Introduction

A quality 8 oz non-woven geotextile fabric is a cost-effective solution that enhances the durability, functionality, and appearance of gravel surfaces. By investing in the right fabric and installing it correctly, you’ll save time and money on future maintenance while enjoying a more reliable and attractive driveway or path.

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

Applications

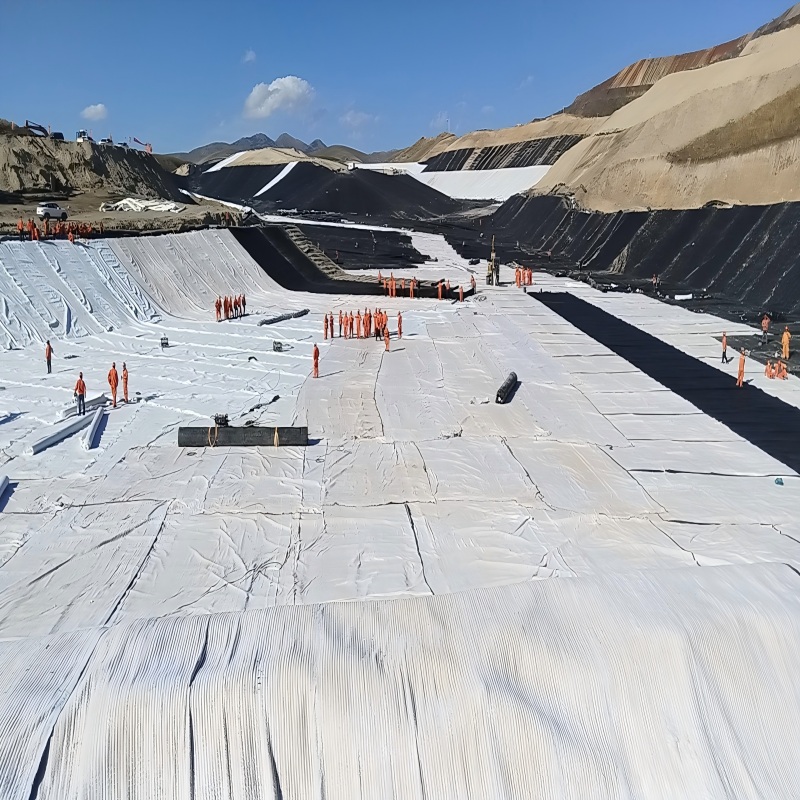

This 8 oz non-woven geotextile is suitable for:

Gravel driveways and parking areas

Walkways and garden paths

Patio and retaining wall bases

French drains and subsurface drainage systems

Erosion control on slopes

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

Purchasing & Usage Tips

1. Confirm the weight: When purchasing, always confirm that the packaging states 8 oz per square yard (oz/yd²).

2. Choose a "non-woven" type: For driveway applications, non-woven geotextiles are preferred. They are more like felt, providing excellent filtration and separation properties, and are highly flexible, allowing them to better adapt to irregular subgrade shapes.

Proper Installation

Clean the ground, level it as much as possible, and compact the subgrade.

Lay the geotextile, ensuring an overlap (12-18 inches is generally recommended).

Geotextile staples can be used to secure the geotextile to prevent movement.

After laying, cover with gravel immediately to protect the geotextile from prolonged UV exposure, which can degrade it.

Why Use Geotextiles on Gravel Driveways?

1. It prevents the soil and gravel from mixing. If there's soft mud underneath and gravel on top, without this layer of cloth separating them, the gravel would sink into the soil after repeated wheel movement. Over time, the road becomes riddled with potholes, requiring repeated additions of new gravel. With geotextiles, the top and bottom layers are completely separated, ensuring the gravel layer maintains a uniform thickness and resists deformation.

2. It distributes pressure. The geotextile spreads the force of the wheels, significantly reducing the burden on the underlying soil. This results in a more stable and robust driveway, making it particularly suitable for soft soils.

3. It is water-permeable without soil leakage. It allows water to drain away smoothly, preventing the foundation from being softened, while also retaining soil from seeping in. This improved drainage naturally extends the life of the driveway.

About Us

As an experienced manufacturer of geosynthetic materials, Haoyang Environmental Technology provides high-performance 8 oz geotextile fabric specifically engineered for gravel driveway applications. Our nonwoven polypropylene geotextile delivers optimal separation, filtration, and stabilization for residential, commercial, and agricultural driveway projects.

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()

![8 OZ Nonwoven Geotextile Fabric for Gravel Driveway 8 OZ Nonwoven Geotextile Fabric for Gravel Driveway]()