How to Choose Geomembrane for Pond: A Comprehensive Guide

Remember when building a pond meant wrestling with clay, pouring concrete, or laying down flimsy plastic sheeting? Those methods often led to leaks, constant patching, and plenty of headaches. Things have changed. These days, more engineers and site managers are turning to HDPE Lining for Ponds—a material that doesn't just hold water but actually improves over time. We're going beyond the sales brochures to look at what really makes these High Density Polyethylene HDPE Liners stand out. From the science behind the plastic to why HDPE Liner Welding matters more than you think, let's break down why HDPE is turning water containment on its head.

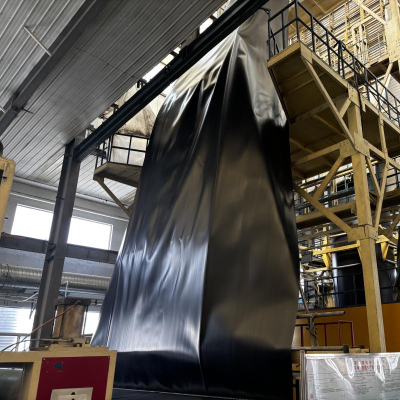

It's All in the Molecules: Why HDPE Doesn't Quit

So what's the big deal with HDPE Lining for Ponds? It starts with its structure. Think long, tough polymer chains packed tightly together—that's what gives it serious tear resistance and makes it hard to puncture. And unlike some liners that get brittle in the sun, High Density Polyethylene HDPE Liners are typically formulated with carbon black for UV protection. It's not just sitting there blocking water; it's actively holding up under pressure, season after season. You're not getting that with PVC or EPDM. When properly installed with quality HDPE Liner Welding, you’ve got a system that’s built to last.

Safe for Fish, Water, and Pretty Much Everything Else

Here's something that doesn't always make the spec sheets: HDPE Lining for Ponds is chemically inert. It won't react, break down, or leach anything into your water—which is kind of a big deal if you're growing fish, storing drinking water, or working in a sensitive environment. While other materials can introduce plastics or chemicals into your system, High Density Polyethylene HDPE Liners just… sit there. Doing their job. No surprises. And when the seams are done right with expert HDPE Liner Welding, you get a complete barrier that won't compromise water quality.

Why Welding Can Make or Break Your Liner

Let's be real: the best HDPE Lining for Ponds is useless if the seams fail. That's where fusion welding comes in. It's not like taping something together; it's literally melting the panels into one continuous piece. Good crews use automated wedges or extruders and test every seam. Skip professional HDPE Liner Welding, and you're rolling the dice. It's why serious projects don't cut corners on installation. The integrity of any High Density Polyethylene HDPE Liners system depends completely on the quality of its welded seams.

From Frozen Solid to Desert Sun: HDPE Handles It All

One of the less obvious perks of HDPE Lining for Ponds? This stuff works everywhere. I've seen it in freezing Canadian retention ponds and desert mining sites where surface temps hit 70°C. It doesn't crack like concrete or get soft and gummy like some polymers. Thermal expansion? Minimal. High Density Polyethylene HDPE Liners just adapt. That kind of reliability makes HDPE Lining for Ponds a safe bet for jobs where failure isn't an option. And with proper HDPE Liner Welding, those thermal cycles won't stress the seams either.

Pay Now, Save for Decades

Look, HDPE Lining for Ponds isn't the cheapest upfront. But if you've ever had to re-line a pond or fix a leaky basin, you know the real costs add up later. With High Density Polyethylene HDPE Liners, you're looking at 30, 40, sometimes 50 years of service. No coatings, no annual treatments—just set it and (basically) forget it. It's a classic case of spending smart now to save big later. Just make sure your investment is protected with quality HDPE Liner Welding from the start.

The Green Side of a Plastic Liner

I know—it feels weird to call plastic "green." But HDPE Lining for Ponds is often made with recycled content, and at end-of-life, it can be recycled again. More importantly, High Density Polyethylene HDPE Liners prevent contamination and save water by eliminating seepage. In many cases, using HDPE Lining for Ponds is the most environmentally responsible choice for a project, precisely because it protects soil and groundwater long-term. Even the HDPE Liner Welding process produces minimal waste when done correctly.

Way More Than Decorative Ponds

Sure, HDPE Lining for Ponds handles garden water features. But its real value shows up in tougher gigs:

Containing mining tailings and chemical leachates

Lining aquaculture tanks for shrimp and fish production

Capping landfills to keep methane and leachate in check

Floating covers that reduce evaporation in dry regions

In every case, High Density Polyethylene HDPE Liners provide the durability needed, while professional HDPE Liner Welding is what keeps everything securely contained.

Wrap-Up: The Takeaway Isn't Just "It Works"

Choosing HDPE Lining for Ponds isn't about finding the cheapest roll of plastic. It's about reducing risk, avoiding callbacks, and building something that lasts. High Density Polyethylene HDPE Liners do that—with a track record to back it up. When you pair the right material with proper HDPE Liner Welding and solid installation, you're not just building a pond. You're building peace of mind that'll hold up for decades.