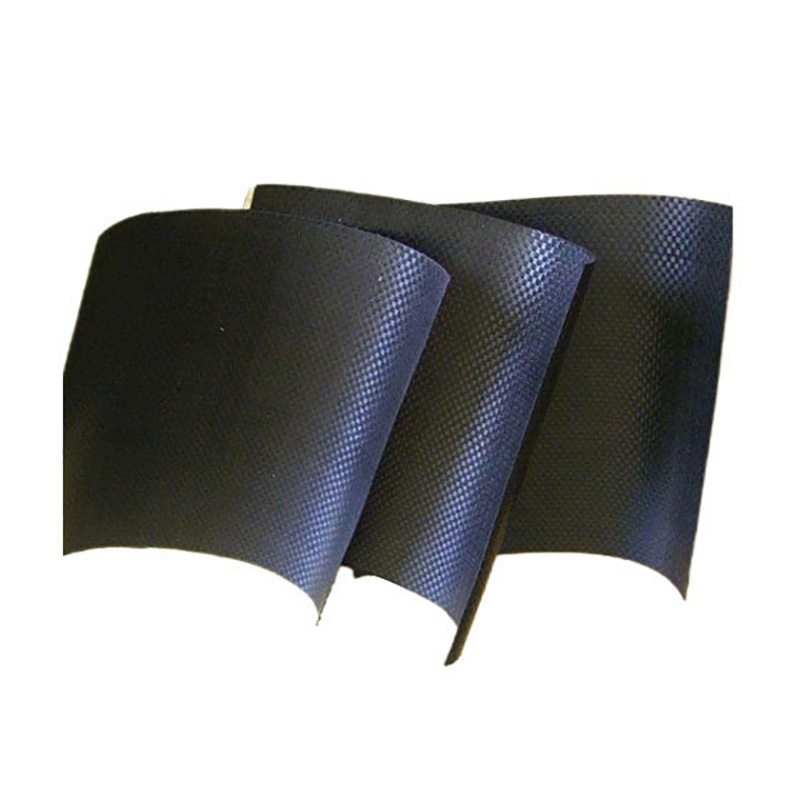

Composite Geotextile Product Introduction

Overview

The Composite Geotextile is a highly functional geosynthetic material engineered to address critical challenges in civil engineering projects, particularly in retaining wall applications. Its primary function is to distribute lateral earth pressures evenly behind walls. In structures like retaining walls, the pressure exerted by the soil can create significant stress on the wall, potentially leading to structural failures over time. By evenly spreading these lateral pressures, the Composite Geotextile helps to reduce stress on the structures, enhancing their stability and longevity.

This geotextile is also highly versatile, being fully compatible with both modular block and gabion systems. When used in conjunction with modular block systems, it reinforces the connection between the blocks, contributing to the overall stability of the wall. In gabion systems, which are often used in erosion control and retaining wall applications, the Composite Geotextile further enhances the structural integrity by evenly distributing the load and preventing soil movement, thus providing an additional layer of protection and stability.

![Composite Geotextile Composite Geotextile]()

Product Features

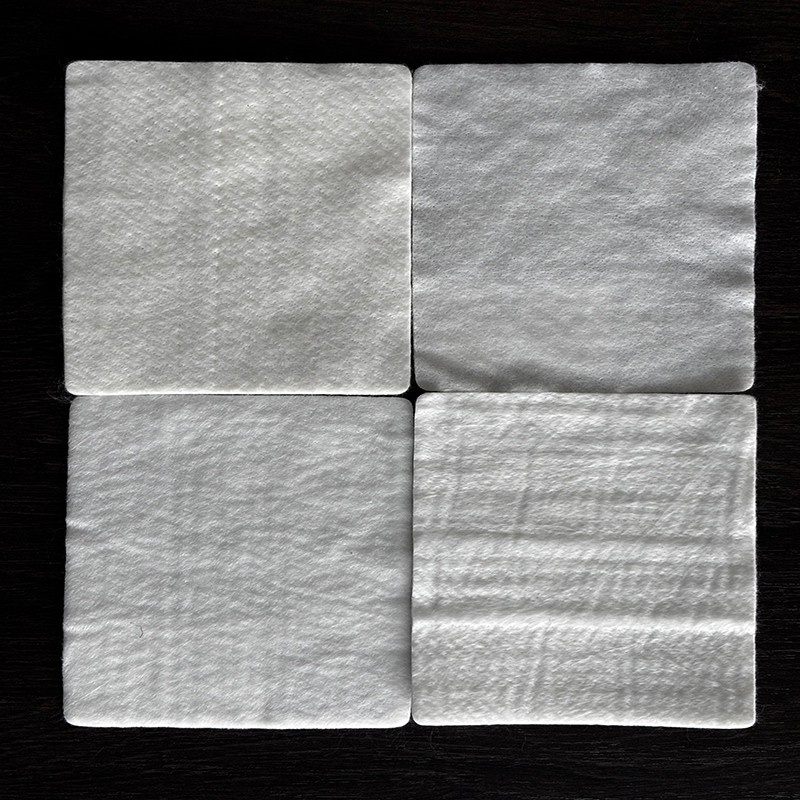

Needle-punched nonwoven structure for superior filtration and soil retention

The Composite Geotextile features a needle-punched nonwoven structure, which is a key factor in its exceptional performance. This structure creates a complex network of fibers that offers superior filtration capabilities. It allows water to pass through while effectively retaining soil particles, preventing soil erosion and maintaining the integrity of the soil structure. In applications such as drainage systems or behind retaining walls, this filtration and soil retention property is crucial. It ensures that the soil remains in place, preventing it from clogging drainage channels and maintaining the stability of the surrounding area.

Spunbond polypropylene fabric with consistent fiber distribution for uniform strength

Constructed from spunbond polypropylene fabric, the Composite Geotextile benefits from a consistent fiber distribution. This even distribution of fibers results in uniform strength across the entire geotextile. Whether it's resisting tensile forces, bearing loads, or withstanding mechanical stress, the geotextile performs consistently throughout its surface. This uniform strength is essential for reliable performance in various civil engineering applications, as it ensures that the geotextile can handle the stresses placed on it without developing weak points or areas of failure.

UV-stabilized polymers to resist degradation under prolonged sunlight exposure

The use of UV-stabilized polymers in the Composite Geotextile is a significant advantage, especially for outdoor applications. Prolonged exposure to sunlight can cause many materials to degrade over time, losing their strength and functionality. However, the UV-stabilized polymers in this geotextile are designed to resist such degradation. They protect the geotextile from the harmful effects of ultraviolet radiation, ensuring that it maintains its physical and mechanical properties even after long-term exposure to sunlight. This feature makes the Composite Geotextile suitable for a wide range of outdoor projects, such as slope stabilization, road construction, and coastal protection, where it will be exposed to the elements for extended periods.

Product Applications

Retaining Wall Construction

As previously mentioned, the Composite Geotextile is an ideal choice for retaining wall construction. Whether it's a small residential retaining wall or a large-scale commercial one, the geotextile's ability to distribute lateral earth pressures and enhance stability is invaluable. In modular block retaining walls, it acts as a reinforcement layer between the blocks, improving the wall's load-bearing capacity and resistance to soil movement. In gabion retaining walls, it helps to prevent the gabions from shifting or deforming under the pressure of the soil, ensuring the long-term integrity of the structure.

Road and Railway Subgrades

In road and railway construction, the Composite Geotextile can be used in subgrades to improve soil stability. It separates different soil layers, preventing the mixing of fine and coarse-grained soils, which can lead to uneven settlement. The geotextile's filtration properties also help to facilitate proper drainage in the subgrade, reducing the risk of waterlogging and the associated weakening of the soil. By providing uniform strength and stability, it contributes to the durability and performance of the road or railway infrastructure, reducing the need for frequent maintenance and repairs.

Erosion Control

For erosion control projects, such as on slopes, riverbanks, or coastal areas, the Composite Geotextile plays a vital role. Its needle-punched nonwoven structure effectively retains soil particles, preventing them from being washed away by water or wind. The geotextile can be used in combination with vegetation to enhance erosion control. As plants grow through the geotextile, their roots further stabilize the soil, creating a more sustainable erosion control solution. Additionally, the UV-stabilized polymers ensure that the geotextile remains effective in outdoor erosion control applications, even in harsh environmental conditions.

Quality Assurance

Haoyang Environmental Technology (Shandong) Co., Ltd. is committed to delivering high-quality Composite Geotextiles, and its adherence to international standards is a testament to this commitment. The company strictly complies with ISO 9001, which is an internationally recognized quality management system standard. This compliance ensures that every aspect of the production process, from raw material sourcing to final product inspection, is carefully controlled and documented, guaranteeing consistent product quality.

In addition, the company adheres to GRI-GM13, which is a standard specific to geomembranes and related products. This ensures that the Composite Geotextile meets the industry's requirements for performance, durability, and environmental compatibility. By following ASTM standards, the company also ensures that its products are tested and evaluated using internationally accepted methods, validating the geotextile's mechanical properties, filtration efficiency, and other critical performance indicators. These quality assurance measures give customers confidence in the reliability and effectiveness of the Composite Geotextile for their projects.

Technical Services

The technical team at Haoyang Environmental Technology offers comprehensive support throughout the project lifecycle. During the project planning stage, they work closely with clients to understand their specific needs, site conditions, and project requirements. Based on this information, they provide detailed product selection advice, customized design solutions, and technical specifications tailored to each project. Whether it's determining the appropriate thickness, strength, or type of Composite Geotextile for a particular application, the team's expertise ensures that clients make informed decisions.

For on-site installation, the company's experienced technicians are available to provide guidance and training. They ensure that the installation teams are well-versed in the proper handling, cutting, and installation techniques of the geotextile. The technicians can also oversee the installation process to ensure that it is carried out in accordance with the recommended procedures and industry best practices, maximizing the performance and lifespan of the geotextile.

Post-installation, the technical team offers continuous support. They conduct regular inspections to monitor the performance of the geotextile and provide maintenance recommendations as needed. In the event of any issues or concerns, the team responds promptly, providing solutions and assistance to ensure the long-term success of the project. This comprehensive technical service approach reflects the company's dedication to customer satisfaction and the successful implementation of projects using the Composite Geotextile.

Business Strength

Haoyang Environmental Technology (Shandong) Co., Ltd.'s ability to comply with multiple international standards is a significant business strength. It showcases the company's commitment to quality, innovation, and meeting the highest industry benchmarks. By adhering to ISO 9001, GRI-GM13, and ASTM, the company can produce Composite Geotextiles that are not only reliable but also competitive in the global market.

This compliance also instills trust in customers, both domestic and international, who know that they are purchasing a product that has been rigorously tested and meets international quality and performance requirements. It positions the company as a reliable partner for various civil engineering projects, from small-scale local initiatives to large, complex international developments. The company's focus on quality assurance and its ability to meet international standards further solidify its reputation as a leading provider of geosynthetic materials in the industry.

![Composite Geotextile Composite Geotextile]()