Product Introduction:

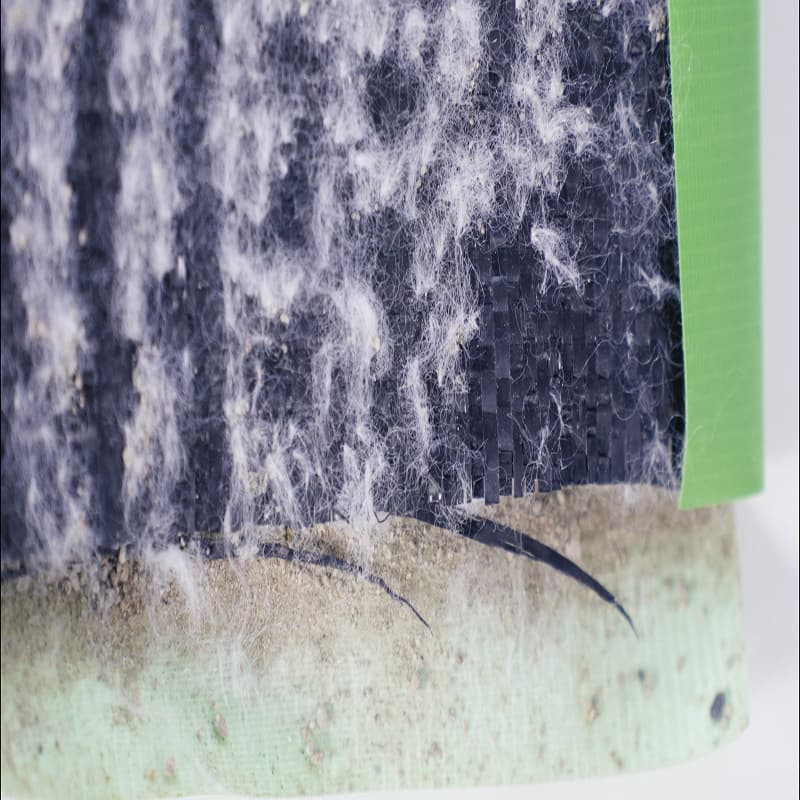

Our Landfill Cap Bentonite Liner with Geotextile is a highly specialized geosynthetic solution engineered to meet the demanding requirements of landfill capping and various infrastructure projects. The liner features a textured surface that offers exceptional bonding capabilities with shotcrete, making it an ideal choice for subway and road tunnel applications. This unique texture ensures a secure and seamless connection, enhancing the overall structural integrity and waterproofing performance of the tunnel lining system.

When exposed to water pressure, the bentonite within the liner swells effectively to seal cracks up to 10mm in width. This self-sealing property provides a reliable and long-lasting barrier against water infiltration, preventing potential environmental contamination and structural damage. Additionally, the liner is integrated with fire-retardant additives that meet the stringent standards of ASTM E84 Class A. This fire-resistant feature significantly enhances safety in projects where fire protection is a critical concern, such as in urban infrastructure construction.

![Landfill Cap Bentonite Liner with Geotextile Landfill Cap Bentonite Liner with Geotextile]()

Product Applications:

1. Oil & Gas Pipeline Encapsulation:

In the oil and gas industry, protecting buried pipelines from corrosion is of utmost importance. Our Landfill Cap Bentonite Liner leverages the cathodic protection properties of bentonite to safeguard pipelines. When the liner is applied around the pipeline, the bentonite creates a protective electrochemical environment that inhibits the corrosion process. This not only extends the lifespan of the pipelines but also reduces the risk of leaks and potential environmental disasters. For example, in major oil pipeline projects across [region], our liners have been successfully installed, providing long-term corrosion protection and ensuring the safe and efficient transportation of oil and gas resources.

2. Artificial Lake Construction:

For the construction of recreational lakes and decorative water features, our self-sealing bentonite liners offer an excellent solution. The liner's ability to swell and seal under water pressure ensures that the lake retains its water volume, minimizing seepage and water loss. The natural and non-toxic properties of bentonite also make it environmentally friendly, creating a safe habitat for aquatic plants and wildlife. In numerous artificial lake projects in urban parks and residential developments, our liners have been used to create beautiful and sustainable water landscapes, enhancing the aesthetic appeal and ecological value of the areas.

3. Highway Subgrade Stabilization:

In highway construction, maintaining the stability of the subgrade is crucial for the durability and safety of the road. Our bentonite-soil mixes, incorporated into the roadbeds, effectively reduce permeability. By preventing water from infiltrating the subgrade, these mixes help to avoid frost heave, a common problem in cold climates where the freezing and thawing of water in the soil can cause the road surface to crack and deform.

![Landfill Cap Bentonite Liner with Geotextile Landfill Cap Bentonite Liner with Geotextile]()

Product Features

1. Superior Bonding: The textured surface of the liner enables strong adhesion to shotcrete, ensuring a reliable connection in tunnel construction. This feature eliminates the risk of delamination and enhances the overall performance of the tunnel lining system.

2. Efficient Self-Sealing: With the ability to seal cracks up to 10mm under water pressure, the liner provides an effective waterproofing solution. Its self-sealing property reduces the need for frequent repairs and maintenance, saving time and costs in long-term project operation.

3. Enhanced Fire Safety: The inclusion of ASTM E84 Class A fire-retardant additives makes the liner highly resistant to fire. This feature complies with strict fire safety regulations, providing an added layer of protection in infrastructure projects.

Quality Assurance:

At Haoyang Environmental, we uphold the highest standards of quality in the production of our Landfill Cap Bentonite Liner with Geotextile. We source premium-grade raw materials, including high-quality bentonite and durable geotextile, from trusted suppliers. Each batch of raw materials undergoes rigorous inspection to ensure their purity, physical properties, and chemical stability.

Our manufacturing processes are carefully monitored and controlled, adhering to international quality management systems such as ISO 9001. The liners are subjected to a series of comprehensive tests, including bonding strength tests with shotcrete, swelling capacity tests under water pressure, and fire resistance tests in accordance with ASTM E84 standards. These stringent quality control measures guarantee that our products consistently meet or exceed industry requirements and deliver reliable performance in every project.

Technical Services:

Our technical team offers comprehensive support throughout the project lifecycle. During the project planning phase, we work closely with clients to understand their specific needs, site conditions, and project requirements. Based on this information, we provide detailed product selection advice, customized design solutions, and technical specifications to ensure the most suitable application of our Landfill Cap Bentonite Liner.

For on-site installation, our experienced technicians are available to provide guidance and training. They assist the installation team in proper handling, cutting, and seaming of the liner, as well as in ensuring correct application techniques for bonding with shotcrete or other construction materials. Post-installation, we offer long-term technical support, promptly responding to any inquiries, providing maintenance recommendations, and conducting regular performance evaluations to ensure the continued effectiveness of our products.

Business Strength:

Haoyang Environmental stands out in the geosynthetics industry by seamlessly combining innovative material science with advanced manufacturing techniques. Our R&D team continuously explores new materials and formulations, leveraging the latest scientific discoveries to develop geosynthetic products with enhanced performance and durability. By integrating these innovations into our state-of-the-art manufacturing facilities, we are able to produce high-quality geosynthetics that meet the diverse needs of containment, reinforcement, and filtration applications.

Whether it's protecting the environment in landfill projects, ensuring the stability of infrastructure in transportation construction, or supporting sustainable development in various industries, our products are designed to provide reliable and long-lasting solutions. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a trusted partner in the geosynthetics market, and we remain dedicated to driving the industry forward with our cutting-edge products and services.

![Landfill Cap Bentonite Liner with Geotextile Landfill Cap Bentonite Liner with Geotextile]()