Product Introduction:

Haoyang Environmental's advanced safety solution combines aluminum trihydrate (ATH)-enhanced bentonite with fire-resistant geotextiles, achieving ASTM E84 Class A flame spread rating (FSI≤25, smoke density≤450) while maintaining ≤10⁻¹¹ m/s water permeability. The 8mm thick composite withstands 2-hour fire resistance tests (EN 1366-4) without structural failure, with the ATH filler releasing bound water at 200°C to actively suppress combustion. Third-party verified to maintain 90% of its waterproofing capacity after thermal cycling (50 cycles of 200°C heating/cooling), this system provides critical protection for subway tunnels and underground utilities where both fire safety and waterproofing are paramount.

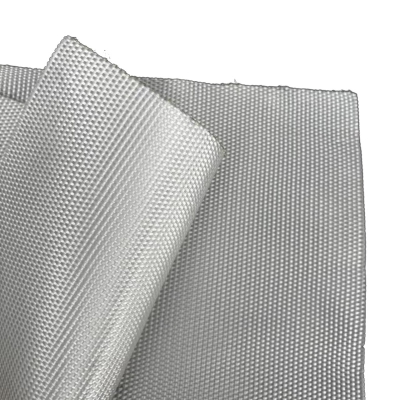

Our high-performance blanket features a 4.8kg/m² sodium bentonite core mechanically bonded between two 300g/m² polypropylene geotextiles through precision needle-punching (220 punches/cm²). This construction delivers 18kN/m tensile strength (ASTM D4595) while allowing 12% elongation before bentonite layer disruption, accommodating structural movements in dynamic environments. The pre-activated formulation achieves ≤10⁻¹² m/s permeability within 8 hours of hydration (vs. 24-48 hours for conventional GCLs), with field data showing 100% self-sealing of 15mm cracks in concrete substrates.

![Needle-Punched Bentonite Waterproofing Blanket Needle-Punched Bentonite Waterproofing Blanket]()

Product Features:

1. Capping Systems - Multi-layer geosynthetic systems remediate contaminated sites by isolating pollutants from the environment.

2. Vegetated Roofs - Lightweight drainage composites support plant growth while managing stormwater runoff on green roofs.

3. Channel Linings - Abrasion-resistant geomembranes protect irrigation channels and flood control systems from water erosion.

Engineered Solutions

1. Environmental Capping Systems:

Triple-layer composites with HDPE geomembrane/bentonite/geotextile.

VOC-resistant formulations for hydrocarbon containment.

0.75mm thick textured surfaces for enhanced interface friction.

2. Urban Green Infrastructure:

25mm thick drainage panels (1.2kg/m²) reduce roof loads by 35%.

PH-balanced (6.5-7.5) root-friendly compositions.

Integrated moisture reservoirs sustain vegetation for 60 days drought.

3. Hydraulic Erosion Control:

2.5mm thick PVC liners with 500% abrasion resistance (ASTM D4886).

UV-stabilized for 25-year exposed service life.

Fish-safe NSF 61 certified options for aquatic habitats.

Quality Assurance:

1. Every-roll spark testing at 20kV (5mm resolution).

2. Batch-wise combustion testing (cone calorimeter per ISO 5660).

3. 1000-hour immersion testing in aggressive leachates.

4. Blockchain-tracked production documentation.

Technical Services:

1. Site-specific fire resistance modeling.

2. Hydraulic performance simulations.

3. Installation crew certification programs.

4. Lifetime maintenance planning.

Project Specifications:

1. Standard fire-retardant thicknesses: 6mm/8mm/10mm.

2. Custom colors for architectural integration (RAL matching).

3. Conductive versions for spark testing compatibility.

4. RFID tags for quality traceability.

Company's Profile:

Haoyang Environmental delivers comprehensive geosynthetic solutions through vertically integrated capabilities spanning material formulation, precision manufacturing, and field engineering support. Our 160,000m² production facility features computer-controlled needle-punching lines capable of producing 5m wide bentonite blankets with ±3% weight uniformity, complemented by Europe's most advanced geomembrane extrusion equipment for seamless 9m wide fire-retardant membranes. The company's engineering team provides full project lifecycle support, from CAD-based system design and finite element analysis to on-site welding supervision and long-term performance monitoring, with documented installations in 38 countries across extreme environments from Arctic oilfields to tropical megacity infrastructures.

![Needle-Punched Bentonite Waterproofing Blanket Needle-Punched Bentonite Waterproofing Blanket]()