Geosynthetic Materials Revolution: HDPE Geomembranes and Acid - Alkali Resistant Solutions Lead the Way

In the dynamic landscape of the geosynthetic materials industry, recent developments in HDPE geomembranes and specialized solutions like acid - alkali resistant geosynthetics and anti - silt three - dimensional composite drainage nets are transforming infrastructure projects and environmental protection efforts globally. These advancements not only address long - standing engineering challenges but also signify a shift towards more sustainable and high - performance solutions.

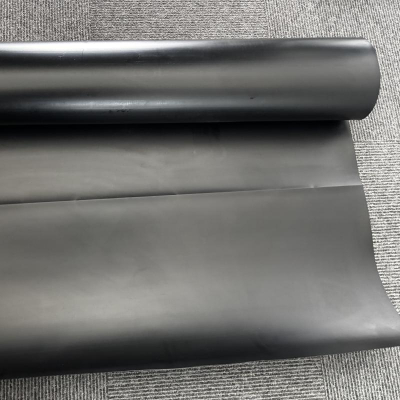

HDPE geomembranes, a staple product in the geosynthetics sector, have undergone significant technological upgrades. Newly developed HDPE geomembranes feature enhanced resistance to environmental stress cracking and UV degradation. Boasting an extremely low permeability coefficient (1×10⁻¹⁷ cm/s) and remarkable chemical stability, these geomembranes are becoming the go - to choice for major projects such as landfill liners, reservoir seepage control systems, and wastewater treatment facilities. At the Geosynthetics International Conference, a leading manufacturer revealed, "Our latest HDPE geomembranes cut installation time by 25% and extend the service life to over 50 years, optimizing both efficiency and durability."

Acid - alkali resistant geosynthetics are making waves, especially in the chemical and metallurgical industries. Engineered to endure extreme pH environments, these specialized geomembranes act as a reliable safeguard against hazardous material leakage, ensuring strict regulatory compliance. In hydrometallurgy, where operations involve potent acids and alkalis, acid - alkali resistant geomembranes provide a robust barrier, protecting soil and water resources from contamination and supporting the industry's sustainable development.

Another area of rapid growth is anti - silt three - dimensional composite drainage nets. Designed for complex drainage scenarios, such as tailings ponds and red mud storage areas in hydrometallurgy, these nets prevent clogging while maintaining high - efficiency water flow. Their ability to ensure long - term stable operation of drainage systems has led to increased adoption across various large - scale industrial projects.

"Sustainability and innovation are at the forefront of our product development," states a senior industry executive. Many companies are now investing in research to create recyclable geosynthetic products, in line with global green initiatives. Bentonite waterproof blankets (GCLs), renowned for their eco - friendliness and excellent waterproofing performance, are seeing a surge in demand for green building and underground seepage control projects.

With the continuous acceleration of urbanization and infrastructure construction worldwide, the geosynthetic materials market is projected to experience substantial growth in the coming years. Driven by ongoing innovation in product performance and sustainability, HDPE geomembranes, acid - alkali resistant geosynthetics, anti - silt drainage nets, and other advanced geosynthetic solutions are poised to play an even more pivotal role in building a resilient and environmentally friendly future for global infrastructure.