Product Introduction:

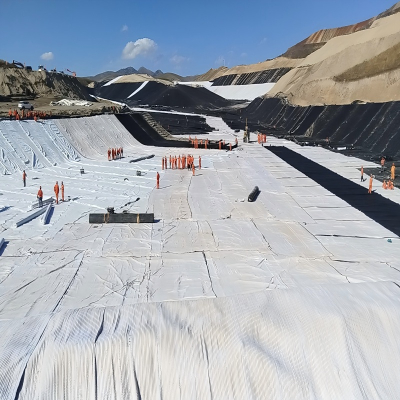

Haoyang Environmental's engineered geosynthetic clay liner combines high-purity sodium bentonite (≥24mL/2g swell index) with precisely balanced woven/nonwoven geotextiles (300/400g/m²) through optimized needle-punching technology (220±10 punches/cm²). The composite delivers exceptional hydraulic performance (≤1×10⁻⁹ cm/s per ASTM D5887) while maintaining 18kN/m tensile strength (ASTM D4595) in both machine and cross-machine directions. Prefabricated in 5-6mm thick rolls (4.8m×60m standard size), our GCL enables installation rates exceeding 500m²/day with proper equipment, supported by pre-marked overlap indicators that reduce seam errors by 90%.

![Needle-Punched Bentonite Geotextile Composite Needle-Punched Bentonite Geotextile Composite]()

Product Features:

High Swell Capacity - Expands up to 15 times its dry volume when hydrated.

Chemical Compatibility - Resistant to most contaminants in soil and groundwater.

Long-Term Performance - Maintains waterproofing properties indefinitely when properly confined.

Engineered Performance Characteristics

1. Volumetric Expansion:

15× dry volume swell capacity (ASTM D5890).

95% swell potential retained after 50 wet-dry cycles.

Uniform hydration guaranteed by needle-punch fiber network.

2. Chemical Resilience:

pH stability range: 3–11 (12-month immersion testing).

≤5% swell reduction in 10,000mg/L Ca²⁺ solutions.

Hydrocarbon-resistant formulations available.

3. Durability Assurance:

50-year service life projection (ISO TR 20432).

UV resistance: ≤10% tensile reduction after 3,000hr exposure.

Bentonite retention: >99% under 50kPa hydraulic pressure.

![Needle-Punched Bentonite Geotextile Composite Needle-Punched Bentonite Geotextile Composite]()

Technical Validation

All production batches undergo:

Full-width permeability testing (ASTM D6766).

Peel strength verification (≥65N/100mm).

Third-party certified swell index analysis.

Large-format shear testing (1m×1m samples).

Project-Specific Solutions:

Custom roll widths up to 6m.

Pre-hydrated edge seals for rapid activation.

Conductive versions for leak detection.

RFID-enabled quality tracking.

Business Strength:

With cutting-edge production technology, we manufacture premium quality geocomposites and drainage systems that meet the most demanding project specifications and international standards.

Haoyang operates the industry's most advanced GCL production facility featuring:

Automated needle-punching systems with real-time density monitoring.

Robotic quality control (laser thickness measurement ±0.1mm).

In-house ISO 17025 accredited testing laboratory.

Blockchain-based material traceability.

![Needle-Punched Bentonite Geotextile Composite Needle-Punched Bentonite Geotextile Composite]()