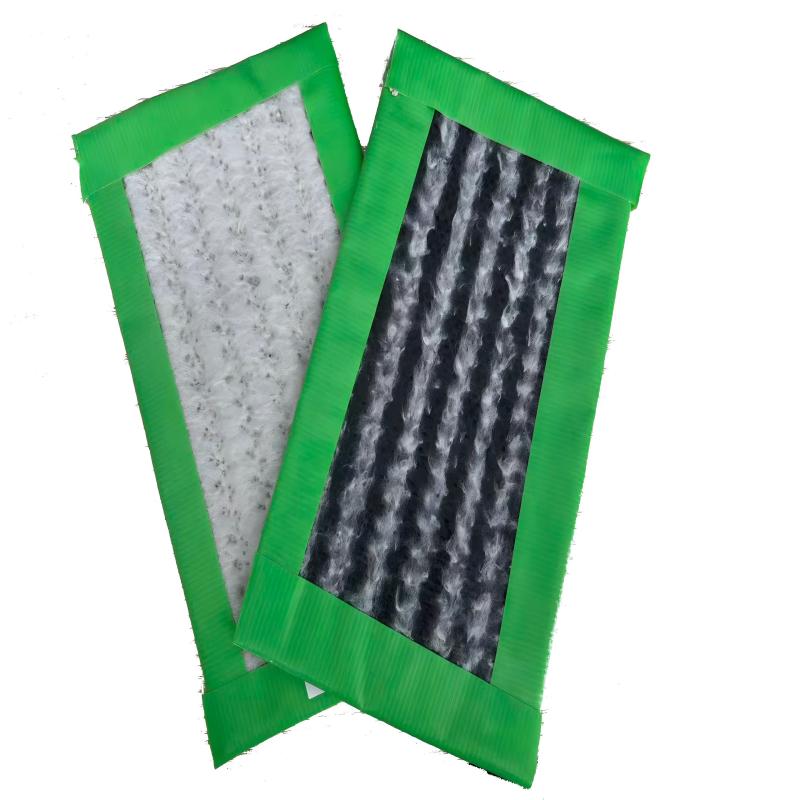

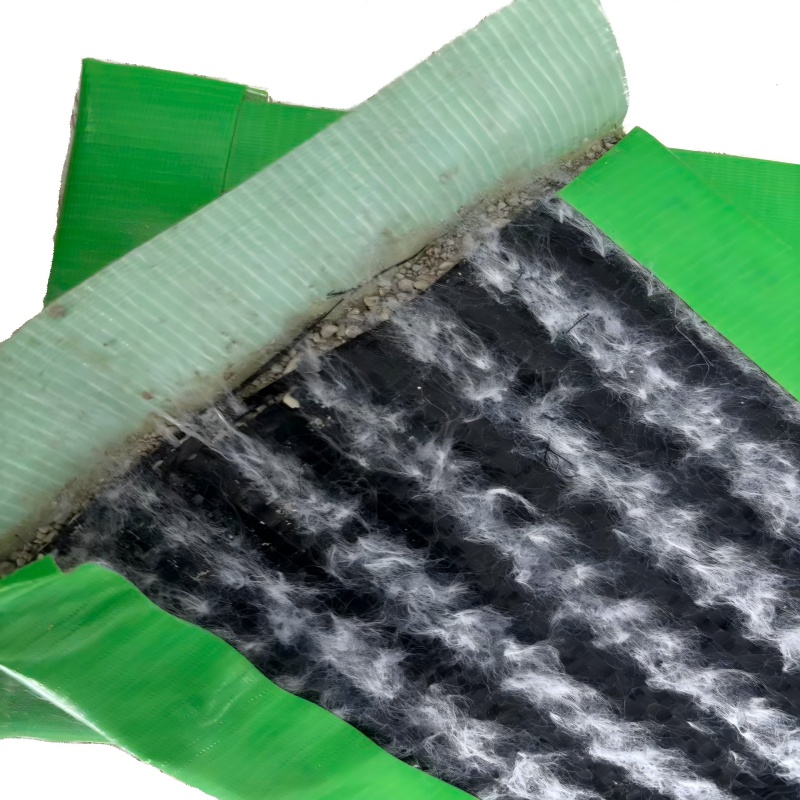

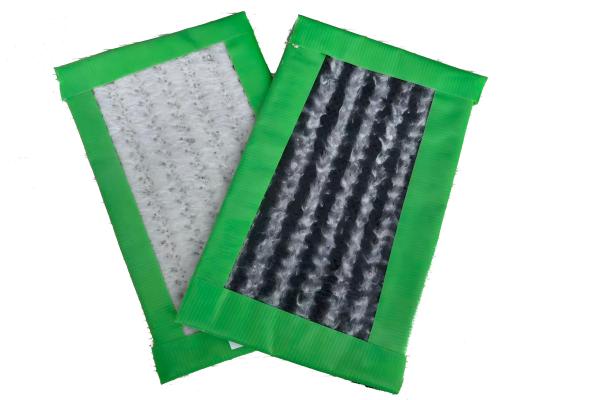

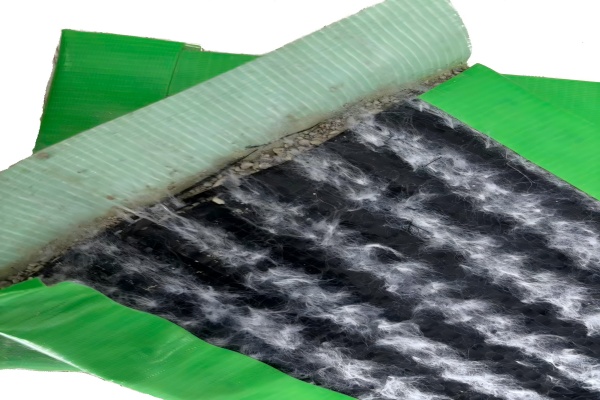

1. Extremely low permeability (≤10⁻⁹ cm/s): Bentonite expands upon contact with water, forming a dense colloid that is without a doubt impermeable, supplying gold standard seepage manage overall performance in contrast to compacted clay (10⁻⁷-10⁻⁸ cm/s). Suitable for landfill liners with stringent environmental requirements.

2. Lightweight & skinny format (5mm-10mm thickness): Bentonite liners are 5mm/10mm thick, appreciably thinner than standard compacted clay layers (≥600mm), saving landfill space. The lightweight format approves for environment friendly transportation and installation, decreasing building costs.

3. Freeze-thaw & wet-dry cycle resistance: Highly adaptable to environmental conditions, keeping impermeability even below repeated wet-dry cycles, whereas compacted clay is susceptible to cracking.