Introduction:

Our Nonwoven Geotextile Composite Geomembrane is an innovative two-layer geosynthetic material that combines the impermeability of a high-quality geomembrane with the protective filtration of a nonwoven geotextile. This engineered composite solution delivers superior performance in containment and protection applications across multiple industries.

![Nonwoven Geotextile Composite Geomembrane Nonwoven Geotextile Composite Geomembrane]()

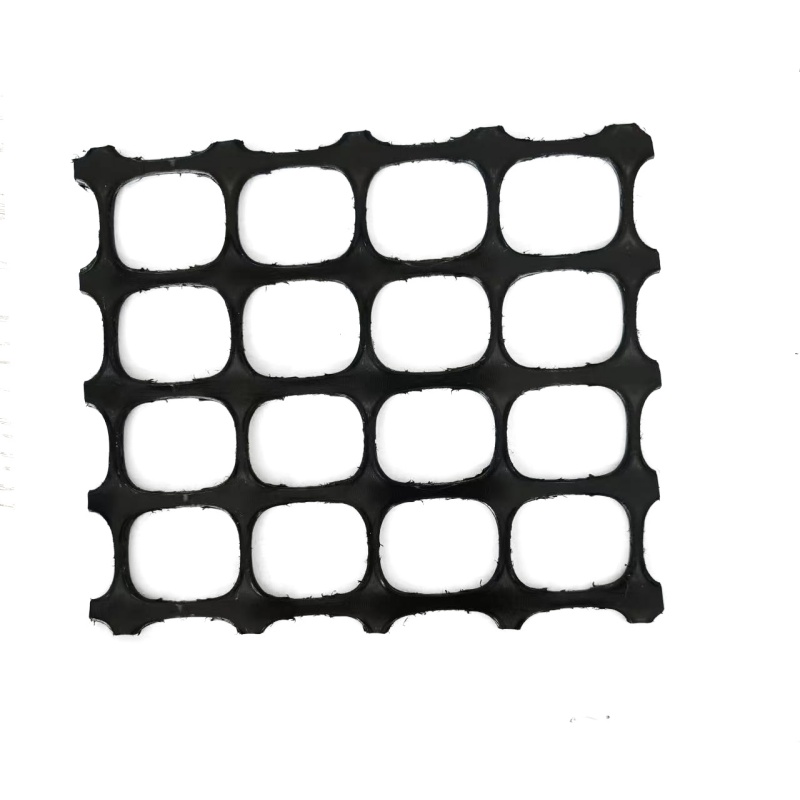

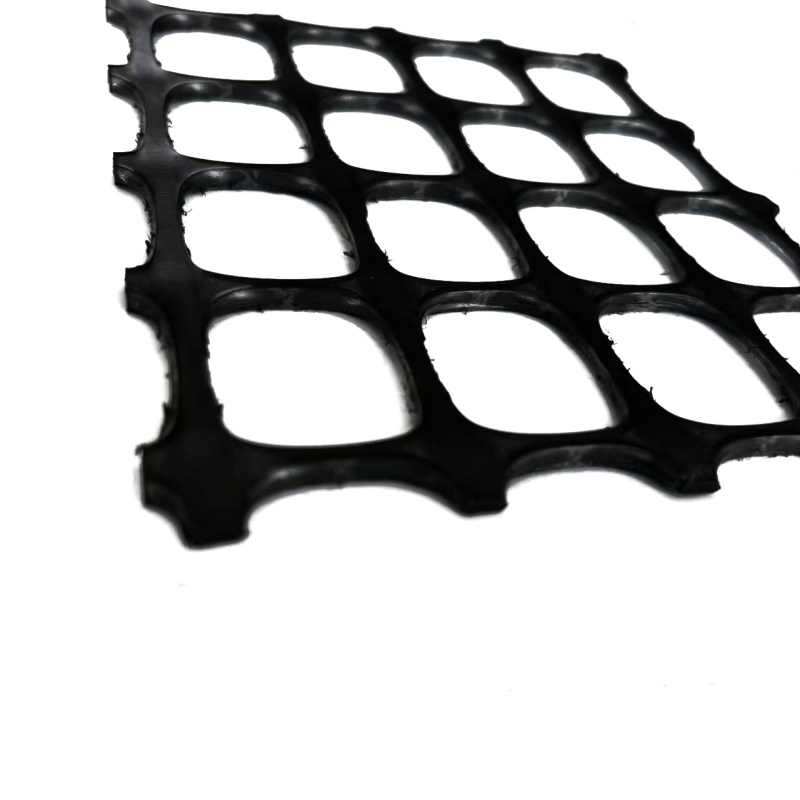

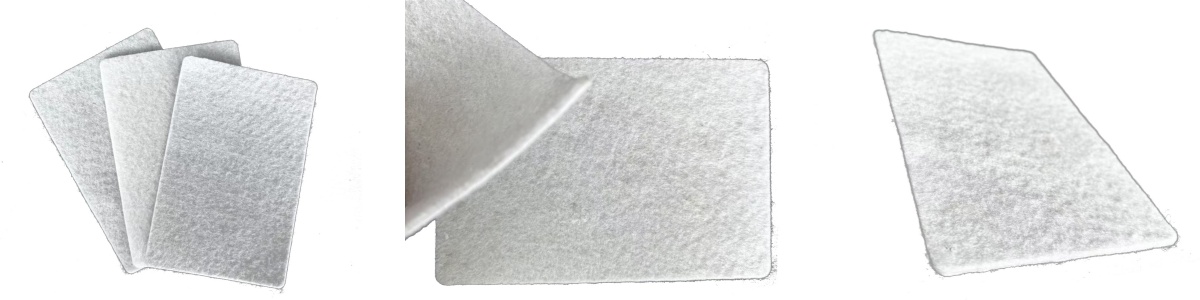

Structure & Composition:

Upper Layer: High-strength nonwoven geotextile (100-600g/m²)

Base Layer: Premium geomembrane (HDPE/LLDPE/PVC, 0.5-3.0mm)

Bonding Method: Advanced thermal lamination process ensures secure layer integration

Technical Specification:

Parameter | Specification |

Material | Polypropylene geotextile + HDPE/LLDPE/PVC geomembrane |

Geotextile Weight | 100 - 600 g/㎡ (customizable) |

Geomembrane Thickness | 0.5 - 3.0mm |

Tensile Strength | 15 - 40 kN/m (MD & CD) |

Tear Resistance | ≥ 100 N (ASTM D1004) |

Puncture Resistance | ≥ 400 N (ASTM D4833) |

Permeability | ≤ 1×10⁻¹³ cm/sec (geomembrane layer) |

UV Resistance | ≥ 80% strength retention after 500 hrs exposure |

Temperature Range | -40°C to +80°C |

Primary Applications:

1. Environmental Protection:

Landfill base liners and caps

Hazardous waste containment

Industrial wastewater ponds

2. Water Conservancy:

3. Mining & Energy:

Heap leach pads

Tailings pond liners

Oilfield containment

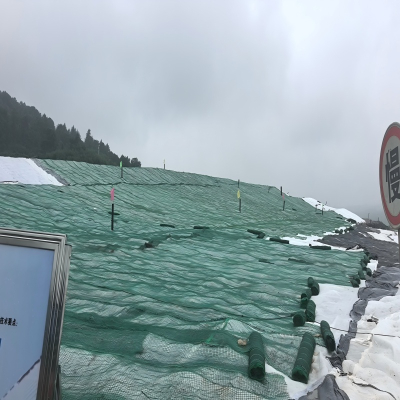

4. Civil Engineering:

![Nonwoven Geotextile Composite Geomembrane Nonwoven Geotextile Composite Geomembrane]()

![Nonwoven Geotextile Composite Geomembrane Nonwoven Geotextile Composite Geomembrane]()

Why Choose Our Product?

Dual Functionality: Combines impermeability with filtration

Enhanced Durability: 2-3× longer service life than single-layer membranes

Cost Efficiency: Reduces aggregate requirements by 30-40%

Installation Advantages: Lighter weight than traditional composites

Quality Assurance: Factory-direct production with complete quality control

Available Configurations:

Standard rolls: 2-8m width × 50-100m length

Custom sizes and material combinations available

Special formulations for chemical resistance

Textured surface options for slope applications

Certifications & Standards:

ASTM D7176 (Composite Geomembranes)

GRI-GM13 (Geomembrane Specifications)

ISO 9001:2015 Quality Management

CE Marking for European markets

Packaging & Delivery:

Protective wrapping on steel or wooden cores

Weatherproof packaging for ocean transport

20-25 rolls per 40HQ container

15-30 days lead time (standard orders)

Company’s Strength:

Established in 2008, Haoyang Environmental Technology Co., Ltd. is a leading manufacturer of high-performance geosynthetic products, specializing in composite geomembranes, geotextiles, and drainage solutions. With our 35,000㎡ production base in Shandong, China, we serve global clients in environmental, water conservancy, mining, and civil engineering projects.

![Nonwoven Geotextile Composite Geomembrane Nonwoven Geotextile Composite Geomembrane]()

![Nonwoven Geotextile Composite Geomembrane Nonwoven Geotextile Composite Geomembrane]()