How to Choose Geotextile for Mining: A Comprehensive Guide

The mining enterprise operates in some of the most disturbing environments on earth. From managing big volumes of mixture to controlling erosion on unstable slopes, each operation requires strong and dependable solutions. This is the place the proper Geotextile Fabric turns into a critical, but frequently overlooked, element for safety, efficiency, and environmental compliance. Selecting the unsuitable cloth can lead to catastrophic failures, expensive downtime, and full-size environmental damage.

This information will furnish a targeted framework for deciding on the best geotextile for your mining application, making sure your initiatives are constructed on a stable foundation.

I. Understanding the Core Types: Woven vs. Non-Woven Geotextiles

The first and most vital selection factor is appreciation the vital distinction between the two main classes of geotextiles. Their manufacturing method dictates their bodily homes and, consequently, their perfect applications.

A woven geotextile is manufactured by way of interlacing polypropylene or polyester yarns in a everyday pattern, a good deal like a textile. This technique creates a high-strength, steady cloth with a pretty low elongation. The most frequent kind is PP Woven Geotextile (Polypropylene Woven Geotextile), prized for its exquisite tensile energy and durability.

Key Properties: High tensile strength, low elongation, wonderful load distribution, excessive friction attitude with soils.

Best For: Reinforcement, stabilization, and separation beneath extraordinarily heavy loads. Think get entry to roads for haul trucks, working structures on gentle subgrades, and base reinforcement for tailings dams.

2. Non Woven Geotextile Fabric

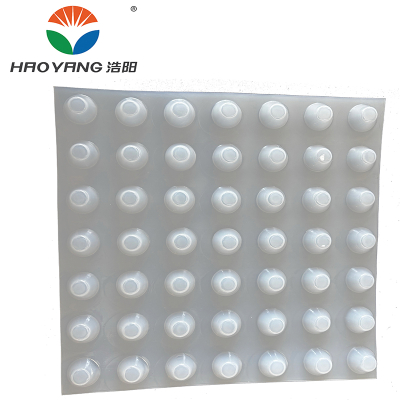

A non woven geotextile cloth is created by using bonding artificial fibers (usually polypropylene) collectively via mechanical (needle-punching), thermal, or chemical means. This effects in a thick, felt-like material that is porous and permits for water to glide freely thru its plane.

Key Properties: High permeability, puncture resistance, filtration capability, and elongation.

Best For: Drainage, filtration, erosion control, and protection. Ideal for use at the back of preserving walls, in drainage ditches, landfill leachate systems, and as a protecting cushion for geomembranes.

Need electricity and stability? Choose a woven geotextile. Need drainage and filtration? A non woven geotextile cloth is possibly the answer. Many complicated projects, like a tailings dam, will use a mixture of both.

II. Matching Function to Application: A Mining-Specific Breakdown

Mining websites are a mosaic of extraordinary challenges. Let’s damage down the most frequent functions and the geotextile specs required for each.

1. Stabilization and Separation for Haul Roads

Unpaved haul roads bearing the weight of 200-ton vehicles are the spine of a mine. They require a material that prevents the mixing of the smooth subgrade with the robust combination base, keeping street integrity.

Recommended Type: A high-strength woven geotextile fabric. Its excessive modulus presents a steady platform that distributes the significant wheel loads, lowering rutting and combination loss.

Key Specs: Look for excessive Grab Tensile Strength (e.g., >1,200 lbs) and excessive Geotextile Polyester or polypropylene selections for most useful long-term performance. A difficult PP Woven Sack with Anti-UV therapy is frequently a economical and sturdy desire for this application, resisting degradation from daylight for the duration of installation.

2. Drainage and Filtration in Tailings Management

Tailings storage amenities (TSFs) are engineered buildings that require particular water management. Geotextiles are used to filter fantastic tailings particles whilst permitting seepage water to escape, stopping the buildup of damaging pore pressure.

Recommended Type: A needle-punched non woven geotextile fabric. Its 3D matrix is best for filtering fines whilst retaining permeability.

Key Specs: Focus on glide price (permittivity), puncture resistance (CBR), and obvious opening dimension (AOS) to make sure compatibility with the unique soil particles. PP Geotextile Non Woven is the trendy right here due to its incredible chemical resistance.

3. Erosion Control on Slopes and Berms

Exposed soil on slopes is surprisingly inclined to erosion from wind and rain, main to sediment runoff and environmental issues. Geotextiles supply immediately floor cowl and assist for vegetation.

Recommended Type: For temporary, speedy stabilization, a light-weight non woven geotextile material is regularly used as a biodegradable blanket. For permanent, high-performance reinforcement on steep slopes, a high-strength woven geotextile or specialised turf reinforcement mat (TRM) is required.

Key Specs: For woven, excessive tensile electricity is key. For non-wovens, weight (e.g., oz/yd² or g/m²) is a frequent indicator of durability.

III. Beyond Type: Key Material and Environmental Considerations

Choosing between woven and non-woven is simply the start. The uncooked polymer and components decide long-term overall performance in harsh mining conditions.

Polymer Type: Geotextile Polyester has best resistance to creep (elongation below sustained load) and UV degradation in contrast to polypropylene. However, PP Woven Geotextile gives first-rate chemical resistance to a huge vary of acids and alkalis many times located in mining environments, making it the most regular choice.

UV Resistance: Geotextiles uncovered to daylight require stabilization additives. Always specify a PP Woven Sack with Anti-UV or dealt with non-woven if the product will be uncovered for extra than a few months earlier than being covered.

Puncture and Abrasion Resistance: During set up and below load, the material need to face up to damage. Look for excessive puncture power (e.g., ASTM D4833) and Elongation properties, which are inherent strengths of a strong non woven geotextile material and extraordinary woven geotextile.

Long-Term Flow (Clogging Resistance): For integral filtration applications, the PP Geotextile Non Woven should be designed to forestall soil particles from clogging its pores over time, a property recognized as anti-clogging performance.

A Systematic Approach to Selection

There is no single "best" geotextile for mining. The most fulfilling preference is a engineered choice based totally on:

Primary Function: Is it separation, reinforcement, filtration, drainage, or protection?

Site-Specific Loads: Understand the mechanical stresses (traffic, overburden pressure, installation).

Environmental Conditions: Consider chemical exposure, UV radiation, and doable for clogging.

Always seek advice from with a certified geotechnical engineer and professional Geotextile Fabric manufacturer. They can furnish technical facts sheets and project-specific guidance, making positive the woven geotextile fabric or non woven geotextile material you select offers you the performance, safety, and sturdiness your mining operation demands. By investing in the suitable geotextile solution, you make investments in the structural integrity and environmental sustainability of your complete project.