Introduction

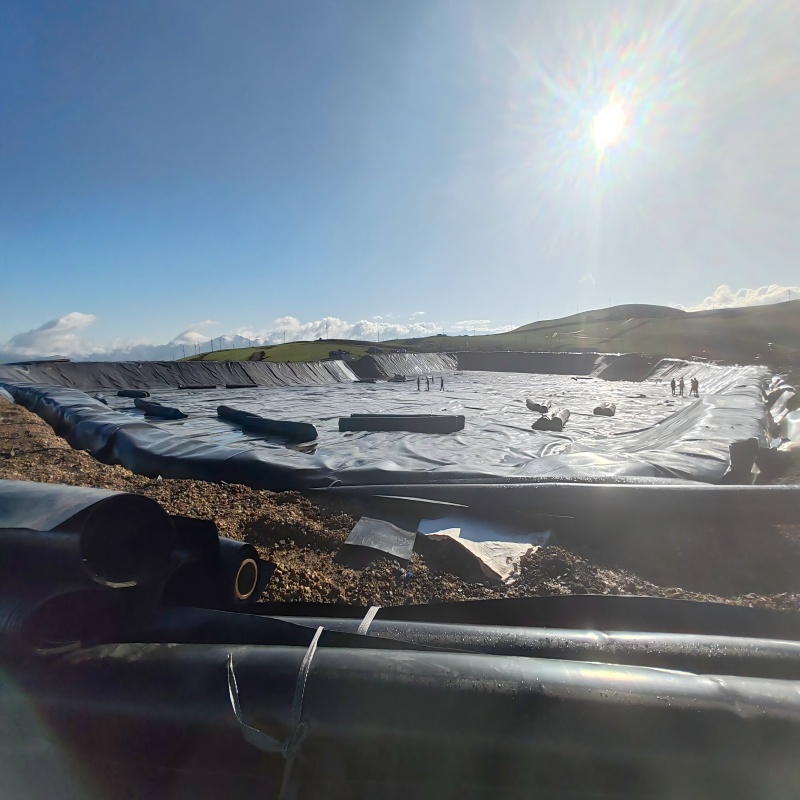

HDPE Geomembrane Sheet for Mining is a high-performance synthetic anti-seepage material widely used in civil engineering, environmental engineering and water resources management. It is made of high-density polyethylene (HDPE) resin as the main raw material and is made into a continuous, uniformly thick sheet film through processes such as extrusion, calendering or blow molding. In the mining field, it is the core barrier of the anti-seepage system of tailing ponds and heap leaching pads, and is often called mining heap leach pad liner or tailing pond liner.

![HDPE Geomembrane Sheet for Mining HDPE Geomembrane Sheet for Mining]()

Key Features

1. Excellent Impermeability:

It has extremely low water vapor permeability coefficient and liquid permeability, and can effectively block water, chemical solutions, gases and pollutants.

In heap leach pads, as mining heap leach pad liner, it can effectively prevent precious metal leachate containing cyanide, strong acid (such as sulfuric acid) or other leaching agents from seeping into the ground and polluting soil and groundwater. In tailing ponds, it can effectively prevent the leakage of tailings slurry leachate containing heavy metals, mineral processing agents and fine solid particles.

2. Excellent Chemical Stability:

It has strong corrosion resistance to most acids, alkalis, salts, oils and organic solvents. This is the key reason why HDPE geomembrane is irreplaceable in heap leaching fields and tailings ponds. It can withstand the erosion of highly corrosive leachate in heap leaching fields (such as dilute sulfuric acid heap leaching copper ore, cyanide heap leaching gold ore) and tailings leachate with complex chemical components in tailings ponds for a long time.

3. High Mechanical Strength and Durability:

With good tensile strength, tear strength, puncture strength and creep resistance, it can withstand construction stress, foundation settlement, cover load and potential threats from sharp objects. Excellent weather resistance and UV resistance ensure long-term service, up to 50 years or more.

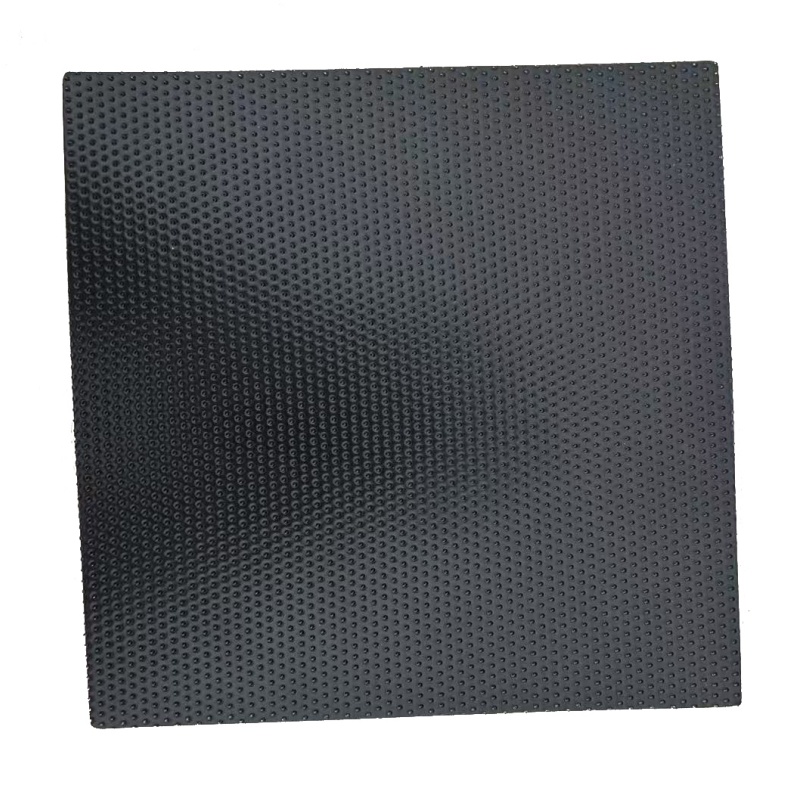

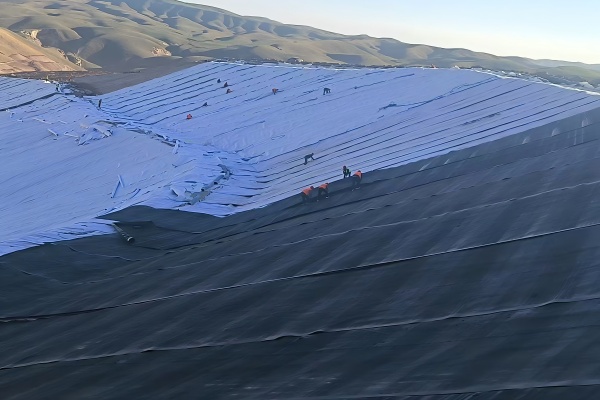

The slope of the tailings dam and the steep slope of the leaching field require extremely high material strength to prevent tearing and sliding. HDPE Textured Geomembrane is particularly important in such applications. Its surface texture (single or double rough) significantly increases the friction coefficient with the underlying geotextile, geonet or upper cover material (such as soil, gravel), greatly improving the stability of the slope and preventing the liner system from sliding and failing on steep slopes. Geomembrane Suppliers usually recommends rough membranes with specific texture types (such as spraying, embossing) and friction properties for mining projects.

4. Weldability and quality control:

Through professional welding technologies such as hot wedge welding and extrusion welding, the joints are firmly connected to ensure the integrity of the overall anti-seepage system.

Welding quality is the lifeline of mining anti-seepage projects. In order to detect the quality of welds more intuitively and reliably, mining projects are increasingly using Dual Color HDPE Geomembrane. This product produced by a professional Two-Color Geomembrane Manufacturer uses two contrasting colors (such as black/white, green/black) on the upper and lower surfaces or the membrane itself. When welding:

Hot wedge welding: After the welder moves, the molten weld will cover the color of the lower membrane, forming a clear, high-contrast weld, which is convenient for visual inspection of weld continuity and width uniformity.

Extrusion welding: The extruded molten electrode will fuse with the lower membrane, and the color contrast makes the electrode filling and fusion status clear at a glance.

Advantages: Greatly reduce the risk of missed detection, improve the efficiency and reliability of weld detection, and are particularly suitable for large and complex mining lining projects. It is crucial to select experienced Geomembrane Suppliers and Welding Contractors.

Core Application Scenarios in Mining

1. Heap Leach Pads: Mining heap leach pad liner.

Function: Lay under the ore pile to form a huge "impermeable basin" to collect the leach solution (Pregnant Leach Solution - PLS) rich in target metals (such as gold, silver, copper, uranium), and safely divert it to the collection pool, while absolutely preventing highly corrosive, toxic leachants and dissolved heavy metals from infiltrating the foundation.

Material Selection: Usually thicker (1.5mm - 2.5mm+) HDPE geomembranes are used. HDPE Textured Geomembrane (mostly double rough surface) is strongly recommended for slopes to provide sufficient friction to resist the ore pile load and slope stability requirements. The welding quality requirements are extremely high, and the application of Dual Color HDPE Geomembrane has significant advantages in this scenario.

2. Tailing Ponds: As foundation lining and/or slope lining.

Function: To store tailings slurry (water + fine solids + residual chemicals + possible heavy metals) generated during the beneficiation process. The lining system must ensure that these harmful substances do not leak and protect the surrounding environment and groundwater safety. At the same time, it is also used for leachate storage ponds in heap leaching processes (PLS Pond, Barren Pond).

Material selection: It is one of the areas with the largest consumption and most stringent requirements of HDPE geomembrane. Smooth or single rough surface membranes (rough surface facing up and in contact with the protective layer/drainage layer) are commonly used in the foundation. HDPE Textured Geomembrane (usually double rough surface) must be used for slopes (especially steep dam body slopes) to provide maximum interface friction resistance and ensure the coordinated stability of the lining system and the dam body geotechnical materials (geotextile, geonet, clay). The thickness is usually 1.5mm - 2.0mm+. Dual Color HDPE Geomembrane is also recommended to improve the quality control level of welding. Reliable Geomembrane Suppliers need to provide products that meet strict mining regulations.

HDPE Geomembrane Sheet for Mining Core Physical Parameter Range

Parameters | Standard Range | Key Requirements for Mining |

Thickness | 1.5 - 3.0 mm | Heap leach pad ≥2.0mm; tailings pond slope ≥2.0mm |

Carbon Black Content & Dispersion | 2.0–3.0 % / ≤Grade 2 | Uniform UV resistance, no agglomeration (ASTM D5596) |

Tensile Strength | ≥25 kN/m (vertical/lateral) | For steep slopes/high load areas, BIDIM (≥50) or high-strength rough mask are preferred. |

Mechanical Damage Resistance | Puncture ≥500 N Tear ≥150 N | Heap leaching site ore area: Puncture ≥600N; Tailings pond foundation: Tear ≥200N (ASTM D4833/D1004) |

Elongation at Break | ≥600 % | -70°C Low temperature environment ≥300% (suitable for high-cold mining areas) |

Interface Friction Angle | Rough film ≥30° | When the tailings pond slope is >1:3, a double rough film must be used (ASTM D5321) |

Stress Cracking Resistance | ≥1500 hrs | Mandatory requirement for strong acid/cyanide environments (such as heap leaching liquid) (ASTM D5397) |

Permeability Coefficient | <10⁻¹³ cm/s | Need to cooperate with two-color film weld inspection to ensure overall sealing |

Low-temperature Embrittlement Temperature | ≤-70 °C | Required in cold areas (such as Mongolia and Canadian mining areas) (ASTM D746) |

Selection Recommendations

1. Prioritize professional Geomembrane Suppliers: Require third-party test reports (such as GRI-GM13, ASTM standards).

2. Key parts of mining: Specify BIDIM (biaxially oriented HDPE) or high-strength rough surface HDPE membrane.

3. Welding quality control: Use Dual Color HDPE Geomembrane and cooperate with electric spark/vacuum detection.

Selection and Construction Points (Special Emphasis for Mining Projects)

1. Thickness and Strength: Mining projects usually require thicker specifications (≥1.5mm, ≥2.0mm in key areas) to meet high load, puncture resistance and long-term durability requirements.

2. Surface Type: HDPE Textured Geomembrane is the standard for tailings pond slopes and heap leaching field slopes. The selection of texture type (spray roughening, embossing) and friction coefficient needs to be determined according to specific design calculations.

3. Raw Materials and Carbon Black: High-quality virgin HDPE resin must be used, with a carbon black content of ≥2% and uniform distribution to ensure long-term UV resistance.

4. Welding Quality Control: It is the key to the success or failure of mining projects. It is strongly recommended to use Dual Color HDPE Geomembrane, in conjunction with strict welding procedures (PQS), welder qualification certification, and comprehensive non-destructive testing (spark, vacuum box, air pressure/vacuum chamber, and destructive testing).

5. Supplier selection: It is important to select experienced and reputable Geomembrane Suppliers who can provide complete quality documents (raw material certificates, production records, third-party test reports) and technical support. For two-color membranes, a professional Two-Color Geomembrane Manufacturer with successful mining project cases should be selected.

6. Protective layer: Carefully design and lay the geotextile protective layer and the appropriate soil and stone cover layer (without sharp edges) to prevent mechanical damage during construction and service.

Haoyang’s HDPE Geomembrane Sheet for Mining Industry

HDPE Geomembrane Sheet, especially HDPE Textured Geomembrane and Dual Color HDPE Geomembrane, is the cornerstone material for modern mining environmental protection. As reliable mining heap leach pad liner and tailings pond liner, they provide indispensable anti-seepage protection for heap leach pads and tailings ponds, effectively preventing toxic and harmful solutions from polluting the environment. Its excellent chemical stability, high strength, durability and excellent slope stability achieved through rough surface design make it the first choice for mining projects. When choosing, be sure to cooperate with professional Geomembrane Suppliers. For key quality control links (such as welding), give priority to two-color film products produced by professional Two-Color Geomembrane Manufacturers, and implement the highest standards of construction and acceptance specifications.

![HDPE Geomembrane Sheet for Mining HDPE Geomembrane Sheet for Mining]() | ![HDPE Geomembrane Sheet for Mining HDPE Geomembrane Sheet for Mining]() |

Haoyang Environmental Technology ( Shandong ) Co., Ltd. stands as China's specialized geomembrane supplier for aggressive mining applications since 2008 our textured HDPE geomembranes with 1.5mm dual color construction provide visual installation quality control while the 3D surface profile achieves 35 degree static friction angles critical for heap leach pad liner stability manufactured from prime grade polyethylene with 2.5 carbon black dispersion these sheets deliver 0 03 perm permeability and 6000 N puncture resistance exceeding ASTM GM13 standards for acid rock drainage containment proven in global copper gold and lithium operations including Peru's 1200 hectare leach pads and Chilean high altitude mines where our two-color geomembrane systems reduced leakage inspection costs by 70 through instant defect identification as certified mining heap leach pad liner manufacturers we offer 10 meter wide seamless rolls with robotic welding protocols ensuring 100 seam integrity even in minus 40C environments request ore abrasion test reports validating 50 year service life under sulfide exposure.

![HDPE Geomembrane Sheet for Mining HDPE Geomembrane Sheet for Mining]() | ![HDPE Geomembrane Sheet for Mining HDPE Geomembrane Sheet for Mining]() |

Q&A: Shipping, Factory & Product Information

Q: What are your shipping methods and timelines?

A: We partner with major carriers (DHL, FedEx, UPS) for express shipping and offer ocean freight for bulk orders. You can also use your preferred freight forwarder. Costs vary by weight, size, destination, and method; contact us for a quote. Delivery typically takes 3-15 business days for express and 20-45+ days for ocean freight.

Q: Where is your factory located?

A: Our factory is situated in Dezhou City, Shandong Province, conveniently close to Jinan (the provincial capital) with excellent transportation links. We welcome visits! Please see our company details for the exact address.

Q: Do you offer product warranties?

A: Yes. All products come with a standard 12-month warranty covering manufacturing defects. Specific warranty terms are in the product description, or you can contact us for details.

Q: Can I order samples before a bulk purchase?

A: Absolutely. We strongly recommend sampling to verify quality, specifications, and suitability for your environment. Contact our sales team for sample pricing and shipping costs.