Product Introduction:

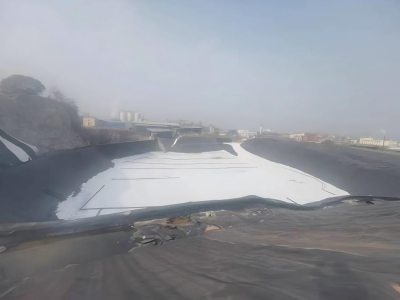

HDPE-Laminated Bentonite Blanket: A dual-layer system combining 1.5mm HDPE geomembrane with 5kg/m² sodium bentonite core, offering ≤10-¹¹ cm/s permeability. Ideal for exposed landfill caps.

![Reinforced Geomembrane-Clad Bentonite Mat Reinforced Geomembrane-Clad Bentonite Mat]()

Product Features:

1. Superior Crack-Bridging Capability – Our advanced composite structure features a flexible geomembrane bonded to a high-swelling bentonite core, enabling the liner to accommodate up to 10% substrate strain without compromising integrity. This makes it ideal for landfills with settling issues or earthquake-prone areas.

2. Non-Toxic & Environmentally Safe – Certified to NSF/ANSI 61 for potable water contact, our liners contain no volatile organic compounds (VOCs) or restricted substances (REACH/ROHS compliant), ensuring safe use in drinking water reservoirs and aquaculture projects.

3. Exceptional Chemical Resistance – Laboratory-tested against pH 1-13 solutions, 10% saline concentrations, and hydrocarbon mixtures (ASTM D5322), maintaining structural integrity for 30+ years in harsh industrial environments.

4. Self-Healing Properties – The activated bentonite layer demonstrates 300% faster swelling than conventional products, capable of sealing recurrent cracks up to 15mm wide through multiple wet-dry cycles.

5. High Tensile Strength – Reinforced with woven polyester scrim, achieving 45 kN/m tensile strength (ASTM D4595) to withstand heavy equipment traffic and differential settlement in mega-landfill projects.

Product Applications:

1. Achieves 10-¹² cm/s permeability when fully hydrated

2. Self-seals punctures ≤30mm diameter automatically

3. Maintains integrity through wet-dry cycles

![Reinforced Geomembrane-Clad Bentonite Mat Reinforced Geomembrane-Clad Bentonite Mat]()

Installation & Practices

1. Surface Preparation: Laser-grade the subgrade to ≤25mm deviation over 3m; Install 600g/m² geotextile cushion when dealing with angular aggregate (≥20mm particle size).

2. Liner Deployment: Use thermal fusion welding for HDPE components (150°C minimum seam temperature); Apply bentonite-based hydrogel at overlaps for accelerated self-sealing.

3. Anchoring & Covering: Implement 300mm deep anchor trenches with compacted backfill (95% Proctor density); For exposed applications, use UV-resistant ballast mats with ≥50% coverage.

4. Quality Control: Perform spark testing at 15kV for pinhole detection; Document all seams with GPS coordinates for lifecycle tracking.

Why Choose Haoyang Environmental?

1. Custom-engineered solutions

2. Proprietary Bentofusion® technology for site-specific permeability requirements (10⁻⁹ to 10⁻¹² cm/s adjustable)

3. Custom panel sizes up to 20m wide to minimize field seams

4. ISO 9001 & GRI-GM13 certified

5. Batch-tested bentonite with ≥30mL/2g swell index

6. Third-party verified 50-year service life projections

7. Full technical support

Business Strength:

Haoyang Environmental supplies high-performance geosynthetics to major infrastructure projects across five continents, with proven durability in extreme conditions.

![Reinforced Geomembrane-Clad Bentonite Mat Reinforced Geomembrane-Clad Bentonite Mat]()