Introduction

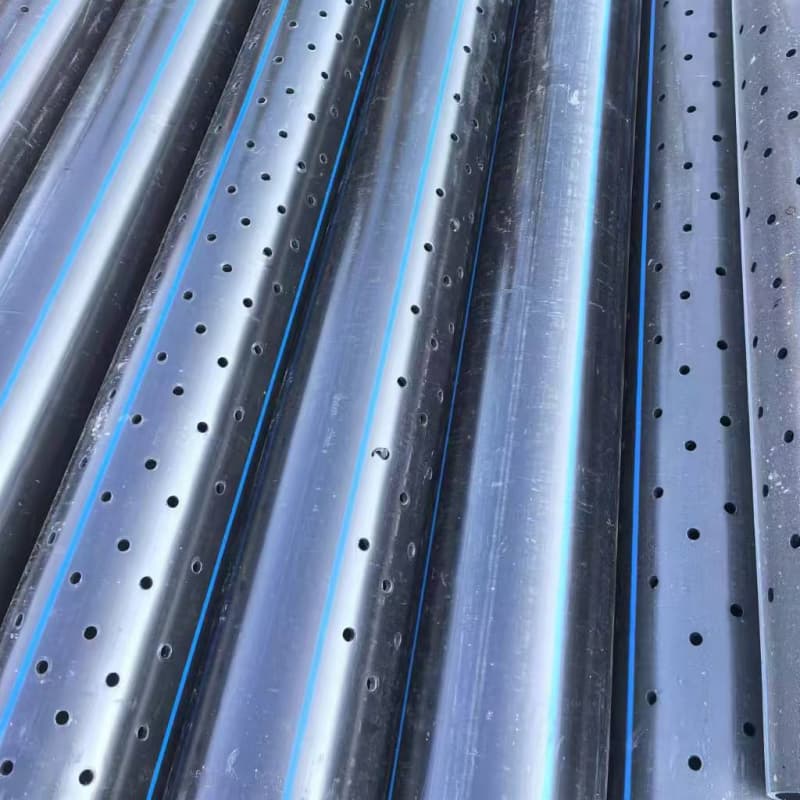

HDPE Pipe represents the pinnacle of present day piping technology, supplying most useful overall performance throughout severa industrial and municipal applications. As a thermoplastic piping solution, HDPE Pipe combines terrific sturdiness with economical installation, making it the fabric of desire for water distribution, fuel transmission, mining operations, and wastewater administration structures worldwide.

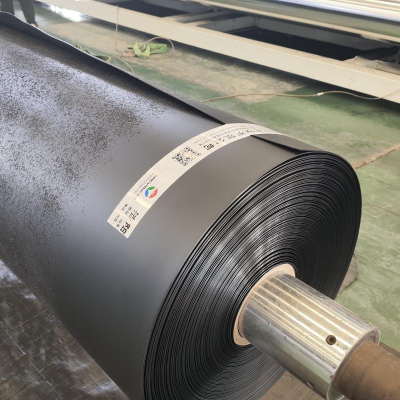

![HDPE Pipe HDPE Pipe]()

Material Composition

The HDPE Pipe is manufactured from premium-grade high-density polyethylene resin (PE100 or PE4710) with specialized additives that enhance:

UV resistance for above-ground applications

Stabilizers for long-term oxidative resistance

Black carbon dispersion for maximum durability

Key Features & Benefits

1. Unmatched Durability

HDPE Pipe offers extraordinary impact resistance, with a minimum service life expectancy of 50 years. The molecular structure of HDPE Pipe provides excellent resistance to:

Chemical corrosion from acids, alkalis, and salts

Abrasion in slurry applications

Biological growth and tuberculation

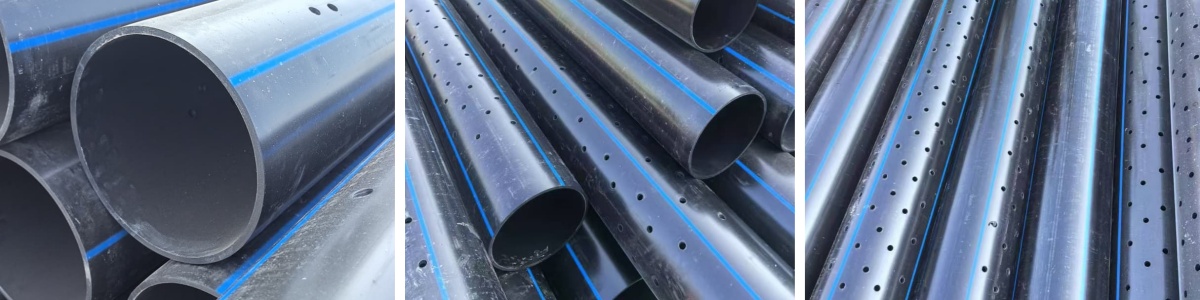

2. Leak-Free Joint Integrity

HDPE Pipe utilizes advanced butt fusion or electrofusion joining methods that create:

Homogeneous, permanent connections

Joints stronger than the pipe itself

Zero-leak performance throughout its service life

3. Lightweight Yet Strong

Despite weighing significantly less than traditional materials, HDPE Pipe maintains:

Pressure ratings up to PN25 (125psi)

Exceptional ring stiffness (SN4-SN16)

Outstanding resistance to slow crack growth

4. Hydraulic Efficiency

The smooth interior surface of HDPE Pipe delivers:

Hazen-Williams C-factor of 150

Reduced pumping energy requirements

Self-cleaning flow characteristics

5. Installation Advantages

HDPE Pipe installation benefits include:

Lower equipment requirements

Faster joining processes

Trenchless installation capabilities (HDD, pipe bursting)

Reduced bedding and backfill needs

6. Environmental Performance

HDPE Pipe is recognized as the most sustainable piping option due to:

Technical Specifications

Property | Test Standard | Performance |

Density | ASTM D1505 | 0.949-0.955 g/cm³ |

Melt Index | ASTM D1238 | ≤0.4 g/10 min |

Tensile Strength | ASTM D638 | ≥20 MPa |

Hydrostatic Design Basis | ASTM D2837 | 1600 psi |

Notched Constant Tensile Load | ISO 16770 | >500 hours |

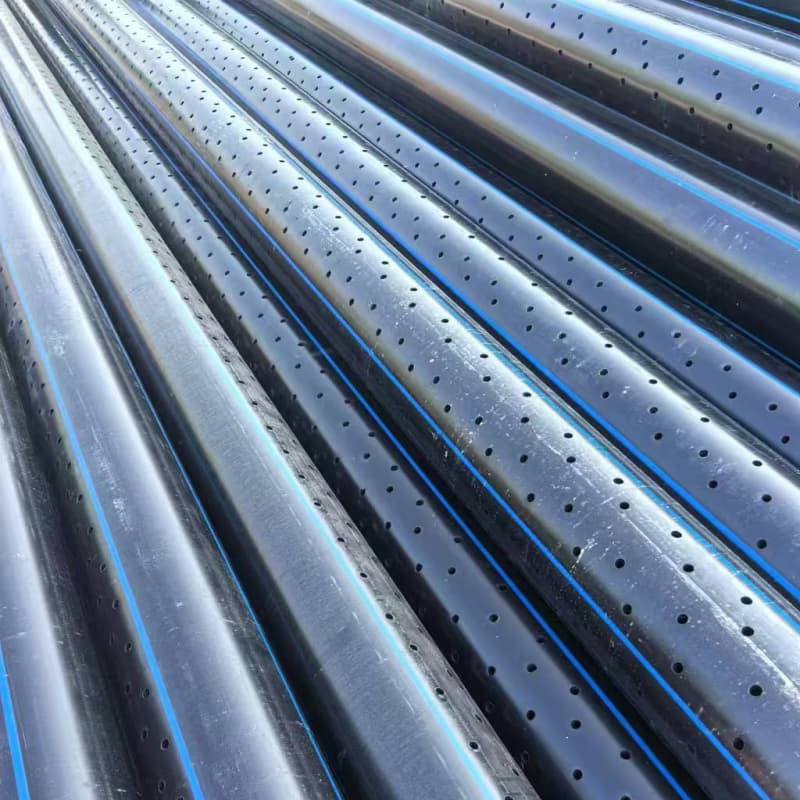

Applications

Water Systems

HDPE Pipe is ideal for:

Potable water distribution

Raw water transmission

Irrigation networks

Desalination plants

![HDPE Pipe HDPE Pipe]()

HDPE Pipe serves critical roles in:

HDPE Pipe excels in:

Sewer force mains

Gravity sewer systems

Stormwater management

Industrial wastewater

Installation Methods

Trenching

HDPE Pipe installation typically requires:

Minimum bedding preparation

Standard pipe zone backfill

Reduced trench widths

Trenchless Technologies

HDPE Pipe is perfect for:

Quality Assurance

Every HDPE Pipe undergoes:

In-process quality control

Hydrostatic testing

Dimensional verification

Fusion procedure qualification

Why Choose HDPE Pipe?

Compared to alternative materials, HDPE Pipe provides:

Lower total installed cost

Reduced maintenance requirements

Superior long-term performance

Minimal environmental impact

Conclusion

HDPE Pipe has revolutionized fluid transport structures with its special aggregate of durability, efficiency, and cost-effectiveness. As infrastructure needs develop increasingly more complex, HDPE Pipe continues to show why it is the favored desire for engineers and utility operators worldwide. Whether for municipal water systems, industrial processes, or gasoline distribution networks, HDPE Pipe supplies dependable overall performance that stands the check of time.

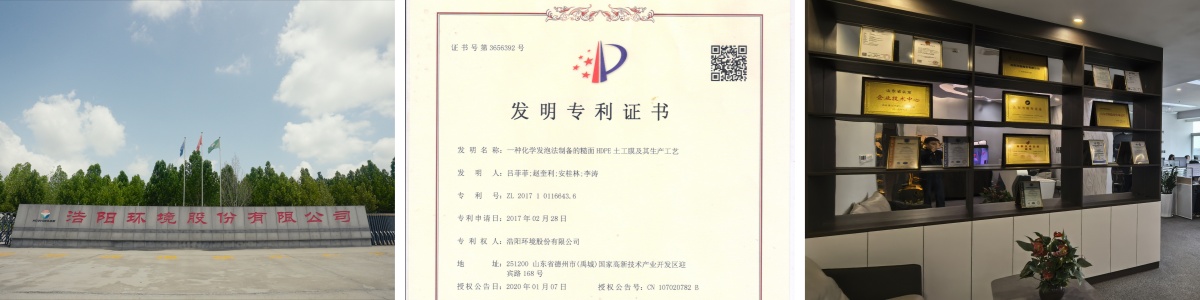

About Us

Since our establishment, we have been a main producer and provider of great HDPE pipes, dedicated to handing over progressive piping options for water supply, gasoline distribution, industrial applications, and infrastructure projects. With years of understanding in polymer engineering and superior manufacturing technologies, we take pleasure in imparting durable, cost-effective, and environmentally pleasant HDPE pipes that meet world enterprise standards.

![HDPE Pipe HDPE Pipe]()