Introduction

LLDPE geomembrane made of linear low-density polyethylene(LLDPE) is a geosynthetic material . It has stronger tensile strength, puncture resistance and flexibility than low-density polyethylene, which is a ideal choice engineering such as anti-seepage, isolation, and protection.

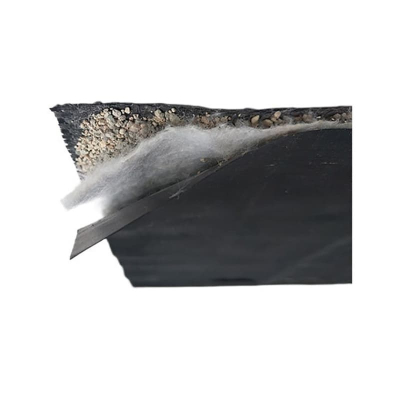

![LLDPE Geomembrane Dam Liners 1.5 mm LLDPE Geomembrane Dam Liners 1.5 mm]()

Main Features

1. Impermeability: effectively prevent liquid or gas penetration due to its low permeability.

2. Chemical corrosion resistance: suitable for complex environments due to its resistance from chemical corrosion such as acids, alkalis, salts and greases.

3. Strong flexibility: adapts to foundation deformation and not easy to crack.

4. Puncture resistance: suitable for laying on complex base surfaces with sharp objects (such as landfills).

5. Convenient construction: it can be formed into a continuous whole by welding or bonding.

Application

1. Environmental protection: anti-seepage layer of landfills, pools, and hazardous waste storage.

2. Water conservancy: anti-seepage of reservoirs, channels, and artificial lakes.

3. Agriculture: anti-seepage of reservoirs and biogas pools.

4. Mining: anti-pollution isolation of tailings ponds and heap leaching pools.

5. Transportation: moisture-proof isolation layer of highway and railway roadbeds.

![LLDPE Geomembrane Dam Liners 1.5 mm LLDPE Geomembrane Dam Liners 1.5 mm]()

![LLDPE Geomembrane Dam Liners 1.5 mm LLDPE Geomembrane Dam Liners 1.5 mm]()

Technical Parameters

1. Physical and Mechanical Properties

Parameter | Scope | Test Standards |

Thickness | 0.2mm - 2.0mm | ASTM D5199 |

Density | 0.915 - 0.935 g/cm³ | ASTM D1505 |

Tensile Strength | Vertical | ≥20 MPa | ASTM D6693 |

Horizontal | ≥20 MPa | ASTM D6693 |

Elongation at break | Vertical | ≥500% | ASTM D6693 |

Horizontal | ≥500% | ASTM D6693 |

Right Angle Tear Strength | ≥80 N/mm | ASTM D1004 |

Puncture Resistance | ≥300 N | ASTM D4833 |

Yield Strength | ≥10 MPa | ASTM D6693 |

2. Impermeability abd Durability

Parameter | Scope | Test Standards |

Permeability Coefficient | ≤1×10⁻¹³ m/s | ASTM E96 |

Hydrostatic Pressure Resistance | ≥0.6 MPa | GB/T 17391 |

Anti-ultraviolet Aging | ≥80% after 1500h | ASTM G154 |

Oxidation Induction Time | ≥100 min | ASTM D3895 |

3. Chemical and Environmental Adaptability

Parameter | Require |

Chemical Resistance | Acid and alkali resistant (pH 2~12), salt, organic solvents (specific testing required) |

Operating Temperature Range | -60°C - +60°C |

Environmental Stress Cracking | ≥1500 hrs (ASTM D5397) |

4. Other Parameters

Carbon black content: 2%~3% (for UV resistance, ASTM D4218).

Surface texture: smooth/rough (rough surface has higher friction coefficient, suitable for slopes).

Weld strength: ≥80% of the parent material strength (ASTM D6392).

Why Choose LLDPE Geomembrane?

1. LLDPE geomembrane has high flexibility and strong deformation adaptability, which is usually softer than HDPE geomembrane. It is suitable for complex terrains due to its elongation at break can reach 800%.

2. The impact resistance and stress cracking resistance of LLDPE geomembrane are better than HDPE geomembrane, and it can prevent puncture by sharp objects.

3. The low-temperature brittleness temperature of LLDPE geomembrane can be as low as -70°C,which can keep high flexibility in winter or cold areas, as well as can effectively prevent frost heave cracking.

4. It is resistant to acid and alkali, salt, and some organic solvents due tu its high chemical stability. It can be used in acid, alkali, and salt spray corrosion environments such as chemical industry and seawater aquaculture.

5. The welding temperature of LLDPE geomembrane is lower than HDPE geomembrane, which is easier to hot-melt weld, and the weld strength is high. It can be used in emergency projects or heterogeneous structures.

About Us

Haoyang Environmental is a company focusing on the research and development, aiming to product and construct high-performance geosynthetics. Providing reliable anti-seepage, isolation and protection solutions for environmental protection, water conservancy, mining, municipal administration and agriculture is our commission.

Company's products mainly include geomembrane, composite geomembrane, geotextile, geogrid, geocell and others, which are widely used in landfills, pools, tailings ponds, artificial lakes, agricultural, reservoirs and other projects. We strictly follow the ISO 9001 and our products comply with international and domestic standards such as GB/T, ASTM, GRI to ensure anti-seepage, anti-aging and environmental adaptability.

With advanced extrusion production lines, rigid process control and professional construction teams, we provide customers with one-stop services from material customization, technical consultation to on-site installation to ensure project quality and long-term stability.

![LLDPE Geomembrane Dam Liners 1.5 mm LLDPE Geomembrane Dam Liners 1.5 mm]()

![LLDPE Geomembrane Dam Liners 1.5 mm LLDPE Geomembrane Dam Liners 1.5 mm]()