Introduction

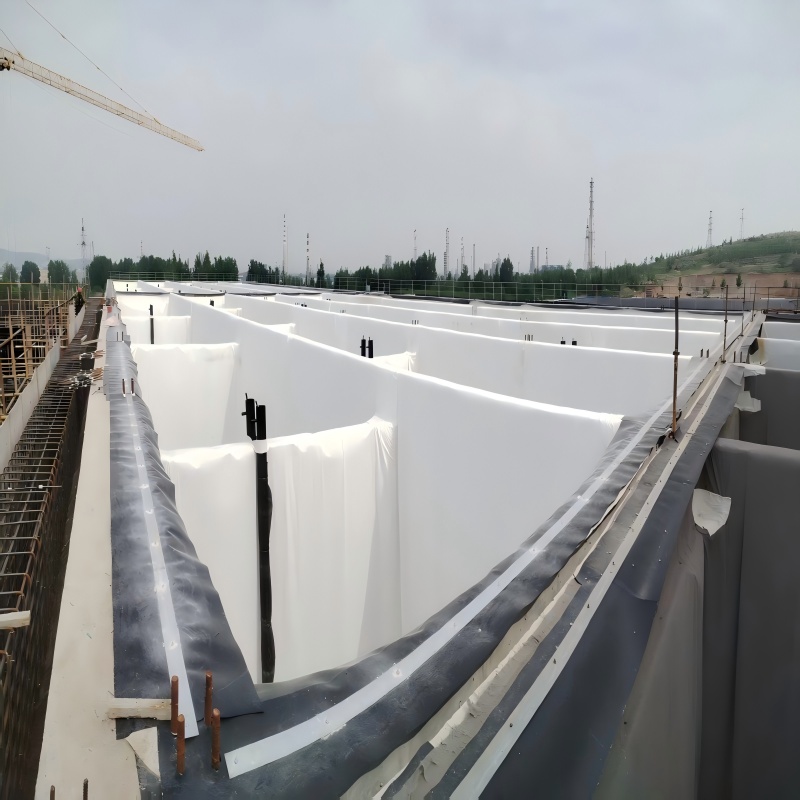

Composite Drainage Geonet is a high-performance drainage material used in civil engineering (especially geotechnical engineering and environmental engineering). It is not a single material, but a "sandwich" structure composed of a core drainage layer and two (or one) side filter protection layers through thermal bonding or needle punching.

![Composite Drainge Geogrid Mesh Composite Drainge Geogrid Mesh]()

Application

1. Landfill: bottom leachate collection layer, top cover drainage layer, slope drainage.

2. Retaining wall and slope drainage: drain water, reduce hydrostatic pressure, and improve slope stability.

3. Tunnel and underground structure drainage: drainage layer behind the lining to prevent water pressure accumulation.

4. Roadbed and pavement drainage: drain water from the roadbed to prevent frost heave and softening, and extend the life of the road.

5. Roof garden and underground garage roof drainage: quickly drain excess water, reduce structural load, and protect the waterproof layer.

6. Sports field, golf course drainage: ensure the site is dried quickly.

7. Drainage under the lining of the pool and channel: drain groundwater pressure and prevent lining uplift damage.

![Composite Drainge Geogrid Mesh Composite Drainge Geogrid Mesh]()

Features

1. High drainage efficiency. Under a pressure of 200kPa, the plane water conductivity is as high as 1×10⁻⁴ ~ 5×10⁻³ m²/s, which is dozens of times the drainage efficiency of the sand and gravel layer of the same thickness. In the landfill, 120L/m² of leachate can be drained per day, while the traditional sand layer is only 2L/m².

2. Strong compressive resistance. The compressive strength is ≥500 kPa under 50% compression deformation. It still maintains >80% of the drainage space under 50 meters of fill load, and almost restores the original thickness after load unloading.

3. Precise anti-clogging design, through O₉₀ ≤ (1~2)×d₈₅ matching geotextile pore size, gradient ratio is less than 3.0, through 30-year accelerated clogging test, the service life in silt environment can exceed 50 years, while the traditional geonet is blocked in 5 years.

Technical Parameter

1. High load environment

Parameters | Requirements | Test Conditions | Remarks |

Compressive Strength | ≥500 kPa at 50% | ISO 25619 | Resistant to hundreds of meters of garbage pile |

Hydraulic Conductivity | ≥2×10⁻⁴ m²/s at 500 kPa | ASTM D4716 | High load still requires efficient drainage of leachate |

Oxidation Induction Time | ≥100 min | ASTM D3895 | Prevent chemical corrosion and aging |

90% Equivalent Pore Size | ≤0.15 mm | - | Anti-fine particle clogging core mesh |

2. Medium load environment

Parameters | Requirements | Test Conditions |

Compressive Strength | 200–400 kPa at 30% compression | ISO 25619 |

Hydraulic Conductivity | ≥5×10⁻⁵ m²/s at 200 kPa | ASTM D4716 |

90% Equivalent Pore Size | 0.15-0.25mm | - |

About Us

Haoyang Environmental Technology Shandong Co Ltd pioneers high performance composite drainage geogrid mesh systems engineered for critical water management challenges since 2008 our advanced three dimensional structural design integrates geonet core with filtration layers delivering superior hydraulic conductivity exceeding 5000 m² day while maintaining 98% void space under extreme loads ideal for landfill leachate collection mining tailings dewatering and tunnel drainage projects globally field validated across tropical Southeast Asia arid African mines and South American highlands these grids replace traditional gravel layers reducing construction costs by 40% and accelerating installation 3x partner with our ISO certified team for custom engineered drainage solutions tailored to your specific soil conditions and regulatory requirements.

![Composite Drainge Geogrid Mesh Composite Drainge Geogrid Mesh]()