Differences Between Woven & Knitted Geotextiles

Woven geotextiles and knitted geotextiles are two different types of geosynthetics,which are widely used in the fields of environmental engineering, civil engineering and other engineerings. Although these two materials have the functions of isolation, filtration, reinforcement, protection and drainage, they are different in structure, mechanical properties, hydraulic properties and suitability for specific applications because of their different manufacturing processes.

Woven geotextiles are produced by traditional looms. Wrap and weft yarns interwoven orthogonally to form a grid-like stable structure.

Knitted geotextiles are manufactured by using specialized machinery, one or more continuous yarns woven into interconnected loops and interwoven in different patterns.

Therefore, it is important to understand their manufacturing characteristics and processes when choosing geotextiles. The selection of the right type of geotextile should be matched to the specific functional requirements and conditions of the project.

Manufacturing Process:

1. Woven geotextile: It is made of two sets of yarns (warp and weft) interwoven vertically at a 90-degree angle on a loom. It is similar to the weaving method of traditional fabrics such as canvas and denim.

2. Knitted geotextile: It is made of one or more yarns interwoven and connected by a series of coils. It is similar to the way a sweater is knitted by hand or machine.

Structural Characteristics:

1. Woven geotextile: The structure is stable and tight, and there is basically no relative movement between the yarns. The pores are usually regular and relatively uniform rectangular or square openings, but their size is controlled by the thickness of the yarn and the weaving density. The pore size is usually large and difficult to control to a small size.

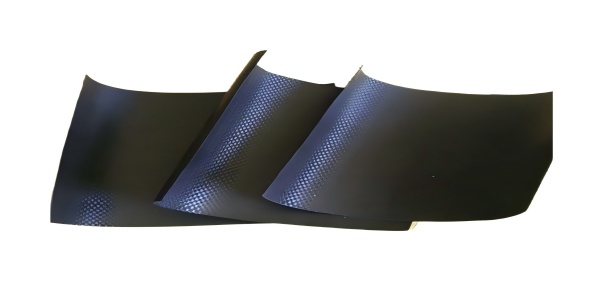

2. Knitted geotextile: The structure is relatively loose and elastic. The coil structure gives the yarn more room to move when it is stressed. The pore shape is irregular, and the size and distribution may not be as uniform as that of woven geotextiles. The pore size can be made relatively small (depending on the yarn fineness and coil density).

Mechanical Properties:

1. Tensile strength:

Woven geotextiles: usually have high initial tensile strength and modulus in both the warp and weft directions (or longitudinal/transverse directions). Its strength mainly comes from the strength of the yarn itself.

2. Knitted geotextiles: Its tensile strength and modulus are usually lower than those of woven geotextiles of the same weight or thickness. Its strength comes from the deformation ability of the roll structure.

Elongation (Deformation Ability):

1. Woven geotextiles: Low elongation. Small deformation when subjected to force, relatively low failure strain. Relatively rigid structure.

2. Knitted geotextiles: High elongation. Can withstand large deformation when subjected to force and is not easy to break, with high failure strain. Has good flexibility and elasticity.

Tear Strength:

1. Woven geotextiles: usually have high tear strength.

2. Knitted geotextiles: Tear strength is usually low. Once the loop breaks, it is easy to "fall apart", causing the crack to expand rapidly.

Bursting Strength:

1. Woven geotextile: The bursting strength is usually higher.

2. Knitted geotextile: The bursting strength is usually lower.

Friction Performance:

1. Woven geotextile: The surface is relatively smooth, and the interface friction angle with the soil may be small.

2. Knitted geotextile: Terry structure

|  |

Knitted Geotextiles | Woven Geotextiles |

Since 2008, Haoyang Environmental Technology has been advancing the science of soil stabilization and filtration with engineered woven and knitted geotextiles. Our high-strength polypropylene woven fabrics have a tensile strength of 200 kN·m and can be used for critical reinforcement of steep embankments and heavily loaded foundations; while our innovative knitted textiles provide multi-directional stress distribution and elongation of up to 25 times to accommodate complex settlement scenarios. Both product lines exceed ISO 10319 standards, with permeabilities ranging from 5×10⁻³ to 1×10⁻⁴ m·s, and are tailored for separation, filtration and drainage functions in global projects, including Brazilian highway bases, Saudi Arabian green belt anti-corrosion walls, and Vietnamese coastal revetments. Please request our technical selection guide to match the appropriate textile type, weight and permeability to your specific roadbed conditions.