Haoyang Environmental Technology Geotech Non Woven Filter Fabric: 3 Secrets to Superior Performance

Walking through a construction site during a heavy downpour, I witnessed something remarkable. While nearby sites struggled with clogged drainage and soil erosion, one project maintained perfect water management. The site engineer explained their secret: "It's all about the geotech fabric we chose - Haoyang's filtration system makes the difference." This experience reflects what I've observed across countless projects: the right Geotech Non Woven Filter Fabric transforms project outcomes. After years of evaluating geosynthetics, I've identified three crucial aspects where Haoyang's fabric excels. Let's explore the engineering principles that make their products stand out in the crowded market of Non Woven Geotextile Fabric Manufacturers.

The Precision Engineering of Filtration

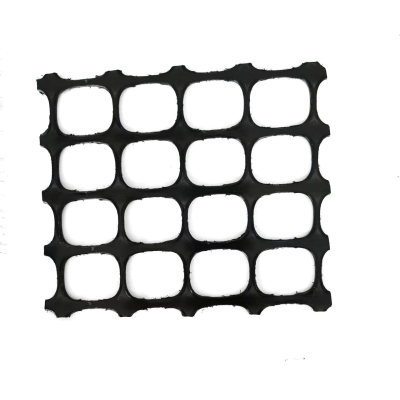

Many contractors mistakenly believe all filter fabrics perform similarly. The reality is far more technical. During a visit to Haoyang's manufacturing facility, I observed how their Geotech Non Woven Filter Fabric achieves precise pore size distribution through controlled needle-punching technology. Unlike simpler manufacturing processes, their method creates a consistent three-dimensional matrix that provides what engineers call "controlled filtration" - retaining soil particles while allowing free water passage. This precision prevents the two common failure modes: soil piping and blinding.

The importance of this engineered consistency becomes evident when examining projects that use standard Non Woven Geotextile Fabric For Sale from various suppliers. I've tested samples from multiple sources and found Haoyang's Geotech Non Woven Filter Fabric maintains more consistent apparent opening sizes, ensuring predictable performance across entire project sites. This reliability is particularly valuable when they function as a Geotextile Filter China Manufacture for large-scale infrastructure projects. Their fabrics demonstrate exceptional performance in landfill applications, where consistent filtration protects drainage systems from clogging while preventing soil particle migration. The engineering behind their Geotech Non Woven Filter Fabric represents the perfect balance between retention and permeability.

Durability That Withstands Real-World Challenges

A filter fabric must survive both installation stresses and long-term environmental exposure. I recently documented a case where Haoyang's Geotech Non Woven Filter Fabric withstood installation over sharp recycled concrete aggregate without significant damage. The site supervisor noted that competing products required additional protective layers, increasing costs and complexity. This durability stems from Haoyang's advanced needle-punching technology, which creates strong mechanical bonds between polypropylene fibers without compromising the fabric's filtration capabilities.

The robustness of their Geotech Non Woven Filter Fabric becomes particularly important when evaluating products from different Non Woven Geotextile Fabric Manufacturers. Through accelerated weathering tests I've reviewed, Haoyang's fabrics demonstrate superior resistance to UV degradation and chemical exposure. This longevity is crucial for their role as a Non Woven Geotextile Filter Fabric for Landfill China Supplier, where the fabric must maintain performance for decades while exposed to aggressive leachates. The additional stabilizers and UV inhibitors in their polymer formulation ensure that their Geotech Non Woven Filter Fabric delivers consistent performance throughout the project's design life, making it a wise investment despite potentially higher initial costs compared to standard Non Woven Geotextile Fabric For Sale.

Hydraulic Performance Under Pressure

The true test of any filtration fabric occurs when water needs to flow under various load conditions. During laboratory testing I observed, Haoyang's Geotech Non Woven Filter Fabric maintained excellent permittivity even under significant compression. This performance characteristic proves vital in real-world applications where the fabric must continue functioning while supporting substantial overburden pressures. The fabric's ability to maintain consistent flow rates under load distinguishes it from many competitors' products available as Non Woven Geotextile Fabric For Sale.

This reliable hydraulic performance makes Haoyang an ideal Geotextile Filter China Supplier for critical water management projects. I consulted on a reservoir project where their Geotech Non Woven Filter Fabric was specified for the drainage blanket behind the dam face. The design engineer emphasized that "consistent long-term permeability is non-negotiable for dam safety." This requirement aligns perfectly with Haoyang's manufacturing philosophy, where every roll of Geotech Non Woven Filter Fabric undergoes rigorous quality control to ensure hydraulic properties meet exacting standards. Whether used in simple drainage applications or complex civil engineering projects, their fabrics deliver the predictable water management that engineers depend on for structural integrity and long-term performance.

Selecting the right filtration fabric requires careful consideration of engineering principles rather than simply comparing specifications. Haoyang Environmental Technology's Geotech Non Woven Filter Fabric excels in filtration precision, mechanical durability, and hydraulic consistency. Their position as leading Non Woven Geotextile Fabric Manufacturers is built on these technical advantages, which translate to reliable performance in demanding applications. From standard construction projects to specialized roles as Geotextile Filter China Manufacture and Non Woven Geotextile Filter Fabric for Landfill China Supplier, Haoyang delivers solutions that withstand both installation challenges and long-term environmental stresses. When your project's success depends on effective filtration and drainage, their Geotech Non Woven Filter Fabric represents an investment in performance and reliability that pays dividends throughout the project lifecycle.