control of HDPE Geomembrane Sheet should focus on the following aspects:

1.Foundation Treatment Requirements: The flatness and density of the base layer directly affect the long-term stability of the seepage prevention system. According to engineering practice, the flatness of the base layer should be controlled within 30mm/2m, and there should be no sharp objects protruding. Experience from a certain project shows that every 10% increase in investment during the base layer treatment stage can reduce subsequent maintenance costs by more than 35%.

2.Welding Process Control: The connection quality of HDPE Liner Sheet determines the integrity of the seepage prevention system. When using a double-track hot-melt welding process, the weld strength should be no less than 90% of the base material strength. A large-scale project established a strict welding quality inspection system, conducting air pressure tests on all welds and performing a destructive test on every 500 meters of weld to ensure the integrity of the system.

3.Protective Layer Setup: A reasonable protective layer design can significantly extend the service life of HDPE membrane sheets. Engineering experience shows that placing appropriate geotextile protective layers above and below the material can improve the system's puncture resistance by more than 50%. A project in northern China incorporated a root barrier design into the protective layer, effectively preventing plant roots from damaging the seepage barrier.

Conclusion:

From material performance to engineering practice, HDPE membrane sheets demonstrate comprehensive advantages as a core material for modern seepage control projects. In today's increasingly stringent environmental requirements, correctly selecting material specifications and strictly adhering to construction standards are crucial to ensuring the long-term effectiveness of seepage control systems. Engineering practice shows that high-quality HDPE membrane sheets, combined with standardized construction techniques, can provide a reliable service life of over 30 years, providing lasting protection for various environmental protection and infrastructure projects.