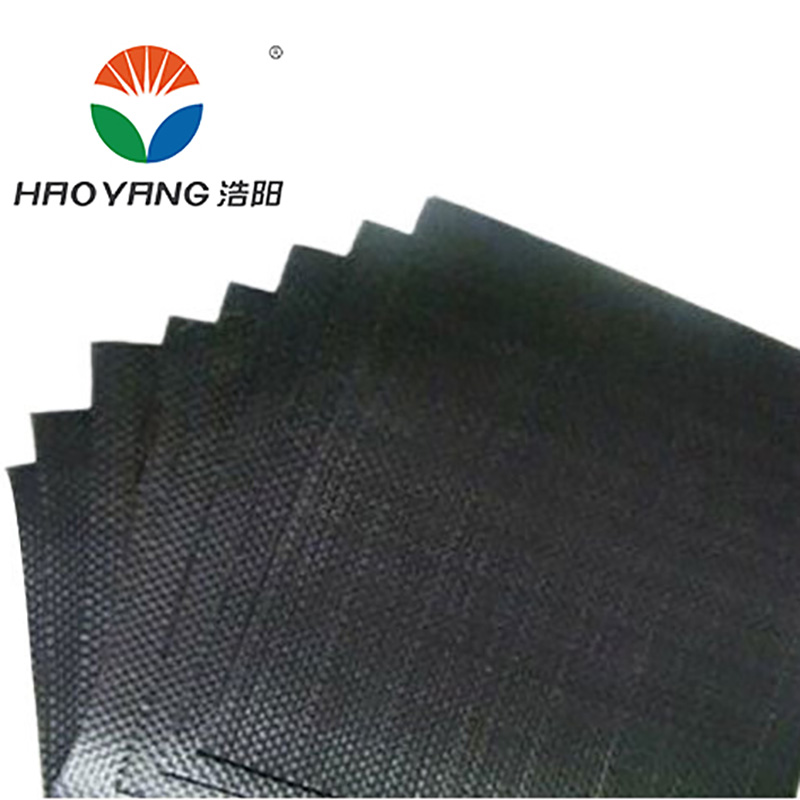

Polyester Filament Woven Geotextile Product Introduction

Overview

The Polyester Filament Woven Geotextile is a crucial component in railway infrastructure, specifically engineered to address the challenges related to track stability. Positioned strategically between the subsoil and the ballast layer, this geotextile serves as a vital barrier. Its primary function is to prevent the migration of fine particles from the subsoil into the ballast. In railway systems, the movement of these fine particles can lead to a variety of issues, including uneven track settlement, reduced load-bearing capacity, and increased wear and tear on the tracks. By effectively halting this particle migration, the geotextile plays a pivotal role in maintaining the overall integrity of the railway track.

The benefits of using this geotextile extend beyond just track integrity. By keeping the track in optimal condition, it significantly reduces the frequency of maintenance activities required. Railway operators often face the costly and time-consuming task of addressing issues caused by particle migration, such as track realignment and ballast replacement. With the Polyester Filament Woven Geotextile in place, these maintenance needs are minimized, leading to substantial cost savings. Additionally, the extended lifespan of the railbed provided by the geotextile means that railway infrastructure can remain operational for longer periods without the need for major overhauls, further enhancing the economic viability of railway systems.

![Polyester Filament Woven Geotextile Polyester Filament Woven Geotextile]()

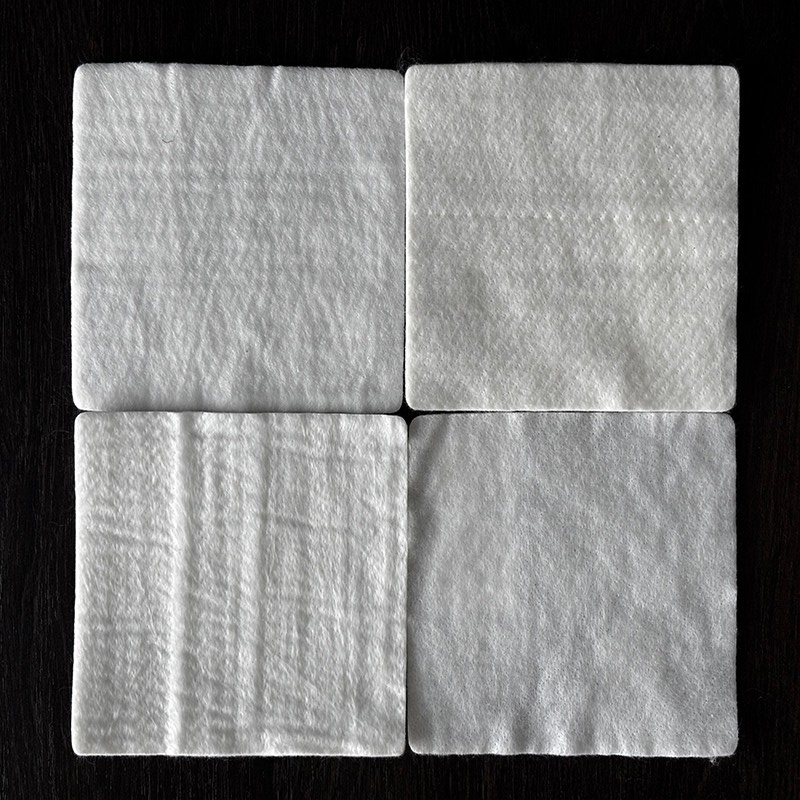

Product Features

High Tensile Strength (up to 800 kN/m) for Heavy-Load Applications

One of the most outstanding features of the Polyester Filament Woven Geotextile is its exceptional high tensile strength, which can reach up to an impressive 800 kN/m. This remarkable strength makes it perfectly suited for heavy-load applications, such as high-speed rail lines and freight railways. Trains, especially those carrying heavy cargo, exert significant forces on the tracks. The geotextile's high tensile strength allows it to withstand these substantial loads without succumbing to breakage or deformation. This not only ensures that the geotextile continues to perform its essential function of separating the subsoil and ballast but also contributes to the overall stability and safety of the railway track. It provides a reliable and durable foundation that can support the weight of trains traveling at high speeds or carrying heavy freight, reducing the risk of track failures and ensuring smooth train operations.

Elongation at Break >50% to Accommodate Ground Movement without Tearing

The geotextile exhibits an impressive elongation at break of more than 50%. This characteristic is of utmost importance in railway environments, where ground movement is an inevitable factor. Factors such as temperature fluctuations, soil compaction, and seismic activity can cause the ground beneath the railway tracks to shift or settle. The geotextile's ability to stretch by more than 50% without tearing allows it to adapt to these ground movements effectively. When the ground moves, the geotextile can deform and accommodate the changes without losing its structural integrity. This ensures that the barrier between the subsoil and ballast remains intact, preventing any potential particle migration that could be triggered by the ground movement. By maintaining its continuous and effective separation function, the geotextile helps to safeguard the stability of the railway track, even in the face of changing ground conditions.

Puncture Resistance (ASTM D4833) to Withstand Sharp Rocks and Debris

The Polyester Filament Woven Geotextile is designed with excellent puncture resistance, as determined by the ASTM D4833 standard. In railway construction and operation, the presence of sharp rocks, construction debris, or other pointed objects in the subsoil or ballast is quite common. These sharp elements can pose a significant threat to the integrity of the geotextile. However, the geotextile's puncture-resistant property enables it to endure contact with such objects without developing holes or tears. By maintaining its physical integrity in the presence of sharp rocks and debris, the geotextile continues to effectively prevent the migration of fine particles, ensuring that the railway track remains protected. This puncture resistance is a crucial feature that enhances the durability and longevity of the geotextile, reducing the likelihood of damage-related maintenance issues and ensuring the long-term performance of the railway infrastructure.

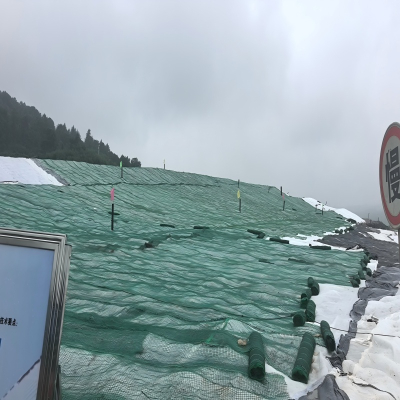

Product Applications

Railway Track Construction and Maintenance

The primary application of the Polyester Filament Woven Geotextile is in railway track construction and maintenance. During the construction phase, it is laid between the prepared subsoil and the ballast layer to create a stable and durable foundation for the tracks. In new railway line projects, this geotextile helps to ensure that the track is built on a solid base, reducing the risk of future settlement and deformation. For existing railway tracks, it can be used during maintenance operations to address issues related to particle migration and track instability. By installing the geotextile, railway operators can restore the integrity of the track and extend its lifespan, reducing the need for costly track replacements.

Other Transportation Infrastructure Projects

In addition to railway tracks, the Polyester Filament Woven Geotextile can also be applied in other transportation infrastructure projects. For example, it can be used in the construction of tramways, light rail systems, and industrial railroads. In these applications, the geotextile serves the same essential functions of separating the subsoil and ballast, preventing particle migration, and providing reinforcement to the track structure. Its high tensile strength, elongation at break, and puncture resistance make it a reliable choice for ensuring the stability and durability of these transportation infrastructure projects, even under heavy loads and varying environmental conditions.

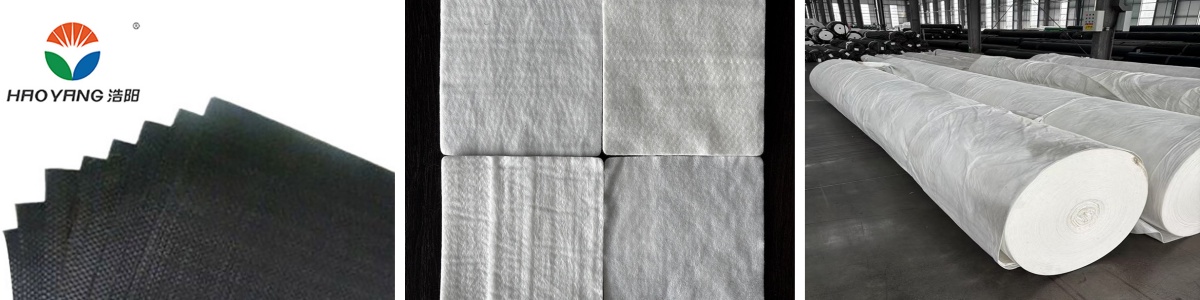

Quality Assurance

Haoyang Environmental Technology (Shandong) Co., Ltd. is committed to upholding the highest quality standards for the Polyester Filament Woven Geotextile. The quality control process commences with the meticulous selection of raw materials. Only premium-grade polyester filaments, sourced from trusted suppliers, are chosen for the production of the geotextile. These raw materials undergo rigorous testing to verify their strength, durability, and chemical properties, ensuring that they meet the company's stringent requirements.

During the manufacturing process, state-of-the-art production equipment and advanced weaving techniques are employed. Every step of the production, from the spinning of the polyester filaments to the weaving of the fabric, is closely monitored to ensure consistency and precision. Quality control checks are carried out at regular intervals to detect and address any potential issues promptly. Advanced testing equipment is used to measure parameters such as tensile strength, elongation at break, and puncture resistance, ensuring that the geotextile meets or exceeds the specified product standards.

After production, the geotextile undergoes a comprehensive final inspection. This includes a visual inspection to check for any visible defects, as well as additional performance tests to verify its suitability for use in railway infrastructure. Only geotextiles that pass all these rigorous quality control measures are approved for distribution, ensuring that customers receive a product of the highest quality and reliability.

Technical Services

The technical team at Haoyang Environmental Technology provides comprehensive support throughout the project lifecycle of the Polyester Filament Woven Geotextile. In the pre-project planning stage, they work closely with clients, including railway engineers, contractors, and infrastructure developers. The team conducts in-depth site surveys to assess the specific conditions of the railway project, such as the type of subsoil, expected traffic loads, and environmental factors. Based on this information, they provide detailed product selection advice, recommending the most suitable specifications of the geotextile for the project. They also offer customized design solutions, taking into account the unique requirements of the railway infrastructure, to ensure optimal performance of the geotextile.

During the installation phase, the company's experienced technicians are dispatched to the project site to provide on-site guidance and training. They ensure that the installation teams are well-versed in the proper handling, cutting, and installation techniques of the geotextile. The technicians oversee the installation process to ensure that it is carried out in accordance with the recommended procedures and industry best practices. They also provide practical advice on how to address any challenges or issues that may arise during installation, such as dealing with uneven subsoil or difficult terrain, to ensure a smooth and successful installation.

Post-installation, the technical team continues to offer support to clients. Regular site visits are conducted to monitor the performance of the geotextile. If any issues are identified, such as signs of damage, reduced effectiveness, or unexpected behavior, the team responds promptly. They conduct detailed investigations to determine the root cause of the problem and provide effective solutions. The team also offers maintenance recommendations to help clients extend the lifespan of the geotextile, such as regular inspections, cleaning, and repairs. By providing comprehensive technical services, Haoyang Environmental Technology ensures that clients can maximize the benefits of the Polyester Filament Woven Geotextile and achieve the long-term success of their railway infrastructure projects.

Business Strength

Haoyang Environmental Technology (Shandong) Co., Ltd.'s acquisition of the CE certification is a significant business strength that highlights the company's commitment to meeting international quality and safety standards. The CE certification is a mark of quality that indicates the company's products, including the Polyester Filament Woven Geotextile, comply with the essential requirements of European Union directives. This certification not only opens up the European market for the company but also enhances its reputation globally as a reliable and trustworthy supplier of geosynthetic products.

The CE certification also demonstrates the company's ability to maintain strict quality control measures throughout the production process. It gives customers confidence in the performance and reliability of the geotextile, knowing that it has undergone rigorous testing and meets the highest standards. This competitive advantage allows Haoyang Environmental Technology to differentiate itself from other suppliers in the market and attract a wider range of customers, both in Europe and internationally. The company's commitment to quality, as evidenced by the CE certification, positions it as a leading provider of geosynthetic solutions for railway infrastructure and other civil engineering projects.

![Polyester Filament Woven Geotextile Polyester Filament Woven Geotextile]()