Introcution

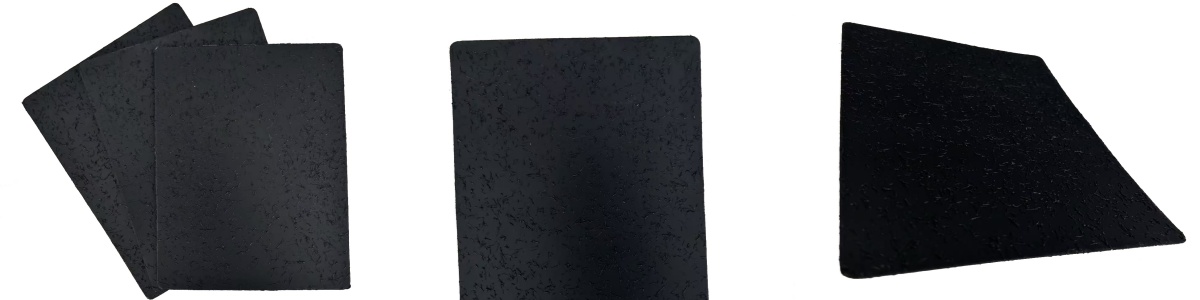

Nitrogen-sprayed double-roughened geomembrane is a HDPE anti-seepage material made by nitrogen roughening technology. It has high friction, strong anti-seepage, corrosion resistance and long life, and is suitable for scenes with high requirements for engineering stability and environmental protection. With its high friction coefficient, excellent anti-seepage performance, convenient construction and environmental protection characteristics, it has become an indispensable material in modern engineering. Its technological advantages have gradually replaced traditional roughened geomembranes and become a key material in modern geotechnical engineering. Its production process is more efficient and durable, and it is suitable for all kinds of harsh engineering environments.

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()

Product application

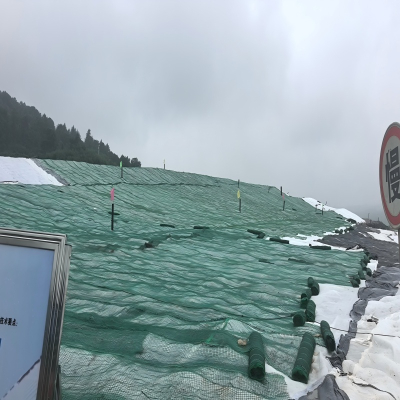

1. Landfill: Prevent leachate from polluting groundwater and improve slope stability

2. Water conservancy projects: Used for reservoir and channel anti-seepage, and enhance the anti-slip ability of dam bodies

3. Mine restoration: Prevent the spread of heavy metal pollution and improve the stability of slope covering

4. Chemical anti-seepage: Used for chemical sewage pools and oil storage tank foundation anti-seepage, with strong corrosion resistance

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()

Features

1.Use unique nitrogen spraying process to enhance surface texture, form high friction non-slip surface on both sides, improve stability in slope and landfill applications.

2.Excellent interfacial shear strength, suitable for soil-geomembrane and geotextile-geomembrane interface, reduce the risk of slip.

3.The raw materials adopt high-performance high-density polyethylene material and carbon black formula, with excellent UV resistance and chemical resistance.

4.Extremely low permeability, ensuring fluid control performance in ponds, landfills and mining industries.

5.Customizable according to engineering needs.

Parameter Technicals

1. Physical and Mechanical Properties

Parameter | Typical Value | Test Standard | Description |

Thickness (mm) | 0.75-3.0 | GB/T 6672 | Commonly used 1.0mm, 1.5mm, 2.0mm |

Density (g/cm³) | ≥ 0.94 | GB/T 1033 | High-density polyethylene (HDPE) |

Tensile Strength (Longitudinal/transverse, Mpa) | ≥ 25/ ≥ 25 | GB/T 1040.3 | - |

Elongation at Break (%) | ≥ 700 | GB/T 1040.3 | Adapt to foundation deformation |

Right-angle Tear Strength (N/mm) | ≥ 110 | GB/T 1130 | Tear-resistance |

Puncture Resistance (N) | ≥ 400 | ASTM D4833 | Resistant to stone debris and tree root penetration |

CBR Bursting Strength (kN) | ≥ 2.5 | GB/T 14800 | Resistant to local loads |

2. Anti-seepage Performance

Parameter | Typical Value | Test Standard | Description |

Permeability (cm/s) | ≤1×10⁻¹³ | GB/T 17642 | Low water permeability |

Water Vapor Transmission Rate (g·m⁻²·d⁻¹) | ≤0.1 | ASTM E96 | Moisture resistance |

Hydrostatic Pressure Resistance (MPa) | ≥0.6 | GB/T 17391 | Water pressure resistance |

3. Friction Performance

Parameter | Typical Value | Test Standard | Description |

Friction Coefficient | 0.6 - 1.2 | ASTM D5321 | Anti-slip ability |

Roughness height (μm) | 100 - 500 | Laser Profiler | Influence on friction coefficient |

Interface Shear Strength (kPa) | ≥30 | ASTM D6243 | Slope stability |

4. Environmental Resistance

Parameter | Typical Value | Test Standard | Description |

Acid and Alkali Resistance (pH 2-12) | No significant change | GB/T 17642 | Chemical corrosion resistance |

UV Resistance | 5000h strength retention rate ≥80% | GB/T 16422.3 | Outdoor long-term use |

Low Temperature Brittleness Temperature (°C) | ≤-70 | GB/T 5470 | Cold resistance |

Oxidation Induction Time (OIM, min) | ≥100 | ASTM D3895 | Antioxidant ability |

5. Construction-related Parameters

Parameter | Typical Value | Description |

Width (m) | 3-8m | Reduce joints and improve construction efficiency |

Roll Length (m) | 50-300m | Adapt to different project requirements |

Welding Temperature (°C) | 250 - 350 | Applicable to hot melt welding |

Overlap Width (cm) | ≥10 | Ensure joint sealing |

Packaging

1. Each roll of geomembrane is tightly sealed with moisture-proof packaging to prevent the geomembrane from being damaged by moisture during transportation.

2. Reinforced corner guards and buffer pads are used during transportation to prevent scratches, punctures and deformation.

3. For high-density polyethylene (HDPE)/linear low-density polyethylene (LLDPE) geomembranes, we use breathable packaging (for high temperatures) or thermal insulation liners (for cold climates) to avoid melting or embrittlement.

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()

About Us

Founded in 2008, Haoyang Environmental is an advanced geotechnical material manufacturer integrating R&D, manufacturing and construction. With many years of production and construction experience, it can produce products of different specifications according to customer project requirements. Our raw materials are all from China's top suppliers. With many domestically pioneered production lines and many invention patents, Haoyang Environmental has rich management experience in quality control and cost control, which makes our products have stable quality and reasonable prices. Under the concept of green development, Haoyang Environmental will continue to deepen innovation and lead the industry.

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()

![Nitrogen spray Double Rough HDPE Geomembrane Liner Nitrogen spray Double Rough HDPE Geomembrane Liner]()