Introduction

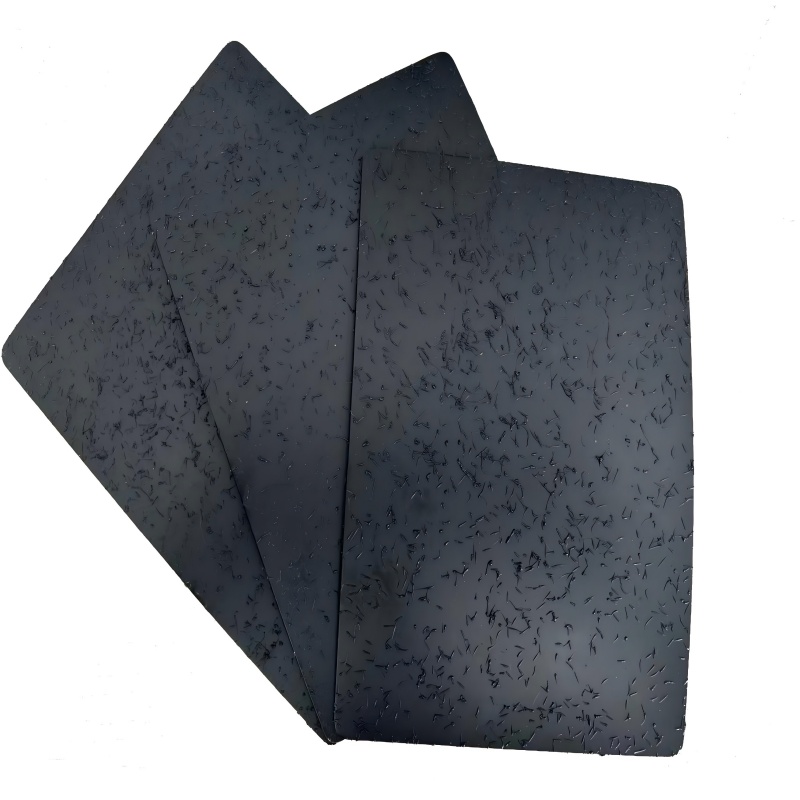

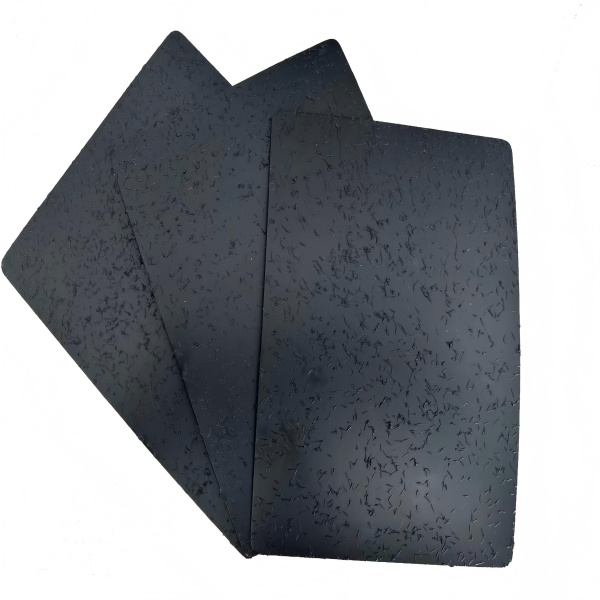

60 mil HDPE Textured Geomembrane is the gold popular for present day landfill waterproofing systems, offering an all-around overall performance enchancment over traditional sleek videos or thinner merchandise such as 30 Mil Geomembrane Liner.

Key Advantages

Excellent anti-slip properties: The coefficient of friction reaches 0.6-0.8, twice that of clean membranes, making it in particular appropriate for slope engineering.

Dual drainage: The special concave-convex shape concurrently achieves: Leachate drainage (reducing hydrostatic pressure), methane gasoline series (reducing the chance of methane explosions)

Welding reliability: The textured floor will increase weld power by way of 30%.

Material Composition and Manufacturing

The HDPE Textured Geomembrane is manufactured from high-grade polyethylene resin with specialized additives:

Carbon black (2-3%) for UV stabilization

Antioxidants to prevent oxidative degradation

Stabilizers for temperature resistance

The texturing process creates a uniform surface pattern with:

Peak-to-valley top of 0.3-0.8mm

Surface roughness (Ra) of 20-50μm

Pattern density of 40-60 peaks per rectangular inch

Application

Hazardous waste landfills: Withstands extreme pH environments of 2-12

Mine tailings ponds: Resists punctures from sharp objects in the ore

Methane collection systems: Textured surface facing downward optimizes gas conduction

Steep slopes: 3:1 slopes require no additional anchoring

Comparison between Smooth & Textured Liner

Specifications | 60mil (1.5mm)Textured Film | 40mil (1.0mm) Smooth Film | Test Standards |

Tensile Strength | 28-35MPa | 20-25MPa | ASTM D6693 |

Elongation at Break | 700-900% | 500-700% | ASTM D6693 |

Puncture Resistance | 400-500N | 250-300N | ASTM D4833 |

Service Life | 50+ Years | 25-30 Years | Field Data |

![1755135877708369.jpg 1(2).jpg]() | ![1755135885808874.jpg 光(1).jpg]() |

| Textured | Smooth |

Performance Parameters

Feature | Smooth Liner | Textured Liner |

Friction | Low (slippery) | High (anti-slip) |

Drainage | Poor | Better gas/fluid flow |

Installation | Easier to weld | Requires skilled welding |

Cost | Lower | Slightly higher |

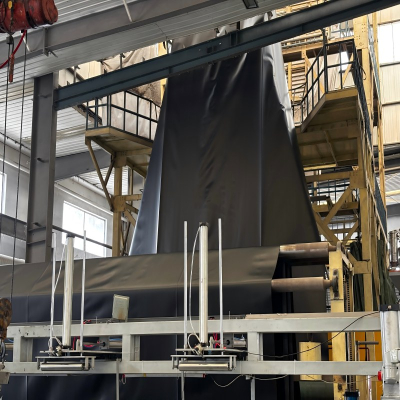

About Us

As an enterprise chief in geosynthetic containment systems, Haoyang Environmental Technology manufactures top rate 60 mil landfill liner with texture, engineered for most overall performance in current waste administration facilities. Our heavy-duty textured HDPE geomembrane elements a in particular designed 3D floor sample that enhances interface friction (up to 35° static friction angle) whilst retaining outstanding hydraulic integrity (0.03 perm vapor barrier rating).