Definition and Common Classification of Geomembranes

What is geomembrane?

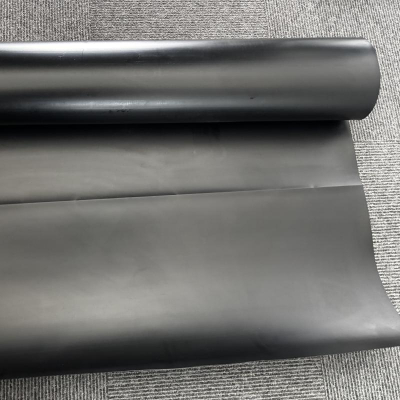

Geomembrane is an anti-seepage membrane that made of virgin resins such as high-density polyethylene (HDPE). It has excellent performance of anti-seepage and chemical corrosion resistance, which can prevent water and other liquids from penetrating into the soil, protect both of groundwater and surface water resources effectively. Therefore, geomembrane usually used as anti-seepage materials in landfills, chemical, mines, reservoirs and other projects. Due to its excellent tensile strength, anti-seepage ability, flexibility, light weight and cost-effectively, it is often used in civil engineering to build warehouses, dams, cofferdams, canals, artificial lakes, reservoirs and other water conservancy projects with extremely high requirements for waterproofing.

The difference between geomembrane and geotextile

Geomembrane completely isolates soil and is not easy to penetrate water. It is often used in water conservancy projects.

Geotextile focuses on water permeability and strengthening the stability of soil, making it difficult to loosen and slide.

Raw materials and manufacturing

Geomembrane is a new type of anti-seepage and anti-corrosion material used for anti-seepage and moisture-proofing. The main component is polyethylene resin (97.5%) with a certain proportion of carbon black masterbatch (about 2.5%), as well as a trace amount of anti-aging agent, antioxidant, UV absorber, stabilizer, etc. blown. The resin used is a virgin polyethylene resin designed and formulated for the application of flexible anti-seepage membranes.

Geomembrane classification

1. Classification by material

HDPE geomembrane: high-density polyethylene (HDPE), it has high strength and corrosion resistance, but poor flexibility, which is often used in the harsh environments such as landfills and chemical waterproofing.

LDPE/LLDPE geomembrane: low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), it has softer texture and stronger deformation resistance, which is suitable for scenes such as artificial lakes and breeding ponds that need to adapt to foundation deformation.

PVC geomembrane: polyvinyl chloride material, containing plasticizer, good ductility and easy to weld, but easy to age after long-term exposure, mostly used for temporary anti-seepage or landscape pools.

EPDM geomembrane: ethylene propylene rubber material, excellent elasticity, strong weather resistance, suitable for roof greening or high-cold area projects, but the cost is relatively high.

TPO geomembrane: thermoplastic polyolefin material, environmentally friendly without plasticizer, UV resistance, mainly used in projects with high environmental protection requirements such as roof waterproofing.

2. Classification by structure

Smooth geomembrane: smooth surface, optimal anti-seepage performance, but low friction coefficient, need to be used with a protective layer.

Rough geomembrane: the surface is specially treated to form a rough texture, which enhances friction with the soil and is suitable for slope anti-seepage projects, such as landfill slopes.

Composite geomembrane: composed of geomembrane and geotextile (non-woven fabric), such as "one cloth and one membrane" or "two cloths and one membrane", with both anti-seepage and protection functions, often used in water conservancy or road projects.

3. Classification by production process

Blown geomembrane: produced by blow molding process, with uniform thickness, suitable for materials such as HDPE and LLDPE.

Calendered geomembrane: roll-formed, suitable for flexible materials such as PVC.

Sprayed geomembrane: on-site spraying construction (such as polyurea), used for complex shapes or repair projects.

4. Classification by special functions

UV-resistant geomembrane: adding anti-aging agents such as carbon black to extend outdoor service life.

Conductive geomembrane: mixed with conductive materials, used in leakage detection systems.

Self-repairing geomembrane: experimental product that can automatically repair tiny cracks.

The difference between HDPE LDPE LLDPE geomembrane

Material Properties

Parameter | HDPE | LDPE | LLDPE |

Density(g/cm³) | 0.940-0.976 | 0.910-0.940 | 0.915-0.935 |

Crystallinity | 80%-90% | 45%-65% | 55%-65% |

Molecular structure | Linear, less branched | Many branches | Linear short chain |

Production process | Low pressure polymerization | High pressure polymerization | Low pressure polymerization |

2. Mechanical Properties

Parameter | HDPE | LDPE | LLDPE |

Tensile strength(MPa) | ≥28 | 10-20 | ≥28 |

Elongation at break (%) | ≥700 | 100-700 | 500-1000 |

Puncture resistance | Excellent (high rigidity) | Poor | Excellent (high toughness) |

Stress cracking resistance | Poor | excellent | excellent |

3. Chemical Stability and Weather Resistance

Parameter | HDPE | LDPE | LLDPE |

Acid and alkali resistance | excellent | good | excellent |

Resistant to organic solvents | excellent | Poor | good |

Anti-ultraviolet aging | Stabilizer required | Better (can be used naked) | better |

Operating temperature range | -70℃ - 110℃ | -70℃ - 90℃ | -90℃ - 94℃ |

4. Summary

HDPE: High strength and high chemical resistance, but poor flexibility, suitable for harsh environments.

LDPE: Soft and easy to construct, but weak mechanical properties and heat resistance, suitable for short-term or low-stress projects.

LLDPE: Combines the strength of HDPE and the toughness of LDPE, with the best tear resistance, suitable for complex foundations.

Application

1. Environmental protection projects: such as landfills, sewage treatment plants, power plant regulating ponds, industrial and hospital solid waste landfills;

2. Water conservancy projects: such as horizontal anti-seepage of river, lake, reservoir, dam and channel projects;

3. Municipal engineering: subway, underground garage projects, roof gardens, sewage pipe anti-seepage;

4. Garden projects: artificial lakes, rivers, golf course reservoirs;

5. Petrochemical: anti-seepage of oil storage tanks in refineries, linings and secondary linings of chemical reaction tanks and sedimentation tanks;

6. Mining: anti-seepage of bottom linings of heap leaching tanks, dissolution tanks, sedimentation tanks and tailings dams;

7. Transportation facilities: foundation reinforcement of highways and anti-seepage of culverts;

8. Agriculture: anti-seepage of reservoirs, drinking water pools, water storage ponds and irrigation systems;

9. Aquaculture: linings of breeding ponds, fish ponds and shrimp ponds, and slope protection of sea cucumber circles;

10. Salt industry: salt field crystallization pools, brine pool covers and salt films.