Introduction

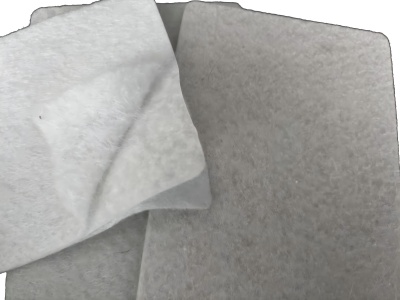

Composite Geomembrane for Mining is a high-strength geocomposite liner gadget particularly designed to meet the stressful anti-seepage challenges of the mining industry. Its core shape is a geotextile-bonded geomembrane, usually handy as a One Cloth One Membrane or, greater optimally, a Two Cloth One Membrane/Double Geotextile Geomembrane. It combines the top notch impermeability of HDPE composite geomembrane (or PP composite geomembrane) (a geocomposite water resistant membrane) with the protective, reinforcing, and drainage residences of geotextiles. It is broadly used in crucial services such as tailings pond composite geomembranes, heap leach sites, waste rock pile covers (which can serve as transient cowl composite liners), leachate ponds (wastewater lagoon composite liners), synthetic lake composite liners, and mine closure remediation (ecological restoration geocomposite). Its UV-resistant and chemical-resistant properties, as properly as its high-strength and strengthened format that meets ASTM Standards, make it a core engineering fabric for making sure mine environmental safety, stopping pollution, and making sure long-term stability.

Core Advantages and Key Considerations of Geocomposite Waterproof Membranes for Mining

1. Excellent Waterproofing: The core geomembrane layer offers an extraordinarily low permeability coefficient and is the coronary heart of the Geocomposite Waterproof Membrane.

2. Enhanced Mechanical Protection and Strength: The geotextile layer correctly protects the effortlessly punctured geomembrane layer from sharp rocks, building damage, and long-term masses frequent in mining environments, offering high-strength and bolstered properties. The geotextile-bonded geomembrane shape is key.

3. Interfacial Friction: The geotextile layer presents a true coefficient of friction with the cowl soil or waste material, enhancing slope balance (especially fundamental in tailings ponds). Textured composite liners can in addition decorate this performance.

4. Drainage/Venting Capabilities: The geotextile layer acts as a drainage layer for beverages or gases, stopping the buildup of head strain or air stress under the geomembrane, which should purpose the liner to flow or fail. Double-sided geocomposite (two fabric and one membrane) excels in this regard. Long-term durability: A geomembrane with the proper polymer (HDPE or PP) and system for mining environments (UV exposure, chemical exposure, temperature fluctuations, and microbial action) is mixed with a protecting layer (UV-resistant composite geomembrane, UV-stabilized composite liner, or chemical-resistant geocomposite) to make certain long-term performance. HDPE composite geomembrane is the favored preference for mining purposes due to its amazing chemical resistance, UV resistance, and durability.

5. Standardization and pleasant control: The geomembrane have to comply with stringent Composite Liner ASTM Standards and Geocomposite Seam Testing Methods and be manufactured via a dependable Composite Geomembrane Manufacturer/Best Composite Geomembrane Supplier in accordance with Composite Liner Manufacturing Standards.

6. Environmental compliance: It helps mines meet increasingly more stringent environmental regulations, forestall pollution, and defend water resources.

![Composite Geomembrane for Mining Composite Geomembrane for Mining]()

Why is a composite geomembrane necessary in mining? What problems does it solve?

Mining operations generate large amounts of fluid and solid waste that require safe containment and management, posing significant environmental risks (such as groundwater contamination, soil contamination, and dam instability). Composite geomembranes for mining play an indispensable role in the following key applications and are standard features in Tailings Pond Composite Geomembranes, Landfill Composite Liner Systems (referring to landfill-like facilities within mining areas, such as waste rock dump leachate collection areas), and Wastewater Lagoon Composite Liners:

1. Tailings Pond Liner Systems

Function: Serves as a primary or secondary liner to prevent tailings slurry containing heavy metals, chemicals (such as beneficiation agents), and fine particles from seeping into groundwater and surrounding soil. This is one of the most important applications of composite geomembranes in the mining industry.

Advantages of Composite: The geotextile layer protects the geomembrane from sharp tailings particles; provides a drainage layer, accelerating consolidation; and enhances overall structural stability, providing high-strength performance. UV-resistant composite geomembranes or UV-stabilized composite liners are often used for open-air environments.

2. Heap Leaching Liners

Function: Laid at the bottom of the heap leach site to prevent precious metal leachates containing cyanide, acid, or other leaching agents from seeping into the ground. The leachate is collected and transported to the treatment plant. Liners must possess excellent chemical-resistant geocomposite properties.

Composite Advantages: The geotextile layer protects the geomembrane from sharp rocks in the ore pile (increasing puncture resistance); provides a base layer, allowing for smoother liner installation; and helps distribute loads evenly.

3. Waste Rock/Low-Grade Ore Pile Cover Systems

Function: Applied to waste rock piles or temporarily untreated low-grade ore piles to prevent rainwater infiltration and acid mine drainage (AMD), or to control dust. Composite liners can also be used as temporary cover.

Composite Advantages: Provides a reliable anti-seepage barrier (geomembrane layer), while the geotextile layer protects the geomembrane, provides a growing medium for vegetation (if desired), or acts as a gas drainage layer. The textured composite liner surface increases friction with the cover soil.

4. Leachate Collection/Evaporation Pond Liner

Function: Prevents leakage of collected contaminated liquids (such as leachate from waste rock piles). This is a similar application to Reservoir Composite Waterproofing Membrane, Canal Lining Composite Geomembrane, and Artificial Lake Composite Liner.

Composite Advantages: Provides a reliable anti-seepage barrier and protection. Drainage Composite Geomembrane structures are particularly important in these applications, effectively draining liquids/gases beneath the membrane.

5. Closure/Remediation Projects

Function: In mine closure or environmental remediation projects, it is used to cover contaminated areas (such as old tailings ponds or contaminated soils), isolating rainwater and preventing further migration of pollutants. This falls under the category of Ecological Restoration Geocomposite.

Composite Advantages: Provides a long-term, stable cover system, with a geotextile layer supporting vegetation restoration (on top of the cover layer). Composite Geomembrane Lifespan is required to meet long-term isolation requirements.

![Composite Geomembrane for Mining Composite Geomembrane for Mining]()

Techinical Parameters

Parameter | Typical Value (HDPE as an example) | Test Standard | Application Significance |

Thickness | 1.0–3.0 mm (1.5–2.5 mm is common) | STM D5199 | Increased thickness for enhanced puncture resistance and durability |

Weight per Unit Area | 800–2500 g/m² | ASTM D5994 | Comprehensive strength index Tensile strength: ≥25 kN/m |

Tensile Strength | ≥25 kN/m (longitudinal/transverse) | STM D6693 | Resistance to construction tensile stress and foundation deformation |

Elongation at Break | ≥500% | ASTM D6693 | Material ductility and adaptability to settlement |

Right-angle Tear Strength | ≥100 N | ASTM D1004 | Resistance to localized tear propagation |

Compounded Break Resistance (CBR) | ≥3000 N | ASTM D6241 | Resistance to puncture by sharp tailings particles (key parameter) |

Interfacial Friction Angle | 25°–35° (with soil/waste rock) | ASTM D5321 | Slope stability design basis |

Company’s Strength

As specialized composite geomembrane manufacturers, we engineer high-strength geocomposite liners with patented "One Cloth One Membrane" construction, combining needle-punched nonwoven geotextiles and 2mm HDPE composite geomembranes for extreme mining environments. Our UV-resistant composite geomembranes deliver 35 kN/m geocomposite tensile strength and chemical resistance to pH 1.5 acidic leachate, certified to composite liner ASTM standards (D7885/D7238). Proven in global tailings pond composite geomembrane installations across Chilean copper mines and Canadian oil sands, these textured composite liners enhance slope stability with 35° friction angles. Offering factory direct pricing on custom-sized rolls with documented composite geomembrane lifespan exceeding 50 years—request your tunnel waterproofing geocomposite technical dossier or tailings pond case studies.