"Hao" Product – Geomembrane for Oxidation Ponds

Common Challenges of Conventional Geomembranes

1. Environmental Stress Cracking (ESC)

HDPE geomembranes: Resin density range 0.935–0.940 g/cm³, high crystallinity.

LLDPE geomembranes: Resin density 0.919–0.925 g/cm³, low crystallinity.

For landfill capping, ESC resistance is a critical performance requirement.

2. Differential Settlement

Post-closure, uneven waste settlement creates localized depressions.

Capping materials undergo large deformations as terrain shifts.

Low deformability leads to stress buildup, causing cracks.

3. Membrane Bulging & Stress Concentration

Gas accumulation beneath the membrane forms localized bulges, leading to tensile deformation or rupture.

4. Biogas Pressure Fluctuations & Fatigue Failure

Biogas pressure variations (typically 5–10 kPa) cause repeated expansion/contraction.

Welded seams are prone to fatigue cracking.

Features of Oxidation Pond-Specific Geomembrane

1. Superior Performance

In landfill capping, LLDPE geomembranes match HDPE in:

High tensile strength

Excellent water vapor barrier

Superior methane gas resistance

Fully complies with landfill capping technical standards.

2. High Multiaxial Elongation

LLDPE outperforms HDPE in landfill applications due to:

Differential settlement

Methane gas generation during waste decomposition.

Key elongation comparison:

HDPE: ~15%

LLDPE: ≥30%

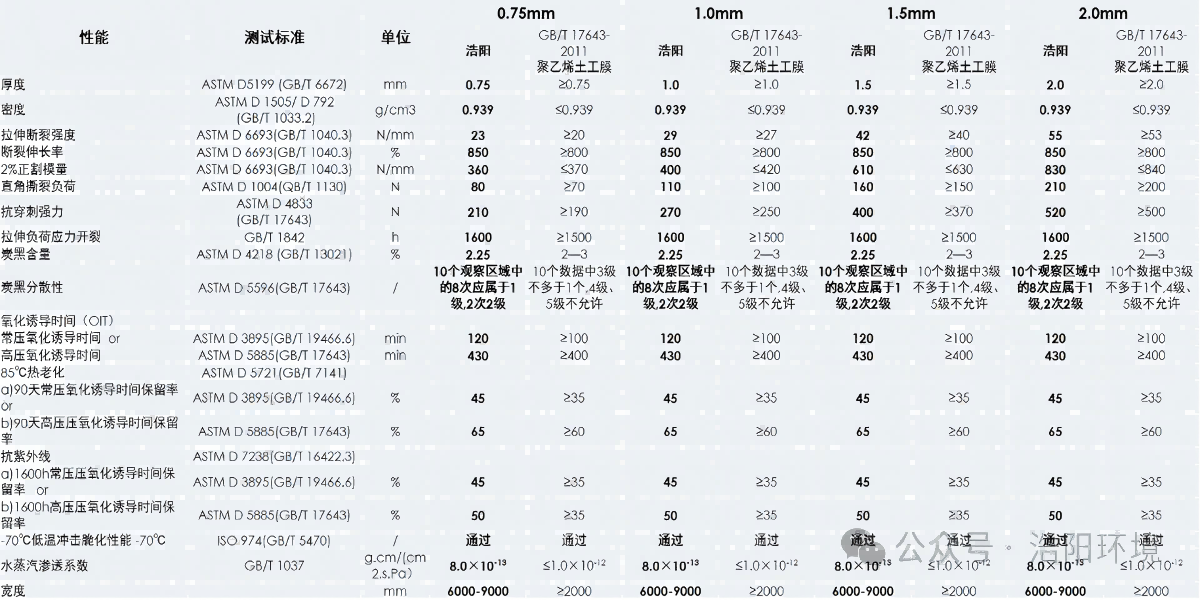

Technical Specifications