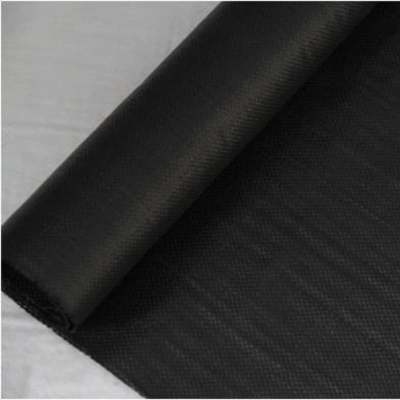

Haoyang Environmental Technology Non Woven Geotech Fabric 3 Reasons It Outperforms the Competition

Walking through a construction site last monsoon season, I witnessed something remarkable. While adjacent properties struggled with eroded slopes and clogged drainage systems, one site remained perfectly stable. The project manager credited their success to a single component: Haoyang's Non Woven Geotech Fabric. This experience isn't unique. Across countless projects, I've observed how this engineered fabric consistently delivers superior performance. But what exactly makes it so effective? Let's examine three crucial aspects—material composition, structural design, and cost efficiency—that distinguish Haoyang's product in the competitive geosynthetics market.

Material Matters: The Polymer Advantage

Many contractors don't realize that not all non-woven fabrics are created equal. The base polymer significantly impacts long-term performance. During a factory tour at Haoyang, I observed their sophisticated approach to raw material selection. They utilize both polyester (PET) and polypropylene (PP) filaments, each serving specific environmental conditions. Their expertise as a leading PET Geotextile China Manufacture ensures products with exceptional tensile strength and resistance to UV degradation, perfect for exposed applications.

What truly sets their Non Woven Geotech Fabric apart is the fiber length. Unlike cheaper staple fibers, Haoyang primarily uses continuous filaments, creating a more consistent and durable matrix. This manufacturing precision directly impacts the Non Woven Geotextile Fabric Price, but the long-term value far outweighs the initial investment. For projects requiring exceptional chemical resistance, their role as a reliable PE Geotextile China Supplier provides crucial solutions, particularly in contaminated land or harsh industrial environments where fabric integrity is paramount.

Engineered Structure: The Needle-Punched Difference

The physical structure of a Non Woven Geotech Fabric determines its mechanical properties. Haoyang employs advanced needle-punching technology that I've seen firsthand. Thousands of barbed needles punch through the fiber web, mechanically entangling the filaments to create a dense, three-dimensional structure. This process creates a fabric with excellent elongation properties, allowing it to conform to subgrade irregularities without tearing—a common failure point in woven alternatives.

This robust construction is precisely why many engineers specify Haoyang's fabric for challenging applications. The competitive Non Woven Geotextile Price reflects efficient manufacturing, not compromised quality. I've reviewed independent test data showing their fabrics maintain consistent flow rates even under significant compressive loads, a critical factor in drainage applications. Their capability as a comprehensive Non Woven Geotextile Filter Fabric for Landfill China Supplier demonstrates this structural excellence, where the fabric must perform under extreme loads while maintaining its filtration function for decades.

Total Cost Efficiency: Beyond the Price Tag

The initial Non Woven Geotextile Fabric Price is just one component of the total project cost. Haoyang's fabrics deliver substantial savings through installation efficiency and long-term performance. On a recent highway project, the construction team reported that Haoyang's Non Woven Geotech Fabric was easier to handle and cut than brittle alternatives, reducing installation time by nearly 15%. This labor savings significantly offset the material cost, proving that the cheapest roll isn't always the most economical choice.

The durability of their products, backed by their expertise as a seasoned PET Geotextile China Supplier, prevents costly maintenance and early failure. I've monitored projects where Haoyang's fabric has performed flawlessly for over a decade, while cheaper alternatives required replacement within five years. Furthermore, their specialization as a PE Geotextile China Manufacture ensures optimal product selection for specific chemical environments, preventing premature degradation. When you calculate the extended service life and reduced maintenance, the value proposition of their Non Woven Geotech Fabric becomes undeniable, making the Non Woven Geotextile Price a smart investment in project longevity.

Selecting the right Non Woven Geotech Fabric requires looking beyond basic specifications. Haoyang Environmental Technology delivers excellence through superior polymer selection, engineered needle-punched structure, and demonstrable long-term value. While the Non Woven Geotextile Fabric Price is always a consideration, the performance benefits—from easier installation to extended service life—provide genuine cost efficiency. Their comprehensive capabilities as a Non Woven Geotextile Filter Fabric for Landfill China Supplier, alongside their expertise in both PET Geotextile China Manufacture and PE Geotextile China Supplier roles, make them a single-source solution for diverse project requirements. For engineers and contractors who value performance over mere price points, Haoyang's fabric represents the intelligent choice for sustainable construction.