Comparison of Three Common Geotextiles: Which One Is More Suitable for Your Project?

In modern civil engineering, environmental protection engineering and water conservancy projects, Geotextile has become an indispensable functional material. According to its manufacturing process and structure, Geotextile is mainly divided into three categories: Woven Geotextile Fabric, Non Woven Geotextile and Knitted Geotextile Fabric.

Different types of Geotex Fabric have their own mechanical properties and applicable scenarios. This article will systematically sort out the characteristics, uses and technical parameters of the three geotextiles for you to help you accurately select materials.

Woven Geotextile Fabric

This Geotextile is woven by polyester or polypropylene yarn in a warp and weft interlacing manner, and is often used in structures with high bearing capacity requirements.

- Features

• High tensile strength and low elongation: suitable for structural reinforcement and suppression of soft soil settlement.

• Tight structure and stable size: not easy to deform after laying.

• Average water permeability, usually used with drainage layer

- Application Areas & Cases

1. Soft foundation reinforcement (such as roads and docks)

Case: High-strength woven geotextile fabric (tensile strength ≥ 100 kN/m) is used for roadbed reinforcement in the Indonesian highway project.

Recommended parameters: PET material, gram weight ≥ 300 g/m².

2. Retaining wall and landfill structure stabilization layer

Case: PP Woven Geotextile with a tensile strength of 120kN/m is used in the Malaysian landfill project,

Recommended parameters: unit mass ≥ 400 g/m², elongation ≤ 15%.

3. Embankment and slope support

Case: High-strength PET woven fabric is used in the slope reinforcement project of a hydropower station in South America.

Parameter recommendations: UV-resistant treatment, bidirectional tensile strength ≥ 80 kN/m.

|  |

| Woven Geotextile Fabric | |

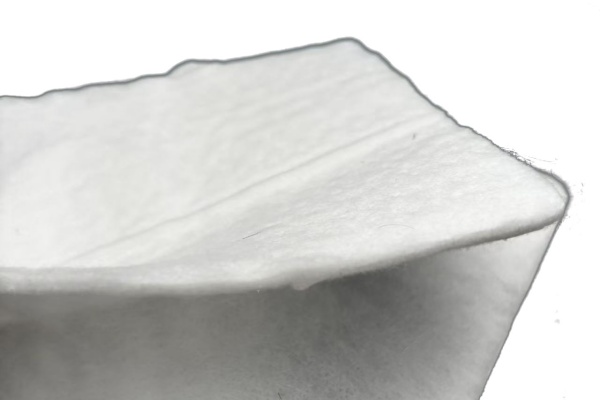

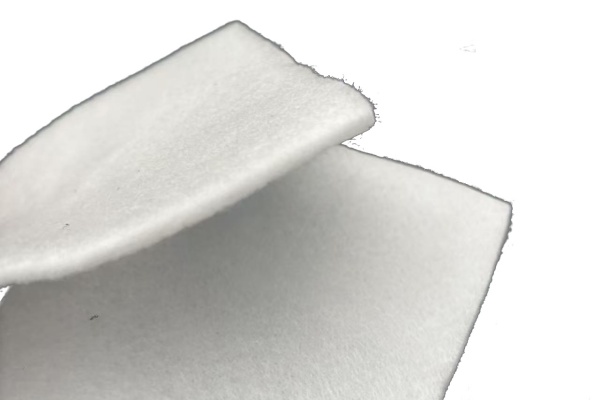

Non Woven Geotextile

Non Woven Geotextile is usually made of polyester filament or polypropylene staple fiber through needle punching or hot pressing, and has good water permeability and filtration ability.

- Features

• Excellent drainage and filtration: mostly used for infiltration layer and drainage layer.

• Soft and easy to construct: strong ability to adapt to terrain.

• Strong puncture resistance: can be used as a protective layer for HDPE geomembrane.

- Application Areas & Cases

1. Filtration and drainage layer of infiltration system

Case: 400 g/m² Geotextile Polyester filament cloth is used in the bottom structure of the Vietnamese urban landfill.

Recommended parameters: water permeability coefficient ≥ 1×10⁻² cm/s, tensile strength ≥ 15 kN/m.

2. Geomembrane protective layer (used with Geotextile Cloth)

Case: A chemical pool project in Africa uses 500 g/m² staple cloth to prevent the membrane from being punctured by gravel.

Recommended parameters: puncture resistance ≥ 1.5 kN, thickness ≥ 4 mm.

3. Road base isolation layer

Case: A highway in the desert area of the Middle East uses 300 g/m² Nonwoven Geotextile as an isolation + drainage composite layer.

Parameter recommendation: tensile strength ≥ 10 kN/m, elongation ≥ 50%.

|  |

| Non Woven Geotextile | |

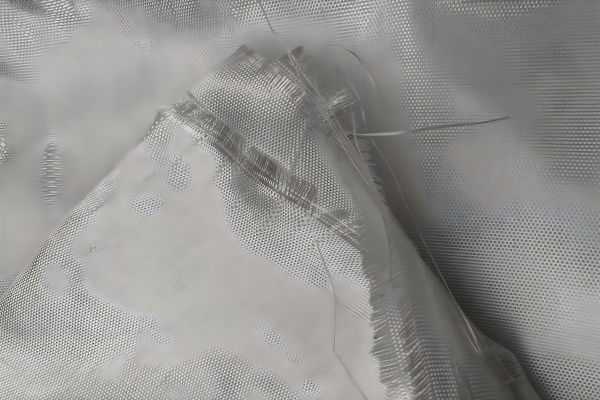

Knitted Geotextile adopts a yarn loop winding structure with excellent flexibility, which is suitable for applications with drastic terrain changes or special structures.

- Features

• High flexibility and ductility: suitable for areas with large deformations.

• Can be compounded into multifunctional geotechnical materials (such as water guide + reinforcement).

• Highly customizable, but complex production and high cost.

- Application Areas & Cases

1. Reinforcement in irregular terrain or settlement areas

Case: In the slope greening project in the Indian mountain area, Knitted Geotextile is used to prevent surface slippage.

Recommended parameters: elongation ≥ 80%, gram weight ≥ 400 g/m².

2. Eco-bag, slope protection cloth structure

Case: In a river ecological restoration project, Geofabric knitted fabric is used as the surface material of the eco-bag, taking into account both water permeability and structural strength.

Parameter recommendations: gram weight 300–600 g/m², tear resistance ≥ 0.8 kN.

3. Underground structure drainage composite system base fabric

Case: The Singapore subway drainage composite layer uses Knitted base fabric and three-dimensional mesh layer composite.

Parameters: Post-compounding tensile strength ≥ 25 kN/m, thickness 5–10 mm.

|  |

| Knitted Geotextile Fabric | |

Woven vs Nonwoven vs Knitted Geotextile Comparison Table:

Parameters | Woven Geotextile Fabric | Non Woven Geotextile | Knitted Geotextile Fabric |

Material Type | PET/PP filament | Polyester filament or Staple fiber | PET/PP yarn |

Tensile Strength (kN/m) | 20–200 | 8–60 | 10–100 (customized) |

Elongation (%) | ≤25% | 40–80% | 50–150% |

Weight ((g/m²) | 100–600 | 100–1200 | 300–800 |

Water Permeability (cm/s) | 10⁻⁵ ~ 10⁻³ | 10⁻³ ~ 10⁻¹ | 10⁻⁴ ~ 10⁻² |

Applicable Scenarios | Reinforcement, isolation, structural support | Drainage, protection, filtration | Eco bags, complex terrain, composite materials |

Whether it is Woven And Non Woven Geotextile or dedicated Knitted Geotextile Fabric, the selection should be weighed according to the actual needs of the project (such as load-bearing capacity, permeability, flexibility, cost).

If you have any questions about specific models, construction matching solutions, or Geofabric purchases, please leave a message or contact us for professional advice and sample support.

Haoyang’s Geotextiles Products

Haoyang Environmental Technology (Shandong) Co., Ltd. was established in 2008 and located in Shandong Province, China. We are an international environmental technology integrated service provider integrating environmental protection material research and development and manufacturing, environmental protection engineering consulting and design, construction, ecological governance and hazardous waste treatment. We have more than 20 modern environmental protection engineering material production lines with strong annual production capacity, stable quality and leading technology.

|  |

In the field of geotextiles, Haoyang provides a full range of solutions:

• High-strength woven geotextiles (Woven Geotextile Fabric), with excellent tensile properties and structural reinforcement capabilities, are widely used in highways, railways, ports and soft foundation reinforcement projects;

• High-permeability non-woven geotextiles (Non Woven Geotextile), formed by filament or staple needle punching, suitable for drainage, filtration, isolation, protection and other functional projects;

• Flexible knitted geotextiles (Knitted Geotextile Fabric), with flexible structure and strong fit, are suitable for special reinforcement applications in complex terrain or composite material systems.

Our products cover a variety of materials and structures such as Geotextile Polyester, Geotex Fabric, Geofabric, Woven and Non Woven Geotextile, etc., supporting customized production and sample processing to meet the differentiated needs of global customers for different engineering environments.

|  |

At the same time, Haoyang can also provide more than 100 kinds of geosynthetics, including HDPE geomembrane, composite geomembrane, sodium-based bentonite waterproof blanket(GCL), geocomposite drainage net, etc., which are widely used in water conservancy projects, transportation infrastructure, solid waste and hazardous waste landfill, tailings pond management and environmental protection restoration projects.

|  |

Our products have been exported to many countries and regions such as Southeast Asia, South America, Africa, and the Middle East, which have gained a great reputation in these markets. In the future, We will continue to be driven by technological innovation and guaranteed by stable product quality, and is committed to providing reliable engineering material solutions to global customers.

|  |

Whether you need to purchase high-strength woven geotextile in large quantities, or look for nonwoven geotextile for filtration and drainage systems or knitted geotextile fabric that can flexibly adapt to terrain, Haoyang can provide you with professional and efficient service support.