Introduction

Geocomposite Drainage Layers (including Geocomposite Drainage Mats and Geocomposite Drainage Sheets) are revolutionizing landfill format with their most reliable hydraulic performance, value savings, and environmental benefits. By integrating 3D Drainage Networks for Landfills, Geocomposite Filters, and superior Drain Netting, these structures make sure environment friendly leachate and gasoline administration whilst assembly international regulatory standards. As technological know-how advances, Composite Drainage Nets will proceed to play a pivotal position in sustainable waste administration solutions.

Modern landfills require superior drainage options to control leachate and gases efficiently. Geocomposite Drainage Layers (also known as Geocomposite Drainage Mats or Geocomposite Drainage Sheets) have changed normal gravel layers due to their most beneficial performance, cost-effectiveness, and environmental benefits. This information explores six key factors of these systems, consisting of their structure, functions, and benefits over traditional methods.

Structure & Composition of Geocomposite Drainage Layers

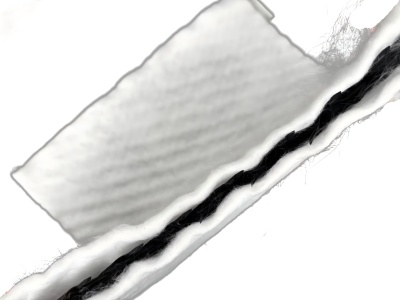

1. A Geocomposite Drainage Layer is a multi-layered device designed for most desirable fluid and gasoline transport. Its core factors include:

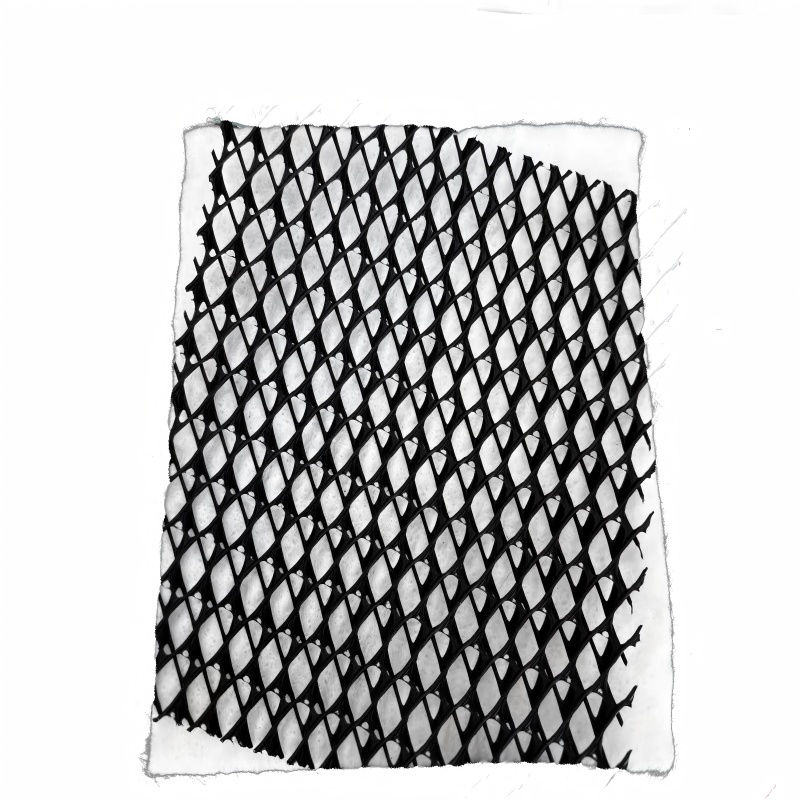

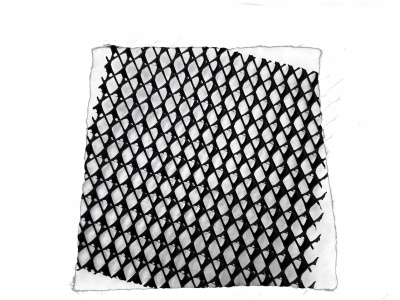

2. 3D Drainage Network for Landfills (Geonet Core): A high-strength polymer mesh (Drain Netting) that gives fast in-plane flow, making sure environment friendly leachate and gasoline removal.

3. Geocomposite Filter (Geotextile Layers): Nonwoven fabric stop soil intrusion whilst permitting liquid permeation, retaining long-term drainage efficiency.

4. Reinforcement Layers (Optional): Some Composite Drainage Nets consist of extra coatings or laminates for more suitable durability.

5. Compared to gravel, 3D Geocomposite Drainage structures are lighter, thinner, and provide greater drift rates, making them best for present day landfill engineering.

Key Functions in Landfill Systems

Geocomposite Drainage Sheets serve more than one imperative roles in landfill construction:

Leachate Management: The 3D Drainage Geocomposite swiftly collects and channels contaminated drinks to series systems, stopping liner damage.

Gas Ventilation: The open shape of the Drainage Net lets in landfill gases (methane, CO₂) to escape, decreasing strain buildup.

Filtration & Separation: The Geocomposite Filter blocks high-quality particles, stopping clogging of the Net for Drainage.

Protection Layer: Shields geomembranes from punctures triggered by using waste settlement.

These features make sure regulatory compliance whilst extending the landfill’s operational lifespan.

Advantages Over Traditional Drainage Methods

Compared to gravel-based systems, Geocomposite Drainage Mats provide full-size benefits:

Higher Hydraulic Capacity: The 3D Drainage Network for Landfills presents 10x larger float fees than gravel.

Space Efficiency: Thinner profiles (5-10mm vs. 300mm gravel) maximize landfill capacity.

Lower Installation Costs: Reduced cloth weight cuts transportation and labor expenses.

Long-Term Performance: Resists clogging higher than granular materials, making sure constant drainage.

Environmental Sustainability: Fewer uncooked substances are needed, reducing the carbon footprint.

These blessings make Geocomposite Drainage Sheets the desired desire for cutting-edge waste containment systems.

Applications in Landfill Design

Geocomposite Drainage Nets are used in a couple of landfill zones:

Base Liners: Installed above geomembranes to accumulate leachate earlier than it penetrates the barrier.

Side Slope Drainage: Prevents lateral liquid buildup alongside landfill walls.

Final Cover Systems: Facilitates fuel venting and rainwater drainage in closure caps.

Bioreactor Landfills: Enhances leachate recirculation in waste-to-energy systems.

The versatility of 3D Geocomposite Drainage makes it adaptable to a number of landfill configurations.

Performance Testing & Industry Standards

To make sure reliability, Geocomposite Drainage Layers should meet strict trying out protocols:

ASTM D4716: Measures transmissivity (flow capacity) underneath compressive loads.

GRI-GC8: Specifies cloth homes for Geocomposite Drainage Sheets.

EPA & EN Standards: Ensures environmental protection and long-term durability.

Manufacturers optimize Composite Drainage Nets for crush resistance, chemical stability, and UV protection, guaranteeing compliance with world landfill regulations.

Future Trends & Innovations

Emerging applied sciences are bettering Geocomposite Drainage Mats:

Smart Drainage Systems: Sensors embedded in 3D Drainage Geocomposites reveal go with the flow costs and clogging in actual time.

Biodegradable Geotextiles: Eco-friendly Geocomposite Filters limit environmental impact.

High-Strength Hybrids: Advanced polymers enhance the sturdiness of Drainage Nets beneath excessive loads.

These improvements will in addition optimize landfill drainage effectivity and sustainability.

About Us

As a pioneer in landfill drainage technology, Haoyang Environmental Technology ( Shandong ) Co., Ltd. manufactures high-performance geocomposite drainage layers designed to optimize leachate management and landfill stability. Our 3D drainage geocomposite systems combine robust drainage nets with filtration geotextiles, creating an integrated geocomposite drainage mat that replaces traditional gravel layers while enhancing flow efficiency (up to 5,000 m²/day in-plane capacity).

Engineered for durability and used in landfills worldwide, our geocomposite drainage net solutions reduce construction costs by 40% and extend system lifespan. Request specifications for net for drainage systems tailored to your project’s hydraulic demands.