Products Introduce:

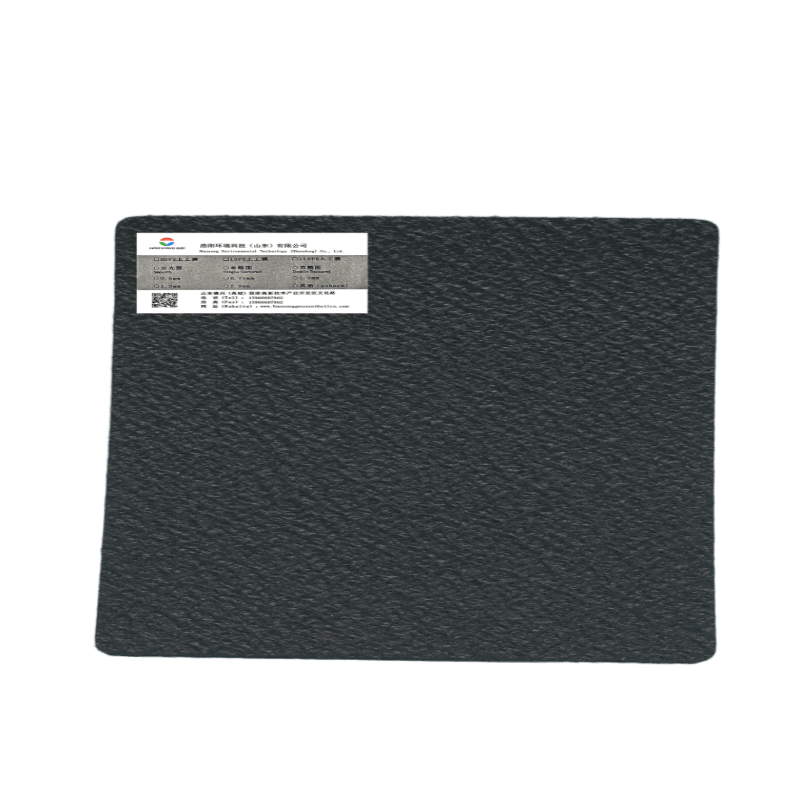

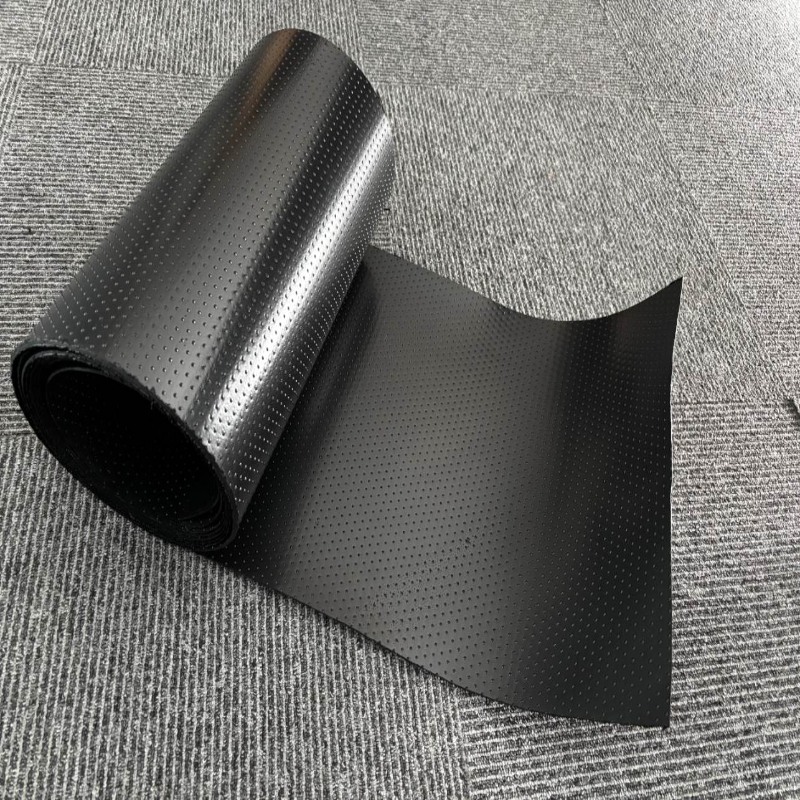

Rough HDPE geomembrane is an innovative seepage control material, available in single or double roughness designs to enhance friction and anti-slip properties. This makes it particularly suitable for steep slopes and vertical seepage control applications, improving project stability.

HDPE geomembrane offers excellent temperature adaptability, weldability, weather resistance, and aging resistance. It also provides strong chemical corrosion resistance, environmental stress crack resistance, and puncture resistance. These properties make it ideal for use in underground engineering, mining projects, landfills, and sewage or waste treatment sites as a reliable anti-seepage material.

Product Parameters:

Main performance and technical indicators |

Technical Performance Indicators of HDPE Shih Wang Sense of Garbage Pei Li Field Width (CJ-T234-2006) |

Serial No. | Value | Measured Value |

1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

1 | Height of Gross Finish/mm | 0.25 |

2 | Least density(g/cm2) | 0.939 |

3 | Tensile properties |

|

Yield strength (stress) (N/mm) | 15 | 18 | 22 | 29 | 37 | 44 |

Rupture strength (stress) (N/mm) | 10 | 13 | 16 | 21 | 26 | 32 |

Yield elongation/% | 12 |

Elongation at break/% | 100 |

4 | Right angle tear strength/N | 125 | 156 | 187 | 249 | 311 | 374 |

5 | Puncture strength/N | 267 | 333 | 400 | 534 | 667 | 800 |

6 | Mine environmental stress cracking (single point |

| 300 |

|

Notched Fear Load Tensile Method)/h |

7 | Soot |

|

Carbon black content (range) / % | 2.0~3.0 |

Carbon black dispersion | 9 out of 10 observation areas should be in level 1 or 2, and no more than 1 should be in level 3 |

8 | Oxidation Induction Time (OIT) |

|

Standardized OIT/min | 100 |

Oppressive OIT/min | 400 |

9 | 85°C oven aging (minimum average) |

|

Retention/% of standard OIT after 90 d of baking | 55 |

Retention/% of high-pressure OIT after 90 d of baking | 80 |

10 | UV strength |

|

Retention/% of standard OIT after 1600h of external irradiation with vectors | 50 |

Retention/% of high-pressure OIT after 1600h of UV galling | 50 |

11 | -70℃ low-temperature impact performance | Pass |

12 | Water vapor permeability coefficient g-cm/(cm2-s-Pa) | ≤1.0×10(-13) |

13 | Dimensional stability/% | ±2 |

Product Applications:

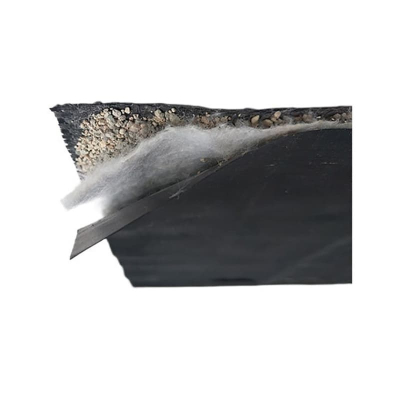

1. Landfill, Sewage, and Slag Treatment: Seepage control for waste management.

2. Water Conservancy Projects: River embankments, lake dams, tailings dams, sewage dams, reservoirs, channels, and liquid storage ponds.

3. Underground Structures: Seepage control for subways, basements, tunnels, and tunnel linings.

4. Road and Foundation Engineering: Salt seepage control for roadbeds and foundations.

5. Hydraulic Structures: Horizontal seepage control for embankments, vertical seepage control for dams, construction cofferdams, and waste yards.

6. Aquaculture: Seawater and freshwater farming ponds.

7. Transportation Infrastructure: Roads, highways, railways, and foundations with waterproof layers for expansive soils and humid loess.

8. Roofing: Roof seepage control for buildings.

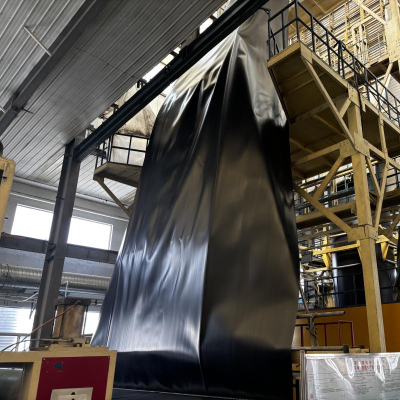

Company Strength:

Haoyang Environmental Technology ( Shandong ) Co., Ltd. has over 20 contemporary environmental safety engineering fabric manufacturing lines, with merchandise inclusive of polyethylene geomembrane, non-woven fabric/woven cloth composite geomembrane, artificial filament spunbond and needle-punched nonwoven geotextiles, artificial staple fibers needle-punched nonwoven geotextiles, three-d composite drainage net, sodium bentonite geosynthetic clay liner, 10-meter roughened geomembrane, and almost a hundred of different types.