Product Introduction:

Our HDPE Composite Geomembrane is a state-of-the-art solution meticulously engineered to meet the stringent requirements of waste containment. At its core, this composite liner features a unique design that integrates a bentonite layer between a high-density polyethylene (HDPE) geomembrane and a geotextile. The HDPE geomembrane, renowned for its exceptional chemical resistance, impermeability, and durability, forms the primary barrier against the passage of liquids and gases. It effectively prevents the leakage of hazardous substances, making it an ideal choice for applications where containment is of utmost importance.

Sandwiched between the HDPE geomembrane and the geotextile, the bentonite layer is the key to the liner's self-sealing capabilities. Bentonite, a type of clay with remarkable swelling properties when it comes into contact with water, automatically repairs minor punctures or cracks in the liner. When a puncture occurs, the bentonite swells and fills the void, creating a tight seal that restores the integrity of the containment system. This self-sealing mechanism provides an added layer of protection, ensuring reliable defense against leachate migration in landfill applications and other waste containment scenarios.

The geotextile layer, on the other hand, serves multiple purposes. It provides mechanical reinforcement to the composite liner, enhancing its tensile strength and resistance to tearing. Additionally, it acts as a filter, preventing soil particles and other debris from passing through while allowing water to drain freely. This helps to maintain the stability of the surrounding soil and prevent clogging of the drainage system, further contributing to the overall performance and longevity of the HDPE Composite Geomembrane.

![HDPE Composite Geomembrane HDPE Composite Geomembrane]()

Product Applications:

1. Solar Pond Liners - Specially formulated for concentrated solar power plants.

2. Geothermal Containment - High-temperature resistant liners for geothermal fluids.

3. Coal Ash Impoundments - Containment systems for coal combustion residuals.

![HDPE Composite Geomembrane HDPE Composite Geomembrane]()

Product Features

Self-Sealing Mechanism: The unique integration of the bentonite layer gives the HDPE Composite Geomembrane its self-sealing capabilities. This feature ensures that minor punctures or cracks are automatically repaired, providing continuous protection against leakage and maintaining the integrity of the containment system.

Excellent Chemical Resistance: The HDPE geomembrane offers outstanding resistance to a wide range of chemicals, acids, and alkalis. This makes it suitable for use in applications where the liner may come into contact with corrosive substances, such as in waste containment and geothermal applications.

High Tensile Strength: The combination of the HDPE geomembrane and the geotextile layer provides the composite liner with high tensile strength. This allows it to withstand mechanical stresses, ground movement, and other external forces without tearing or deforming, ensuring long-term durability.

Effective Filtration and Drainage: The geotextile layer acts as a filter, preventing soil particles and debris from passing through while allowing water to drain freely. This helps to maintain the stability of the surrounding soil and prevent clogging of the drainage system, ensuring the proper functioning of the containment system.

Quality Assurance:

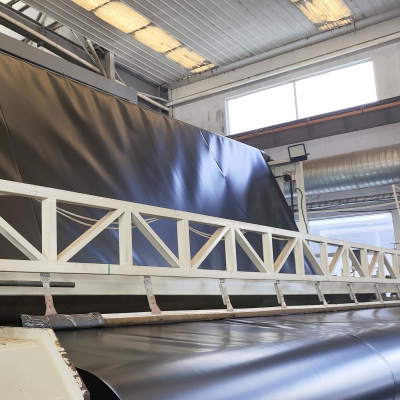

At our company, quality is the cornerstone of our manufacturing process. We combine advanced manufacturing technology with rigorous quality control measures to produce HDPE Composite Geomembranes that meet the highest standards of durability and reliability.

Our manufacturing facilities are equipped with state-of-the-art equipment and technology, allowing us to produce geosynthetic products with precision and consistency. We source only the highest-quality raw materials, including HDPE polymers, bentonite clay, and geotextile fabrics, from trusted suppliers. Each batch of raw materials undergoes strict quality testing to ensure its suitability for use in our products.

During the manufacturing process, every stage is closely monitored and controlled to ensure that the final product meets our stringent quality requirements. Our quality control team conducts regular inspections and tests, including tensile strength testing, permeability testing, swelling capacity testing of the bentonite layer, and adhesion testing between the layers. These tests are carried out in accordance with international standards and industry best practices, ensuring that our HDPE Composite Geomembranes are of the highest quality.

Technical Services:

Our technical team provides comprehensive support throughout the project lifecycle. At the project planning stage, we work closely with clients to understand their specific needs, site conditions, and project requirements. Based on this information, we offer detailed product selection advice, customized design solutions, and technical specifications tailored to each project. Our experts can also assist with site surveys, feasibility studies, and the development of installation plans to ensure the optimal performance of our HDPE Composite Geomembrane.

During the installation process, our experienced technicians are available to provide on-site guidance and training. We ensure that the installation teams are well-versed in the proper handling, cutting, seaming, and anchoring techniques of the composite liner. Our technicians can also oversee the installation process to ensure that it is carried out in accordance with the recommended procedures and industry best practices, minimizing the risk of installation errors and ensuring the long-term performance of the liner.

Post-installation, we offer continuous technical support. We conduct regular inspections to monitor the performance of the HDPE Composite Geomembrane and provide maintenance recommendations as needed. In the event of any issues or concerns, our technical team responds promptly, providing timely solutions and assistance to ensure the continued effectiveness of the containment system.

Business Strength:

Our company's strength lies in our ability to combine advanced manufacturing technology with rigorous quality control. We invest heavily in research and development to continuously improve our manufacturing processes and product performance. Our team of experienced engineers and technicians is dedicated to developing innovative geosynthetic solutions that meet the evolving needs of our customers.

By using the latest manufacturing technology, we are able to produce HDPE Composite Geomembranes with consistent quality and performance. Our rigorous quality control measures ensure that every product that leaves our factory meets or exceeds industry standards. This commitment to quality has earned us a reputation as a reliable supplier of geosynthetic products, and we are trusted by customers worldwide to provide durable and effective containment and reinforcement solutions.

In addition to our technical expertise and quality products, we also offer excellent customer service. We work closely with our customers throughout the project lifecycle, providing them with the support and guidance they need to ensure the success of their projects. Whether it's helping with product selection, providing technical advice, or offering after-sales support, we are committed to delivering a high level of customer satisfaction.

![HDPE Composite Geomembrane HDPE Composite Geomembrane]()