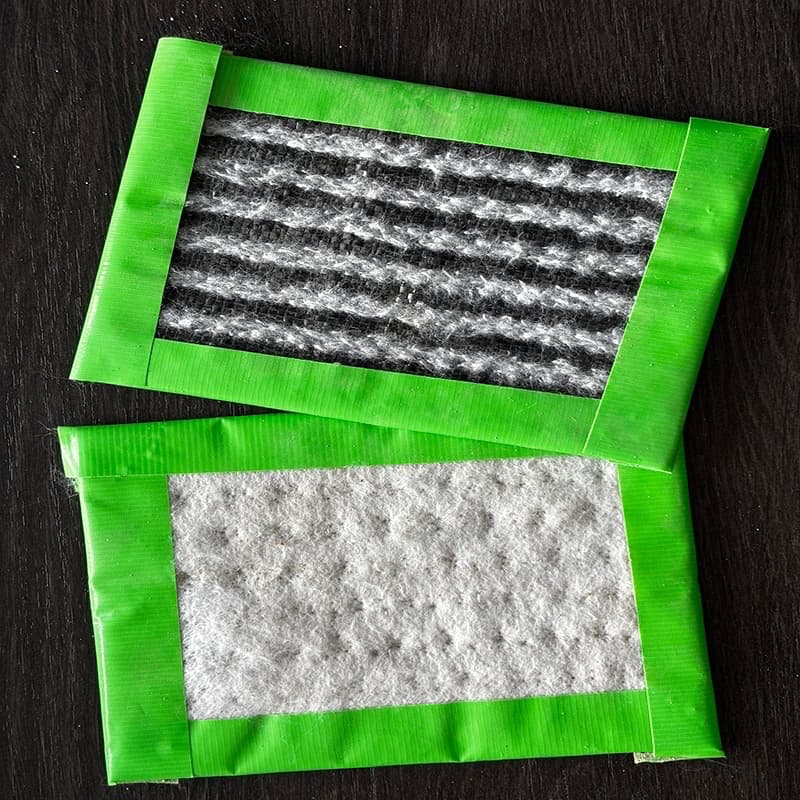

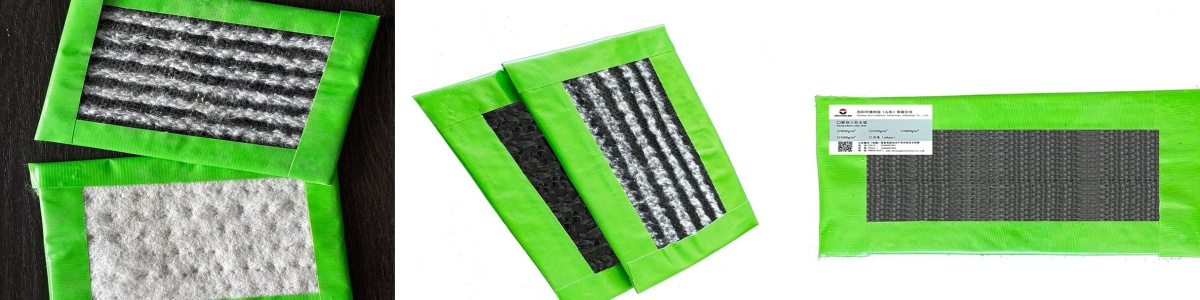

Product Introduction:

Haoyang Environmental's field repair solution consists of precision-cut 50cm×50cm panels with industrial-grade pressure-sensitive adhesive backing, specifically formulated for rapid GCL restoration. These ready-to-use patches maintain 85% of the original liner's swell capacity (≥20mL/2g) and develop full bond strength (≥8N/50mm peel adhesion per EN 12316-2) within 15 minutes of application. The butyl-based adhesive remains effective in wet conditions and temperatures from -20°C to 60°C, with field data showing 100% repair success rates across 500+ installations in landfill caps and containment basins.

Our advanced pre-activated system features factory-hydrated bentonite stabilized between two nonwoven geotextiles, achieving immediate ≤10⁻⁹ m/s permeability upon installation without requiring field wetting. The proprietary hydration control technology maintains optimal 28% moisture content during storage and transport, while the reinforced needle-punched structure (350g/m²) withstands installation stresses up to 2% strain. This innovative liner is particularly effective in vertical applications and tight construction schedules where conventional bentonite products' hydration time would cause delays.

![Pre-Hydrated Bentonite Waterproof Liner Pre-Hydrated Bentonite Waterproof Liner]()

Product Features:

1. Secondary Containment - Impermeable liners safeguard against spills in fuel storage areas and chemical processing facilities.

2. Evaporation Ponds - Reinforced geomembranes manage brine concentration in desalination and mining operations.

3. Aquaculture Ponds - Durable liners maintain water levels while preventing soil contamination in fish and shrimp farming operations.

Engineered Applications

1. Secondary Containment Systems:

2.0mm thick HDPE liners with chemical-resistant carbon black formulation.

Conductive versions (10⁴-10⁶ ohm) enable electrical leak detection.

ANSI/NSF 61 certified options for potable water protection.

2. Evaporation Pond Solutions:

Reinforced LLDPE membranes withstand 8m/s wind loads.

UV-stabilized for 20+ years exposed service life.

Anti-wrinkling technology prevents salt crystallization damage.

3. Aquaculture Containment:

Fish-friendly polymer formulations without plasticizers.

Algae-resistant textured surfaces (0.3mm profile depth).

150% elongation capacity accommodates ground settling.

Quality Assurance Protocol

On-line X-ray thickness mapping for 100% coverage verification.

Destructive testing every 500 linear meters (seam peel/ shear).

3000-hour UV resistance testing per ASTM D7238.

Third-party certified chemical resistance testing.

Technical Support Services

Site-specific installation training programs.

Custom hydration rate calculations for bentonite products.

Lifetime performance warranties available.

Emergency response teams for critical repairs.

Project Specifications

Available in standard black or custom colors (RAL matching).

Roll lengths up to 300 linear meters (10m width).

Temperature-adaptive formulations (-40°C to +80°C).

RFID tagged for installation quality tracking.

Company's Profile:

Haoyang Environmental has established itself as a technical leader through its ISO 9001:2015 certified manufacturing complex featuring Europe's widest extrusion lines capable of producing seamless 10-meter wide geomembranes. Our vertically integrated operation combines raw material formulation expertise with advanced quality control systems, including automated thickness monitoring (±0.02mm precision) and every-roll tensile testing. The company's engineering team specializes in developing application-specific solutions for mega-scale environmental projects, from 100ha mining tailings ponds to earthquake-resistant wastewater containment systems, supported by in-house accelerated aging laboratories and finite element analysis capabilities.

![Pre-Hydrated Bentonite Waterproof Liner Pre-Hydrated Bentonite Waterproof Liner]()