Introduction

Nonwoven geotextile is a geosynthetic material which is main made with directly forming to net and consolidating fibers without traditional textile processes such as weaving or knitting. It is mainly divided into short-fiber needle-punched geotextile or filament spunbond needle-punched geotextile. Among them, filament spunbond needle-punched geotextile is a high-performance nonwoven geotextile. It is made of polyester filament non-raw materials, spunbonded into a net and needle-punched reinforcement process. It has the advantages of high strength, good drainage, long durability, etc., so it is widely used in civil engineering fields with high requirements.

![Non Woven Geotextile Non Woven Geotextile]()

Production process and flow

Step1-Spinning: After the polyester melt is extruded through the spinneret, it forms continuous filaments.

Step2-Web laying: The filaments are randomly laid into a fiber web by airflow or mechanical means (spunbond method).

Step3-Needle punching reinforcement: Use a barbed needle to repeatedly pierce the fiber web to make the fibers entangled with each other to form a stable structure.

Step4-Post-treatment (optional): Heat setting and anti-UV treatment to improve dimensional stability and enhance weather resistance to adapt to long-term exposure environment.

Key Performance

Performance | Characteristics | Advantages |

High Strength | High longitudinal and transverse tensile strength, up to more than 30kN/m | Suitable for high-load projects, such as high-speed rail and airport runways |

Tear resistance | Needle punching process enhances fiber entanglement,excellent tear resistance | Resistant to mechanical damage during construction or use |

Water permeability and filterability | Three-dimensional pore structure, large ility coefficient (10⁻¹~10⁻³ cm/s) | Effective drainage and prevention of soil loss |

Chemical corrosion resistance | Acid and alkali resistance, microbial erosion resistance | Suitable for landfills and chemical parks |

UV aging resistance | Add anti-UV agents to extend ourdoor service life | Suitable for long-term exposed slope protection and dams |

Applications

1. Transportation:

High-speed rail ballastless track: used as an isolation layer for the track.

Airport runway: reinforce the base to prevent uneven settlement.

Expressway: used as soft foundation treatment to improve the stability of the roadbed.

2. Water conservancy projects:

Slope protection and anti-scouring: combined with gabions or concrete blocks to enhance the ability to resist water erosion.

Drainage and anti-filtration: used in the waterproof system of the dam to prevent pipe bursts.

3. Environmental protection projects:

Landfill: as a protective layer of the lining system, isolating the anti-seepage membrane and sharp objects.

Tailing pond management: prevent the migration of tailings particles and take into account the drainage function.

4. Municipal engineering

Underground official website protection: wrap the drainage pipe to prevent silt clogging.

Sponge city: used as a filter layer under the permeable pavement.

![Non Woven Geotextile Geotech Fabric Non Woven Geotextile Geotech Fabric]()

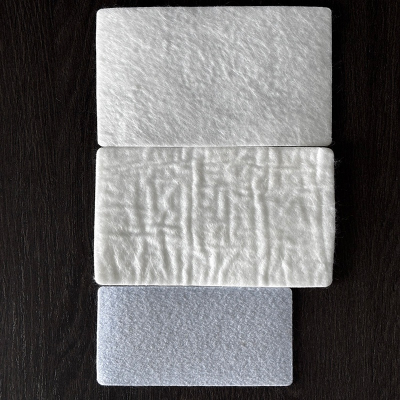

Comparison with Staple Needle-punched Geotextile

Parameter | Filament Spunbond Needle-punched Geotextile | Staple Needle-punched Geotextile |

Raw Materials | PET continuous filament | PET/PP Staple Fiber |

Strength | Higher, longitudinal/lateral uniformity | Medium |

Uniformity | More uniform fiber distribution | Possible local weak points |

Cost | Higher | Lower |

Application | High loads or harsh environments | Filtration or isolation |

Construction points

1. Laying direction: The high-strength direction should be aligned with the main stress direction.

2. Overlap treatment: Overlap width ≥ 30cm, heavy engineering requires stitching or thermal bonding.

3. Protection measures: Avoid direct rolling or exposure to ultraviolet rays, and cover the filler in time.

4. Quality inspection: On-site sampling of thickness, gram weight, breaking strength and other indicators.

Selection of Different Weight

1. 100-200g/㎡

Application: light-duty engineer, temporary protection, basic filtration

Features: low cost, convenient construction, low tensile strength (longitudinal 10-15kN/m)

2. 200-400g/㎡

Application: highways, municipal engineer, water conservancy projects

Features: balanced strength (longitudinal 20-30kN/m) and water permeability, high cost performance

3. 400-600g/㎡

Application: heavy-duty transportation, water conservancy hubs, landfills

Features: high strength (longitudinal 30-50kN/m), wear resistance, suitable for long-term load

4. 600-1000g/㎡ and above

Application: high-speed rail, deep-sea reclamation, extreme environment engineering

Features: ultra-high strength (longitudinal ≥50kN/m), anti-UV aging, high cost

Selection considerations

1. Load requirements: For large projects such as airports and high-speed railways, high-weight products of ≥400g/㎡ need to be selected.

2. Water permeability requirements: Drainage projects are best to choose medium-to-low weight products with larger pores (200-400g/㎡).

3. Environmental corrosiveness: Corrosive environments such as landfills and chemical parks need to be used with chemical corrosion resistant layers.

4. Cost control: Non-critical parts in projects such as temporary roads can use low weight products to save budget.

Packaging and Transportation

Weight(g/㎡) | Single Roll Weight(kg) | 20GP | 40HQ |

100-200 | 80-120kg | 80-100 rolls | 160-200 rolls |

200-400 | 150-300kg | 50-70 rolls | 100-140 rolls |

400-600 | 350-500kg | 30-40 rolls | 60-80 rolls |

600-800 | 550-700kg | 20-30 rolls | 40-60 rolls |

800-1000+ | 750kg+ | 15-20 rolls | 30-40 rolls |

1. The calculation basis in 5m in width, 1m in diameter, and 50-100m in length. The higher the weight, the longer the single roll.

2. If the roll diameter is greater than 1.2m, the number of stacked layers needs to be reduced. If the weight exceeds 800g/㎡, a single layer is recommended.

3. Packaging: moisture-proof PE film and woven cloth. The volume will increase by about 5%.

![Non Woven Geotextile Geotech Fabric Non Woven Geotextile Geotech Fabric]()

Company’s Strength

Haoyang Environmental is a leading enterprise focusing on the research and development, production and global supply of geotextiles, committed to providing high-quality geosynthetics solutions for infrastructure construction, environmental engineering and water conservancy projects. With 20 years of industry experience and technological innovation, we have become a core supplier of many large-scale engineering projects at home and abroad, and our products are exported to Brazil, Peru, Indonesia and other countries and regions.

![Non Woven Geotextile Geotech Fabric Non Woven Geotextile Geotech Fabric]()