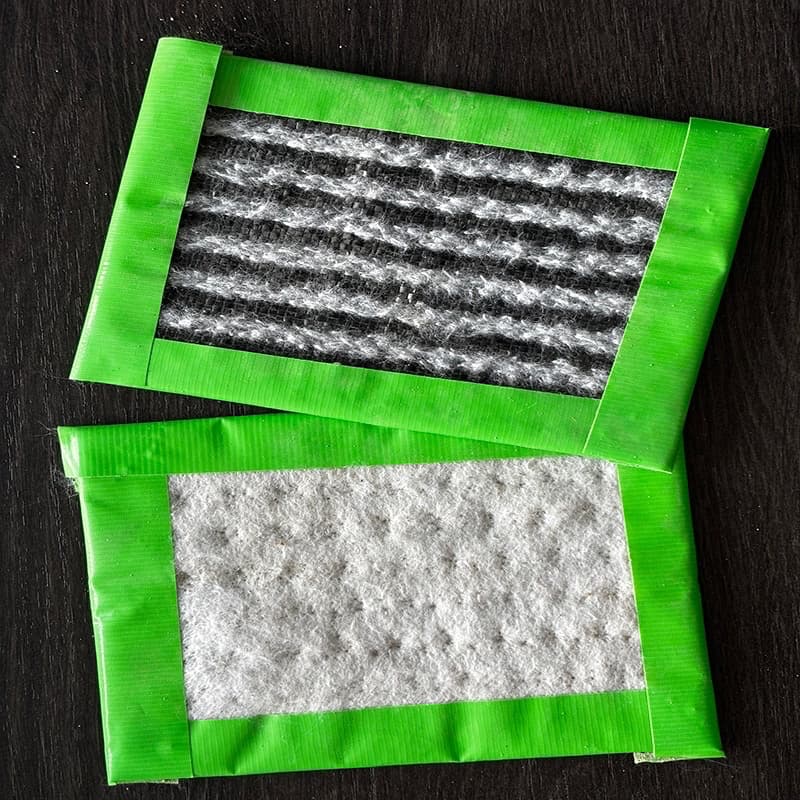

Product Introduction:

Haoyang Environmental's innovative hydrocarbon-resistant containment solution features a specially modified bentonite core that actively repels oils while maintaining superior water-sealing capabilities. The advanced organoclay formulation demonstrates <5% swell reduction after 90-day hydrocarbon exposure (ASTM D5890 modified test), coupled with a consistent 10N/50mm peel strength (EN 12316-1) between the bentonite layer and protective geotextiles. This engineered composite achieves ≤5×10⁻¹⁰ m/s permeability to aqueous solutions while effectively blocking the migration of petroleum-based contaminants, making it ideal for fuel storage facilities and industrial containment applications where mixed fluid resistance is critical.

![Nonwoven Geotextile-Bonded Bentonite Sheet Nonwoven Geotextile-Bonded Bentonite Sheet]()

Product Features:

1. Landfill Caps - Geomembranes and geocomposites create impermeable barriers for final landfill covers, preventing rainwater infiltration and gas emissions.

2. Heap Leach Pads - Chemical-resistant liners contain leaching solutions in metal extraction operations while allowing controlled drainage.

3. Decorative Ponds - Flexible geomembranes provide waterproofing for artificial lakes and water features in landscaping projects.

Engineered Applications

1. Landfill Capping Systems:

Composite barriers combining 1.5mm HDPE geomembranes with drainage geonets reduce leachate generation by 98%.

Methane-resistant formulations prevent gas collection system clogging.

UV-stabilized versions maintain performance for 30+ years in exposed conditions.

2. Mining Heap Leach Pads:

Multi-layer liners withstand pH extremes from 0.5 to 13.5.

Reinforced seams maintain integrity under 2m/s solution application rates.

Embedded leak detection grids provide real-time monitoring capabilities.

3. Landscape Water Features:

Fish-safe polymer formulations (NSF 61 certified).

Root-resistant versions prevent aquatic plant penetration.

Color-matched membranes blend with natural surroundings.

Technical Validation

All products undergo:

1,000-hour immersion testing in hydrocarbon mixtures.

Cyclic wet-dry evaluation per GRI-GCL3.

Large-scale interface shear testing (50kPa normal stress).

Third-party certified hydraulic conductivity verification.

Quality Assurance

Automated optical inspection for thickness uniformity (±0.1mm).

Every roll tested for peel strength and swell index.

Blockchain-tracked production records for full traceability.

Annual third-party audits to ISO 9001 and GRI standards.

Project-Specific Solutions

Available customization includes:

Permeability adjustments from 10⁻⁸ to 10⁻¹² m/s.

Custom roll widths up to 8m for large-scale projects.

Temperature-adapted formulations (-50°C to +120°C).

Conductive versions for leak detection systems.

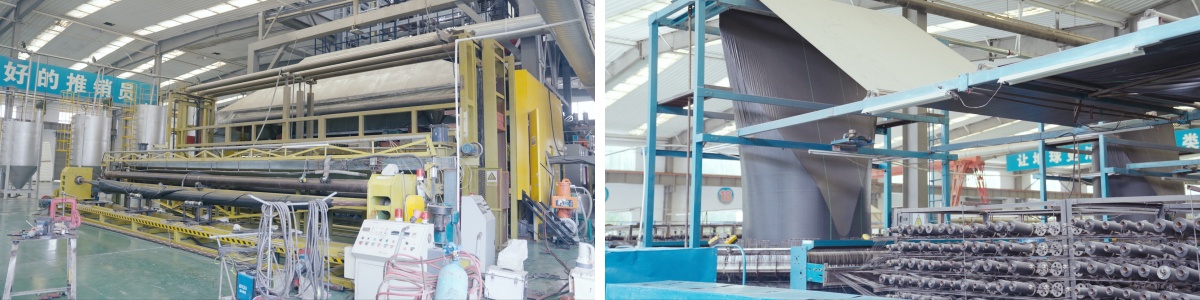

Company's Profile:

Haoyang Environmental has established itself as a global leader in advanced geocomposite solutions through strategic technology partnerships with German engineering firms and continuous investment in material science innovation. Our manufacturing processes combine European precision equipment with rigorous quality control protocols, producing geosynthetics that meet the most demanding project specifications for environmental containment and infrastructure protection. With technical support centers in three continents, we provide engineered solutions for critical applications ranging from hazardous waste isolation to water conservation projects, backed by comprehensive testing data and 20+ years of field performance documentation.

![Nonwoven Geotextile-Bonded Bentonite Sheet Nonwoven Geotextile-Bonded Bentonite Sheet]()