What’s the Difference Between Smooth and Textured Geomembranes?

If you’ve ever been involved in selecting liners for containment projects, you’ve likely faced the classic choice: smooth or textured geomembrane? It’s not just an aesthetic preference—it’s a decision that influences everything from installation speed to long-term stability. Both are typically made from high-density polyethylene (HDPE), but that’s about where the similarities end. So, what actually sets them apart in practice?

It All Starts with the Surface

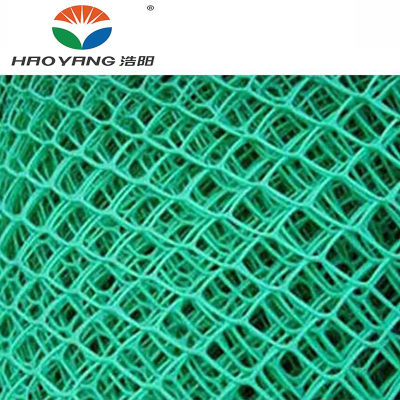

The most obvious difference is tactile. Run your hand over a smooth geomembrane, and it feels… well, smooth. Slippery, even. That’s because HDPE smooth geomembrane is manufactured using a flat-die extrusion process that produces a consistent, low-friction surface. This isn’t just for show—that uniformity translates into high tensile strength and solid chemical resistance. It’s the workhorse liner for base applications where things stay relatively flat.

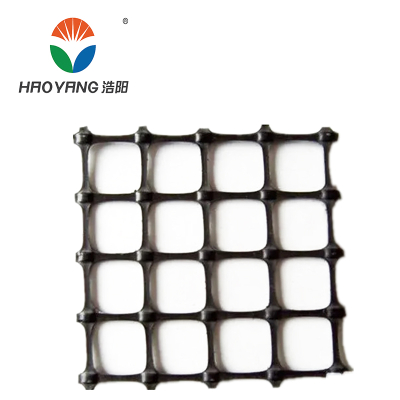

Then there’s its rougher cousin. Textured geomembrane gets its bumpy profile from production techniques like co-extrusion or impingement. One common method involves blowing a texturing agent onto one or both sides of the sheet while it’s still semi-molten. This creates a surface that’s inherently grippy. While you might trade off a tiny bit of puncture resistance compared to smooth membrane HDPE, you gain something arguably more valuable in the right context: friction. When evaluating a standard HDPE smooth geomembrane versus a textured one, it's clear that texture fundamentally alters performance parameters.

When Friction is Your Friend (or Enemy)

Here’s where theory meets the dirt. On a flat base liner, HDPE smooth geomembrane performs beautifully. It’s easy to install, and its low surface friction isn’t a problem. But put that same material on a slope, and you might be courting trouble. Its low interface shear strength means it can slide against soils or geotextiles, especially when wet. We’ve all seen photos of liner wrinkles—sometimes that’s more than just a cosmetic issue.

Textured geomembrane exists almost exclusively to solve this problem. That roughened surface dramatically increases the interface friction angle. In practical terms, it “bites” into adjacent materials, providing resistance against down-slope creep. This makes textured geomembrane the material of choice for landfill side slopes, caps, and reservoir embankments. It’s the difference between hoping your liner stays put and knowing it will. The enhanced performance of this type of membrane HDPE on inclines is why engineers frequently specify it over smooth alternatives in their designs.

How They Play with Other Materials

Geomembranes rarely work alone. They’re part of a layered system involving geotextiles, drainage composites, and soils. This is where interaction behavior gets interesting.

Smooth geomembrane has minimal resistance against other layers. While this can simplify installation (sheets slide easily into position), it can become a liability under differential settling or seismic loading. Layers can shift independently. A typical HDPE smooth geomembrane works well in simple, stable composite liners where little shear stress is anticipated.

Textured geomembrane, by contrast, interlocks with neighboring materials. This composite action enhances overall system stability, particularly in challenging subgrade conditions. It’s why you’ll often find textured geomembrane specified in mining applications or heap leach pads where stability is non-negotiable. The mechanical bonding provided by this type of membrane HDPE can significantly improve the safety factor of containment systems on marginal sites.

The Installation Grind

There’s a misconception that textured geomembrane is just a “drop-in” replacement for smooth. Not quite. Ask any crew that’s seamed both: installation isn’t the same.

Smooth HDPE smooth geomembrane is straightforward to weld. The consistent surface allows wedge welders or extrusion welders to produce clean, continuous seams with minimal fuss. Deployment is fast, making this membrane HDPE ideal for projects with tight deadlines or large, accessible areas.

Textured material requires more patience. The textured surface can trap microscopic moisture or air during seaming, potentially creating weak points. Experienced installers often lightly grind the seam area to create a smooth welding path when working with textured geomembrane. It’s an extra step, but one that pays off in weld integrity—especially on critical slopes where seam failure is not an option. Properly installing this type of membrane HDPE demands skilled labor and careful quality control.

Choosing Based on Reality, Not Just Specs

So, which one should you use? It boils down to function and geometry.

HDPE smooth geomembrane remains the cost-effective champion for ponds, tank farms, and flat containment areas. It’s durable, predictable, and installs quickly. For many applications, this type of membrane HDPE provides perfectly adequate performance without unnecessary expense.

But when the site plan shows slopes steeper than 3:1, or when the underlying soil has questionable shear strength, that’s where textured geomembrane earns its keep. Yes, it costs more per square meter. But that premium buys insurance against slope failure—a risk that’s far more expensive to fix down the line. In such scenarios, opting for a textured geomembrane rather than a standard HDPE smooth geomembrane becomes an exercise in risk management rather than simple material selection.

Conclusion

There’s no universal “best” geomembrane. There’s only the best one for your specific site conditions, slope angles, and risk tolerance. HDPE smooth geomembrane offers efficiency and proven performance in flat applications. Textured geomembrane provides essential grip and peace of mind on slopes. Understanding how each type of membrane HDPE behaves in different environments is key to making the right choice.

Before you decide, walk the site. Look at the cross-sections. And remember: the cheapest liner per square meter isn’t always the cheapest solution when you consider long-term performance.