Introduction:

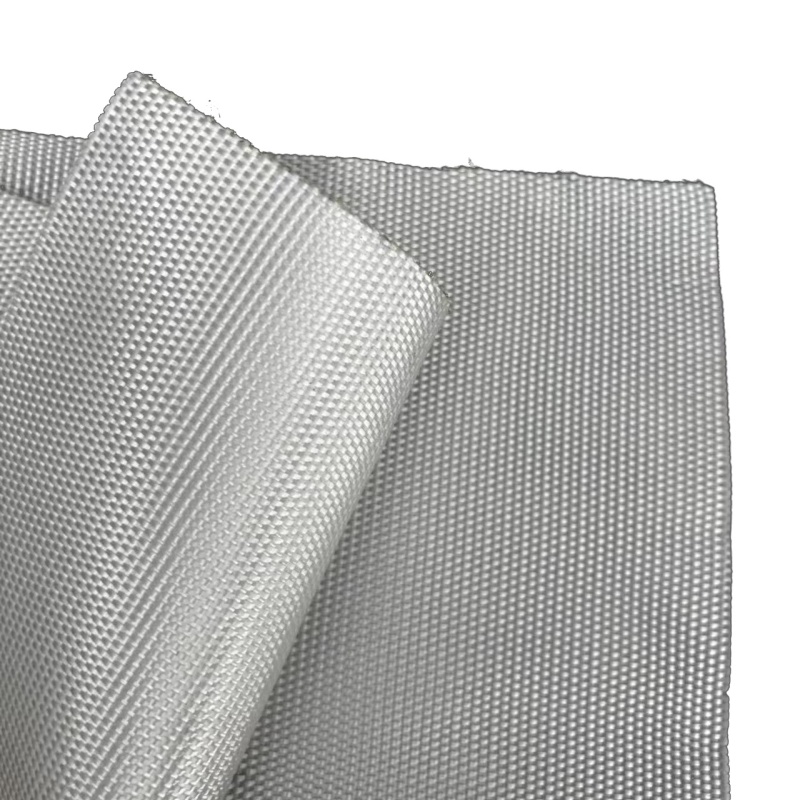

Engineered for superior performance, our High-Flow Filtration Geotextile Filter represents the pinnacle of drainage technology in modern civil engineering. This advanced filtration fabric combines exceptional flow capacity with precise particle retention, making it ideal for critical infrastructure projects. Manufactured from premium UV-stabilized polypropylene, our geotextile filter delivers unmatched durability in demanding environments from landfill liners to coastal protection systems. With specialized needle-punching technology, we achieve optimal porosity (120+ L/m²/s) while maintaining strict AOS (Apparent Opening Size) control for effective soil retention. The product has become the preferred choice for engineers worldwide, with over 500,000 square meters shipped annually to major infrastructure projects across three continents.

![High-Flow Filtration Geotextile Filter High-Flow Filtration Geotextile Filter]()

Key Features

1. Superior Hydraulic Performance:

Our proprietary manufacturing process creates a three-dimensional fiber matrix that maintains exceptional flow rates (120+ L/m²/s) even under heavy loads, outperforming conventional geotextiles by 40-60%. The optimized pore structure prevents clogging while effectively retaining soil particles as small as 0.075mm.

2. Engineered Durability:

The UV-stabilized polypropylene fibers provide outstanding resistance to environmental degradation, with tensile strength maintained at ≥8 kN/m after accelerated aging tests. Special needle-punching technology enhances dimensional stability, preventing fabric distortion during installation.

3. Adaptive Filtration:

Precisely controlled AOS ratings (70-100) ensure optimal performance across various soil types, from coarse sands to silty clays. The gradient density structure automatically adjusts to different hydraulic gradients, maintaining filtration efficiency throughout the project lifespan.

Technical Specifications:

Specification

| Parameter |

Material Composition | 100% Polypropylene |

Fabric Type | Needle-punched nonwoven |

Weight Range | 100g-300g/㎡ |

Roll Width | 4-6 meters (customizable) |

Tensile Strength | ≥ 8 kN/m (MD & CD) |

Permeability | 120-150 L/㎡/sec |

UV Resistance | ≥ 70% retention after 500 hrs |

pH Resistance | 2 - 13 |

Temperature Range | -40°C to +80°C |

Application

Transportation Infrastructure: Used as a stabilizing layer beneath highways and railways to prevent soil erosion while maintaining superior drainage performance (120+ L/m²/s permeability).

Landfill Engineering: Serves as critical filtration media in leachate collection systems, combining high-flow capacity with precise particle retention (AOS 70-100).

Hydraulic Structures: Applied in coastal protection and reservoir projects for erosion control and water filtration.

Urban Development: Utilized in green infrastructure including rooftop gardens and underground drainage systems.

Industrial Applications: Essential for mining operations and agricultural drainage with exceptional chemical resistance.

![High-Flow Filtration Geotextile Filter High-Flow Filtration Geotextile Filter]()

![High-Flow Filtration Geotextile Filter High-Flow Filtration Geotextile Filter]()

Packaging & Shipping

Standard packaging: 150m² per roll, shrink-wrapped with protective ends

Palletized for safe ocean freight (20 rolls/pallet)

Expedited air shipping available

Custom packaging solutions for special projects

Company Capabilities

20,000m² production facility

ISO 9001 certified manufacturing

In-house R&D laboratory

Automated quality control systems

Company’s Strength:

Since 2008, Haoyang Environmental Technology Co., Ltd. has been a leading innovator in high-performance geosynthetic solutions, specializing in drainage, filtration, and containment systems for global infrastructure projects.

![High-Flow Filtration Geotextile Filter High-Flow Filtration Geotextile Filter]()

![High-Flow Filtration Geotextile Filter High-Flow Filtration Geotextile Filter]()